قائمة المنتجات

خط معالجة إنتاج الآلات البطاطا التلقائية للبطاطا

تفاصيل المنتج:

| مكان المنشأ: | هينان هوافود,الصين |

|---|---|

| اسم العلامة التجارية: | فوفود |

| شهادة: | ايزو,م,اس جي اس |

| رقم الموديل: | HDF10T |

قسط & شروط الشحن:

| أقل كمية ممكن طلبها: | 1مجموعات |

|---|---|

| سعر: | USD21350-30000 |

| تفاصيل التعبئة: | تعبئة خشبية قياسية أو حزمة عارية في حاوية 20 قدمًا |

| موعد التسليم: | 1أيام |

| شروط الدفع: | خطاب الاعتماد, د/أ, د/ب, تي/تي, ويسترن يونيون, موني جرام |

| قدرة العرض: | 15مجموعات 1 يوم |

ال خط معالجة إنتاج الآلات البطاطا التلقائية للبطاطا هو متقدم, حل آلي بالكامل مصمم لإنتاج البطاطا الفرنسية عالية الجودة بكفاءة لصناعة المواد الغذائية المجمدة وقطاعات الوجبات السريعة.

من تناول البطاطا الخام إلى العبوة النهائية, تم تصميم خط المعالجة هذا لتبسيط كل مرحلة من مراحل إنتاج البطاطا المقلية - ضمان نسيج مثالي, شكل موحد, لون ثابت, ومدى الحياة الافتتاحية. سواء كنت تقوم بإعداد مصنع جديد للمعالجة المقلية أو ترقية عملياتك الحالية, يوفر خط الإنتاج هذا حلًا قابلًا للتطوير وموثوقًا مصممًا لتلبية متطلبات المستهلكين المعاصرين من أجل المقرمش, ذهبي, والبطاطا المقلية اللذيذة.

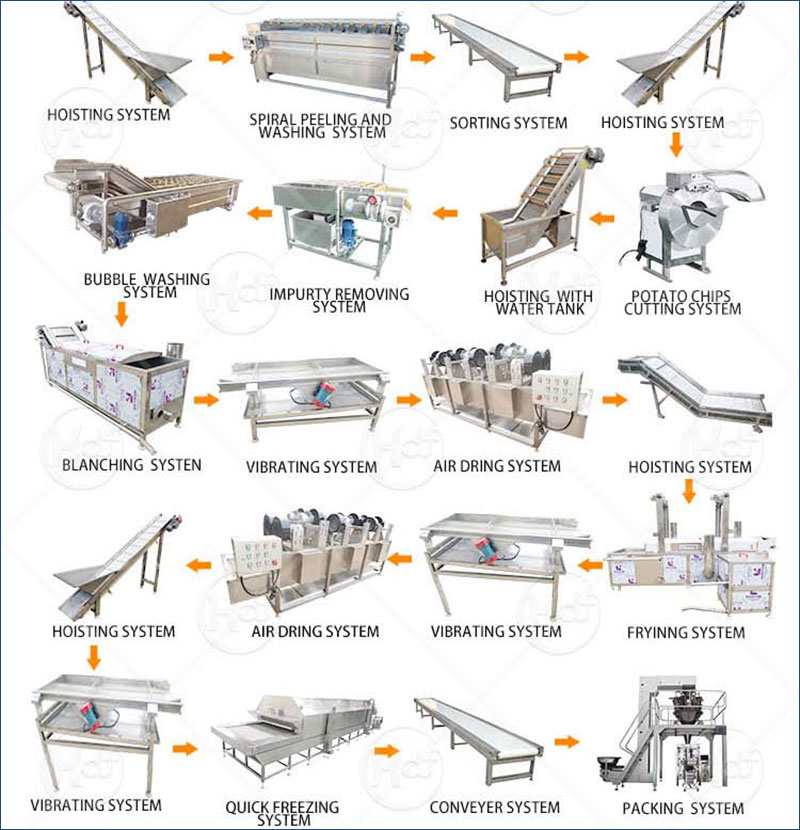

عملية تصنيع إنتاج البطاطس المقلية

غسل البطاطس & تقشير → الفرز ← القطع ← الشطف

1⃣ غسل البطاطا & آلة التقشير

يزيل الأوساخ تلقائيًا, الشوائب, وجلود البطاطا لتحضير نظيفة, البطاطا الجاهزة للعملية.

2⃣ فرز الناقل

نظام الفرز اليدوي أو البصري لإزالة البطاطا المعيبة وضمان توحيد الحجم قبل القطع.

3⃣ آلة قطع البطاطا

يقطع البطاطس بالتحديد إلى البطاطا المقلية الموحدة بأحجام قطع قابلة للتعديل لتلبية تفضيلات السوق.

4⃣ آلة الشطف

غسل النشا السطحي بشكل فعال, منع الالتصاق وضمان البطاطا المقلية أكثر هشاشة بعد القلي.

5machine machining blanching

مسبقات بطاطس بطاطس في درجات حرارة تسيطر عليها, الحفاظ على اللون, تحسين الملمس, وتوسيع عمر الصلاحية.

6machine آلة إزالة المياه

يزيل المياه السطحية الزائدة من البطاطس المقلية, تقليل رش الزيت وتحسين كفاءة القلي.

7⃣ آلة القلي المستمرة

بطاطس البطاطس في درجة حرارة محسنة ووقت لتحقيق الملمس المقرمش المطلوب واللون الذهبي.

8machine آلة deoiling

يستخدم قوة الطرد المركزي لإزالة الزيت الزائد, مما أدى إلى أخف وزنا, البطاطس المقلية الأكثر صحة مع أفضل فم.

9⃣ فريزر iqf (تجميد سريع فردي)

يجمد بسرعة مقلية للبطاطا المقلية لقفل النضارة, نَسِيج, ونكهة, مثالي للتخزين والتوزيع.

🔟 آلة التغليف التلقائية

يزن, أكياس, ويختام البطاطس المقلية في تنسيقات التعبئة المختلفة, جاهز لقنوات خدمة البيع بالتجزئة أو الخدمات الغذائية.

فيديو

مبدأ العمل

يتميز خط إنتاج البطاطس المقلية الأوتوماتيكي بمزايا الاستثمار المنخفض لمرة واحدة, استخدام طاقة منخفضة, وظائف متعددة, حجم صغير, ربح عالي, الاستخدام والصيانة المريحة. تتكون المجموعة الكاملة من المعدات من التنظيف والتقشير, تقطيع (يجرد), السلق, تجفيف, مزيج الماء والزيت القلي, ازالة الزيت, توابل, التعبئة والتغليف والمعدات المساعدة.

🌟 خط معالجة البطاطس الفرنسية سمات

- مؤتمتة بالكامل, خط الإنتاج المتكامل

أتمتة كاملة من تناول البطاطا الخام إلى العبوة النهائية. -

تكوين خط قابل للتخصيص & سعة الإخراج

يتيح التصميم المعياري تكوينات مرنة لمقاييس الإنتاج المختلفة. -

إدارة النفط المتقدمة & نظام الترشيح

يضمن الترشيح المتكامل جودة زيت القلي الأمثل وطول العمر. -

فعال الطاقة & بناء الفولاذ المقاوم للصدأ آمن الغذاء

تم تصميمه مع الفولاذ المقاوم للصدأ عالي الجودة للنظافة, متانة, وكفاءة الطاقة.

مزايا خط الإنتاج بطاطا البطاطا الفرنسية

-

عملية سلسة

سلس, سير العمل المستمر مع الحد الأدنى من التدخل اليدوي. -

وحدات & تصميم قابل للتطوير

يمكن تكييفها بسهولة مع احتياجات الإنتاج المختلفة-من الشركات الناشئة الصغيرة إلى المصانع واسعة النطاق. -

جودة الزيت الأمثل & انخفاض الاستهلاك

إدارة النفط الذكية تقلل من استخدام الزيت ويمتد حياة الزيت, تحسين كفاءة التكلفة. -

صحية & تصميم دائم

سهل التنظيف, مقاوم للتآكل, ومتوافقة تمامًا مع معايير معالجة الأغذية الدولية.

🎯 فوائد خط الإنتاج الفرنسي التلقائي

- كفاءة إنتاج أعلى & انخفاض تكاليف العمالة

الأتمتة يقلل بشكل كبير من الحاجة إلى العمل اليدوي وزيادة الإخراج. -

استثمار مرن & نمو الأعمال

اختر سعة الخط وفقًا للاحتياجات الحالية وزيادة الطلب مع زيادة الطلب. -

البطاطا المقلية الفرنسية ذات الذوق الفائق

جودة القلي المتسقة توفر متموجة, ذهبي, والبطاطا المقلية الأكثر صحة التي تلبي توقعات المستهلك الحديثة. -

امتثال السوق & إنتاج جاهز للتصدير

المعدات تجتمع HACCP, م, ومتطلبات إدارة الأغذية والعقاقير, السماح بالدخول الآمن إلى الأسواق العالمية.

📊 محطة معالجة البطاطس الفرنسية شهادة

- اعتمدها القادة العالميون

موثوق به واستخدامه من قبل الشركات المقلية الفرنسية المجمدة في أوروبا, جنوب شرق آسيا, والشرق الأوسط. -

قابلية التوسع المثبتة

خيارات السعة الإنتاجية من 300 كجم/ساعة إلى 3,000 كجم/ساعة - قابلة للتطوير مع نمو الأعمال. -

تم التحقق من وفورات التكلفة

تقرير العملاء يصل إلى 40% تخفيض في تردد استبدال النفط بفضل إدارة النفط المتقدمة. -

ضمان الجودة المعتمد

معتمد بالكامل لسلامة الأغذية العالمية (HACCP, م, FDA), مع التركيبات في أسواق دولية متعددة.

خاتمة

ال خط معالجة إنتاج الآلات البطاطا التلقائية للبطاطا هو الاستثمار المثالي للشركات التي تهدف إلى إنتاج بطاطس فرنسية مميزة تلبي توقعات المستهلك اليوم من أجل الجودة, نَسِيج, ونكهة. من قطع الدقة إلى القلي الخاضع للرقابة والتجميد السريع, تم تصميم كل مرحلة للحفاظ على الخير الطبيعي للبطاطا أثناء توصيل البطاطس الذهبية المقرمشة الشهيرة المحببة في جميع أنحاء العالم.

📩 على استعداد لرفع إنتاج البطاطس الفرنسية الخاصة بك?

👉 اتصل بنا اليوم للحصول على اقتراح مخصص, مواصفات مفصلة, ونصيحة الخبراء مصممة خصيصًا لاحتياجات المعالجة الخاصة بك!