LISTA DE PRODUCTOS

Línea industrial de frutas y vegetales con máquina de desagüe en línea

Detalles de producto:

| Lugar de origen: | Henan Huafood,Porcelana |

|---|---|

| Nombre de la marca: | HUAFOOD |

| Certificación: | YO ASI,CE,SGS |

| Número de modelo: | HDF6000 |

La línea industrial de lavado de frutas y verduras con la máquina de desagüe en línea es un conjunto de equipos automatizados que integran el lavado y la deshidratación, Diseñado para empresas de procesamiento de frutas y verduras, con el objetivo de lavar de manera eficiente y a fondo todo tipo de frutas y verduras. Consiste en una cinta transportadora de elevación, una sección de limpieza de burbujas, un área de enjuague en aerosol y un módulo de deshidratación en línea. Todo está hecho de acero inoxidable de grado alimenticio y es adecuado para cocinas centrales, Plantas de procesamiento de productos agrícolas, hoteles y grandes comedores. Este equipo puede mejorar significativamente la eficiencia de la limpieza, Reducir los costos laborales, y asegúrese de que los productos cumplan con los estándares de higiene más altos. Es una parte importante de las líneas de producción modernas de procesamiento de alimentos..

Parámetros de la línea de lavado de verduras

| Producción total de la línea de lavado de zanahorias. 500-1000 kg / h | ||

| Artículo | Fuerza | Tamaño |

| Lavadora de burbujas | 3.75kilovatios/380v/50Hz | 4000*1200*1300milímetros |

| máquina elevadora | 0.75kilovatios/380v/50Hz | 2000*1000*1900milímetros |

| Máquina de limpieza de rodillos de pelo | 2.0kilovatios/380v/50Hz | 2000*1000*1300milímetros |

| máquina vibratoria | 1.5kilovatios/380v/50Hz | 1500*1000*1300milímetros |

| máquina de secado al aire | 15kilovatios/380v/50Hz | 4000*1200*1400milímetros |

| Nota: Estos parámetros son convencionales y se pueden personalizar según las necesidades del cliente. | ||

Principio de trabajo de lavadora de frutas y verduras

Levantamiento y alimentación: El transportador introduce frutas y verduras en la sección de lavado a través de una correa de malla de acero inoxidable para garantizar un flujo continuo de materiales en la línea de producción.

Rollito de burbujas + aerosol: Use un generador de burbujas para crear caídas submarinas, más pulverización y cepillado de agua de alta presión para eliminar la suciedad, Residuos y sedimentos agrícolas.

Enjuague y ciclo de filtro: El sistema de pulverización de dos etapas y la filtración del ciclo se configuran para lograr la limpieza secundaria, mientras ahorra agua y protege el medio ambiente.

Deshidración: Después de lavar, Las frutas y verduras ingresan inmediatamente al módulo de deshidratación en línea (tales como cuchillo de aire del cinturón o deshidratación centrífuga) Para eliminar rápidamente la humedad de la superficie y prepararse para el corte o el envasado posteriores.

Video

Principio de funcionamiento de la línea de lavado de frutas y verduras

Proceso de lavado de frutas y verduras

1.El primer paso es poner las verduras y frutas que deben limpiarse en la lavadora de burbujas para su limpieza.;

2.el segundo paso es utilizar la cinta transportadora para transferir las frutas y verduras lavadas a la lavadora de rodillos para una limpieza secundaria y garantizar que las verduras estén limpias. 100%;

3.el tercer paso es retirar parte del agua de las frutas y verduras a través de la criba vibratoria;

4.El cuarto paso es retirar toda el agua de las frutas y verduras de la criba vibratoria al secador de aire.;

5.El quinto paso es cortar las frutas y verduras limpias según las necesidades.

Finalmente, según tus necesidades, puedes cortar, seco, congelar, embalar, etc..

Aplicaciones de líneas de lavado de frutas y verduras

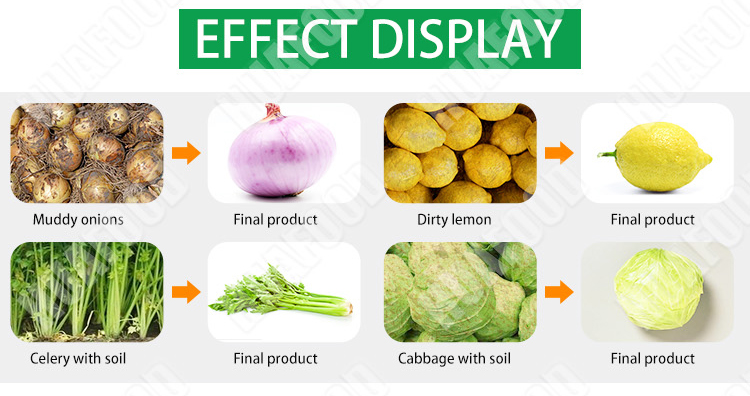

Nos especializamos en la producción de todo tipo de líneas de producción de frutas y verduras. Esta es una línea de producción completa., adecuado para varios tipos de verduras y frutas, como trozos de zanahoria, dátiles rojos, repollo, cebollas, agrios, palta, etc..

Escenarios aplicables: supermercados, restaurantes, plantas procesadoras de alimentos, plantas congeladas, productos de procesamiento de frutos secos.

Ventajas de la línea de lavado de verduras

Eficiente y ahorro de energía: La burbuja + El método de pulverización mejora la eficiencia de la descontaminación, y el sistema de agua circulante puede ahorrar más que 80% de agua.

Fuerte capacidad de procesamiento: Es adecuado para una amplia gama de capacidad de producción.. Una sola máquina puede procesar cientos a miles de kg/h, que es adecuado para fábricas de todos los tamaños.

Fácil de operar, seguro e higiénico: Regulación de velocidad de conversión de frecuencia, diseño sin ruido; La correa de malla de acero inoxidable se puede doblar/separar para una fácil limpieza y mantenimiento.

Características de la línea de lavado de frutas

Sistema de lavado integrado: integra la transmisión, lavado de burbujas, enjuague en rociado y deshidratación, y está diseñado para el diseño automatizado de la línea de ensamblaje.

Módulo ajustable: Velocidad de la cinta transportadora, El tiempo de lavado y la intensidad de deshidratación se pueden ajustar manualmente o mediante control PLC de acuerdo con diferentes materiales.

Material de grado alimenticio: Todo el cuerpo de la máquina está hecho de AISI 304 acero inoxidable, que cumple con los estándares internacionales de seguridad e higiene alimentaria

Conclusión

Esta línea industrial de frutas y lavado de verduras con máquinas de desagüe en línea recopila la esencia de la industria moderna de procesamiento de alimentos. No solo tiene ventajas obvias para lavar la eficiencia, Utilización de recursos hídricos, y facilidad de operación, pero también proporciona una solución única desde la alimentación frontal hasta la deshidratación de back-end. Si desea mejorar el nivel de automatización del taller, Reducir los costos operativos, y garantizar la seguridad y calidad del producto, Deje un mensaje en línea de inmediato 👇 para obtener parámetros de equipo detallados, Soluciones personalizadas y citas de proyectos. Tendremos ingenieros profesionales para responder a sus preguntas y proporcionar soporte general.!