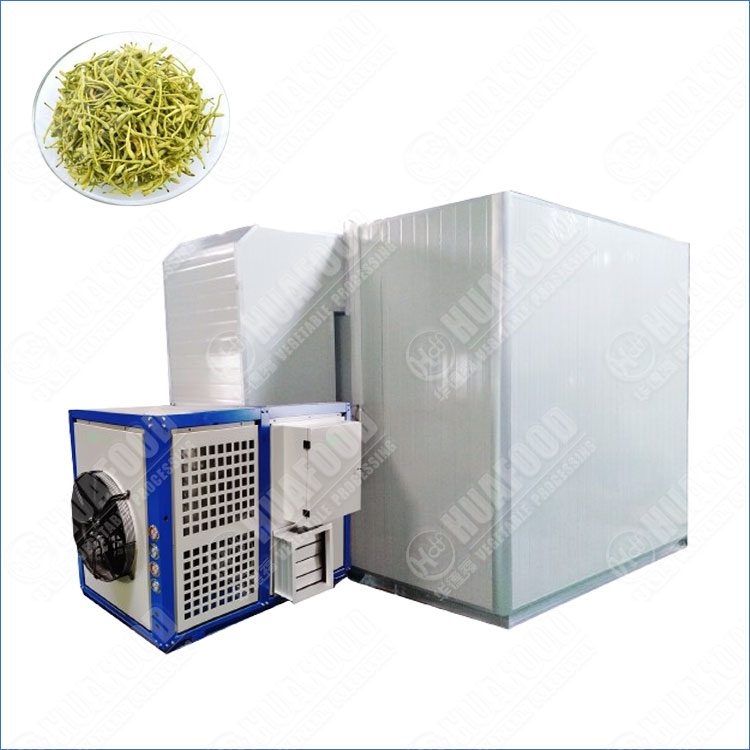

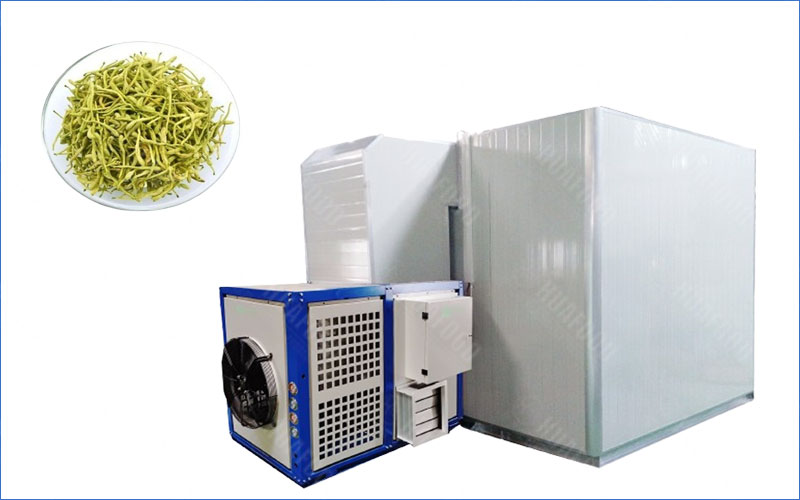

Mesin Pengering Honeysuckle Pompa Panas Dengan Teknologi Hemat Energi

Itu Honeysuckle Drying Machine is a professional-grade solution specifically engineered for the delicate dehydration of honeysuckle buds. Unlike conventional dryers that often scorch or discolor these sensitive medicinal herbs, our heat pump system is designed to protect the integrity of the honeysuckle. By maintaining the perfect balance between low-temperature drying and high-speed dehumidification, this machine ensures that the honeysuckle retains its natural green hue, floral fragrance, and maximum medicinal potency. It is the definitive choice for herbal medicine processors aiming for premium-grade, export-quality output.

Honeysuckle Drying Machine Working Principle

The core of this machine lies in its Advanced Heat Pump Dehumidification Technology. Instead of simply heating the air, the machine operates on a closed-loop system that extracts moisture from the honeysuckle at controlled temperatures. The evaporator absorbs the moisture from the drying chamber, turns it into water for drainage, and then the condenser releases clean, dry heat back into the cycle. Ini “moisture-stripping” method allows the honeysuckle to dry from the inside out at a steady 35°C ke 55°C, mimicking natural air-drying while preventing the oxidation and enzymatic browning that occurs with traditional high-heat methods.

Honeysuckle Drying Machine Advantages

-

Superior Color Retention: Our low-temperature technology effectively inhibits chlorophyll breakdown, ensuring the honeysuckle remains green and aesthetically superior.

-

High Medicinal Potency: By avoiding high-heat “flash” pengeringan, the machine preserves the maximum level of chlorogenic acid and essential oils within the flower buds.

-

75% Penghematan Energi: Compared to traditional electric heating tubes, the heat pump tech consumes significantly less power by recycling the latent heat of evaporation.

-

Kualitas Pengeringan Seragam: The optimized internal airflow ensures that every tray—from the top to the bottom of the rack—dries at the same rate, eliminating “titik panas” or uneven batches.

Fitur Pengering Pompa Panas

-

Intelligent PLC Control System: Features a customized “Honeysuckle Drying Curve” program that automatically manages 10+ stages of temperature and humidity for perfect color consistency.

-

Precise Humidity Sensor: Equipped with high-sensitivity sensors that monitor the internal environment in real-time, ensuring the buds reach the exact moisture content (usually 10-12%) for long-term storage.

-

Closed-Loop Air Circulation: The drying chamber is completely sealed, preventing any external dust or pollutants from contaminating the medicinal herbs.

-

Eco-Friendly SUS304 Trays: All contact parts and drying trays are made from food-grade stainless steel to ensure the honeysuckle meets strict pharmaceutical and food safety standards.

Honeysuckle Dehydrating Machine Benefits

-

Higher Market Prices: Green, well-preserved honeysuckle fetches a much higher price in the herbal market compared to dark or brittle, over-dried products.

-

Drastic Cost Reduction: Lower energy consumption and fully automated operation mean significantly reduced monthly utility bills and minimal labor requirements.

-

Zero Production Risk: No longer dependent on sunny weather; you can process your honeysuckle immediately after harvest, 24/7, preventing spoilage due to rain or high humidity.

-

Sustainable Production: No smoke, no exhaust, and no waste gas, making your facility compliant with the strictest global environmental regulations.

Kesimpulan

Itu Heat Pump Honeysuckle Drying Machine is more than just a dryer; it is a quality-preservation system. By combining energy-saving heat pump technology with specialized drying logic, we help you transform fresh honeysuckle into a premium medicinal product that stands out in the global marketplace.

Don’t let poor drying quality devalue your harvest. Are you looking for a custom drying capacity or a full production line layout? Tinggalkan kami pesan online hari ini! Our technical experts will provide you with a free energy-saving analysis and a professional quote tailored to your specific processing needs.