DAFTAR PRODUK

Jalur pencucian buah dan sayuran industri dengan mesin embun inline

Rincian Produk:

| Tempat asal: | Henan Huafood,Cina |

|---|---|

| Nama merk: | HUAFOOD |

| Sertifikasi: | ISO,CE,SGS |

| Nomor model: | HDF6000 |

Jalur pencucian buah dan sayuran industri dengan mesin embun inline adalah satu set peralatan otomatis yang mengintegrasikan pencucian dan dehidrasi, Dirancang untuk perusahaan pemrosesan buah dan sayuran, bertujuan untuk mencuci semua buah dan sayuran secara efisien dan menyeluruh. Itu terdiri dari sabuk konveyor pengangkat, Bagian Pembersihan Gelembung, Area pembilasan semprot dan modul dehidrasi inline. Keseluruhan terbuat dari stainless steel grade makanan dan cocok untuk dapur pusat, pabrik pengolahan produk pertanian, hotel dan kantin besar. Peralatan ini dapat secara signifikan meningkatkan efisiensi pembersihan, mengurangi biaya tenaga kerja, dan memastikan bahwa produk memenuhi standar kebersihan yang lebih tinggi. Ini adalah bagian penting dari jalur produksi pemrosesan makanan modern.

Parameter Jalur Pencucian Sayuran

| Total output dari jalur pencucian wortel 500-1000 kg / H | ||

| Barang | Kekuatan | Ukuran |

| Mesin Cuci Gelembung | 3.75kw/380v/50Hz | 4000*1200*1300mm |

| mesin pengangkat | 0.75kw/380v/50Hz | 2000*1000*1900mm |

| Mesin pembersih rol rambut | 2.0kw/380v/50Hz | 2000*1000*1300mm |

| mesin bergetar | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| mesin pengering udara | 15kw/380v/50Hz | 4000*1200*1400mm |

| Catatan: Parameter ini bersifat konvensional dan dapat disesuaikan dengan kebutuhan pelanggan | ||

Prinsip Kerja Mesin Cuci Buah dan Sayuran

Mengangkat dan memberi makan: Buah -buahan dan sayuran dimasukkan ke dalam bagian pencucian oleh konveyor melalui sabuk jala stainless steel untuk memastikan aliran bahan yang berkelanjutan di jalur produksi.

Bubble Rolling + menyikat semprotan: Gunakan generator gelembung untuk membuat jatuh di bawah air, ditambah penyemprotan air tekanan tinggi dan menyikat untuk menghilangkan kotoran, residu dan sedimen pertanian.

Bilas dan Siklus Filter: Sistem semprotan dua tahap dan penyaringan siklus diatur untuk mencapai pembersihan sekunder, sambil menghemat air dan melindungi lingkungan.

Dehidrasi: Setelah dicuci, Buah dan Sayuran Segera Masukkan Modul Dehidrasi Online (seperti pisau udara sabuk atau dehidrasi sentrifugal) Untuk dengan cepat menghilangkan kelembaban permukaan dan mempersiapkan pemotongan atau pengemasan berikutnya.

Video

Prinsip Kerja Jalur Pencucian Buah Dan Sayur

Proses pencucian buah dan sayuran

1.Langkah pertama adalah memasukkan sayuran dan buah-buahan yang perlu dibersihkan ke dalam mesin cuci bubble untuk dibersihkan;

2.langkah kedua adalah menggunakan ban berjalan untuk memindahkan buah dan sayuran yang sudah dicuci ke mesin cuci roller rambut untuk pembersihan sekunder guna memastikan sayuran bersih. 100%;

3.langkah ketiga adalah menghilangkan sebagian air dari buah dan sayuran melalui layar getar;

4.langkah keempat adalah membuang semua air dari buah dan sayuran dari layar getar ke dalam pengering udara;

5.langkah kelima potong buah dan sayur yang sudah dibersihkan sesuai kebutuhan

Akhirnya, sesuai dengan kebutuhan Anda, kamu bisa memotong, kering, membekukan, mengemas, dll..

Aplikasi Jalur Pencucian Buah Dan Sayur

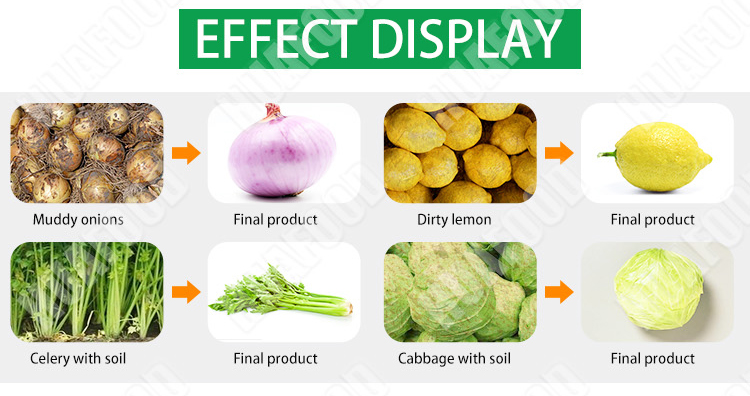

Kami mengkhususkan diri dalam memproduksi semua jenis lini produksi buah dan sayuran. Ini adalah lini produksi yang lengkap, cocok untuk berbagai jenis sayuran dan buah-buahan, seperti potongan wortel, tanggal merah, kubis, Bawang, jeruk, alpukat, dll..

Skenario yang berlaku: supermarket, restoran, pabrik pengolahan makanan, tanaman beku, produk pengolahan buah kering.

Keunggulan Jalur Pencucian Sayuran

Efisien dan hemat energi: Gelembung + Metode semprotan meningkatkan efisiensi dekontaminasi, dan sistem air yang bersirkulasi dapat menghemat lebih dari 80% air.

Kapasitas pemrosesan yang kuat: Ini cocok untuk berbagai kapasitas produksi. Satu mesin dapat memproses ratusan hingga ribuan kg/jam, yang cocok untuk pabrik dari semua ukuran.

Mudah dioperasikan, aman dan higienis: Peraturan Kecepatan Konversi Frekuensi, Desain bebas kebisingan; Sabuk mesh stainless steel dapat dilipat/terlepas agar mudah dibersihkan dan pemeliharaan.

Fitur Jalur Pencucian Buah

Sistem Cuci Terpadu: mengintegrasikan penyampaian, mencuci gelembung, Semprotkan pembilasan dan dehidrasi, dan dirancang untuk desain jalur perakitan otomatis.

Modul yang dapat disesuaikan: Kecepatan sabuk conveyor, waktu pencucian dan intensitas dehidrasi dapat disesuaikan secara manual atau dengan kontrol PLC menurut bahan yang berbeda.

Bahan grade food: Seluruh badan mesin terbuat dari AISI 304 besi tahan karat, yang memenuhi standar keamanan dan kebersihan pangan internasional

Kesimpulan

Garis pencucian buah dan sayuran industri ini dengan mesin embun inline mengumpulkan esensi dari industri pengolahan makanan modern. Itu tidak hanya memiliki keunggulan yang jelas dalam efisiensi mencuci, pemanfaatan sumber daya air, dan kemudahan operasi, tetapi juga memberikan solusi satu atap dari feeding front-end hingga dehidrasi back-end. Jika Anda ingin meningkatkan tingkat otomatisasi lokakarya, mengurangi biaya operasi, dan memastikan keamanan dan kualitas produk, Silakan tinggalkan pesan online segera 👇 untuk mendapatkan parameter peralatan terperinci, solusi dan kutipan proyek yang disesuaikan. Kami akan memiliki insinyur profesional untuk menjawab pertanyaan Anda dan memberikan dukungan serba!