DAFTAR PRODUK

Mesin peeling bawang peeler stainless steel untuk menghilangkan kulit

Rincian Produk:

| Tempat asal: | Henan Huafood, Cina |

|---|---|

| Nama merk: | HUAFOOD |

| Sertifikasi: | ISO,CE,SGS |

| Nomor model: | Disesuaikan |

| Aplikasi | banyak digunakan dalam industri pemrosesan sayuran. |

Perkenalan

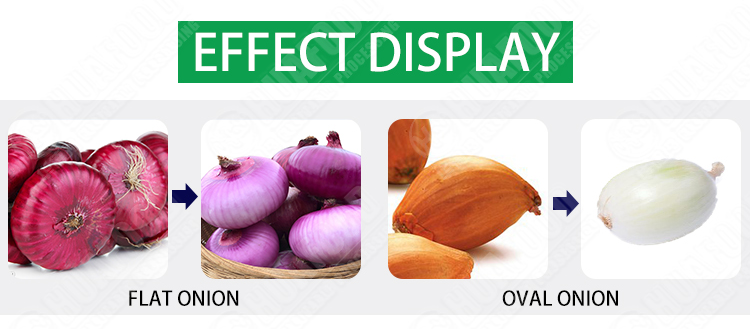

Mesin Pengupas Bawang Stainless Steel adalah solusi otomatis yang dirancang untuk mengupas kulit bawang pertama dan kedua tanpa merusak umbi. Mesin ini dapat menampung bawang mulai dari 45 mm sampai 105 diameter mm dan proses hingga 3,000 unit per jam, secara signifikan melampaui metode pengelupasan manual.

|

Model

|

HYC-500

|

|

Mengunggah

|

3 Sabuk

|

|

Ukuran

|

2150*1150*2000mm

|

|

Catu daya

|

380V, 50Hz,3Ph

|

|

Sumber gas

|

Lebih dari 1,0mpa

|

|

Kekuatan

|

1.52Kw

|

|

Keluaran

|

1500-2000kg/jam

|

|

Berat

|

320kg

|

Video

Prinsip bekerja

Mesin Peeling Onion mengadopsi metode pemrosesan mengelupas tanpa memotong akar. Dengan cara ini, Bawang kupasnya kecil dalam volume kulit, hasil tinggi, Dan interiornya bersih dan higienis tanpa polusi. Diperlukan bahwa bawang di negara bagian mana pun dapat dikupas pada satu waktu dan dihapus dengan bersih. Mesin telah banyak digunakan di industri pemrosesan sayuran.

Fitur

1. Penuh 304 Konstruksi Baja Tahan Karat Kelas Makanan

Semua bagian kontak—termasuk drum, pisau, dan rangka—dibuat dari baja tahan karat SUS304, memastikan ketahanan terhadap korosi dan pengoperasian yang higienis.

2. Sistem Pengupasan Pneumatik/Air-Jet

Memanfaatkan udara bertekanan yang diarahkan melalui roda skinning multi-port atau roller pneumatik untuk menghilangkan lapisan luar dengan lembut tanpa kerusakan akibat gesekan, menjaga keutuhan bawang merah .

3. Kecepatan Variabel & Kontrol Kedalaman

Dilengkapi dengan inverter frekuensi, operator dapat menyesuaikan kecepatan pengelupasan (500–1.500 rpm) dan mengatur tekanan udara (0.8–1,0 MPa) sesuaikan dengan bawang bombay kering atau basah dan kendalikan kedalaman kulitnya 0.2 mm sampai 0.5 mm .

4. Umpan Konveyor Berkelanjutan

Sabuk food grade mengangkut bawang melalui ruang pengupas dengan halus, aliran yang tidak terputus, memungkinkan kapasitas dari 600 kg/jam hingga 2,500 kg/jam tergantung modelnya .

5. Bilah Modular Pelepasan Cepat & Drum

Drum pengelupas modular dan rakitan bilah dapat masuk dan keluar tanpa alat, memfasilitasi pergantian yang cepat antar batch dan menyederhanakan prosedur sanitasi ;

Keuntungan

① Bawang tidak perlu dinilai, dan mereka dapat dikupas terlepas dari ukurannya, basah dan kekeringan. .

Otomasi Kulit, Penyelesaian Otomatis Satu kali dan Bersihkan Peeling.

③The “pengontrol korteks” dapat mengontrol kedalaman lapisan pengelupasan secara bebas, dan hanya mengupas kulit atau mengupas kulit kedua yang dapat dicapai.

④ Mesin menggunakan stainless steel 304, dengan umur panjang dan kemampuan anti-rust yang kuat.

Manfaat

Penghematan Tenaga Kerja: Menggantikan 8–10 pekerja per shift, menghemat biaya tenaga kerja hingga $5.000/bulan;

Kualitas Produk yang Konsisten: Pengelupasan yang seragam meningkatkan pemotongan hilir, memotong dadu, dan proses dehidrasi, meningkatkan hasil dan penampilan secara keseluruhan;

Mengurangi Waktu Henti: Suku cadang modular dan sistem pneumatik meminimalkan penyumbatan dan keausan mekanis, mengantarkan 16 jam/hari pengoperasian yang andal;

Peningkatan Keamanan Pangan: Desain baja tahan karat loop tertutup dengan komponen pelepasan cepat memungkinkan CIP menyeluruh (bersih di tempatnya) pembersihan, pertemuan CE, FDA, dan ISO 22000 standar;

Mesin Pengupas Bawang Pengupas Baja Tahan Karat Untuk Menghilangkan Kulit menggabungkan konstruksi kelas 304 yang kokoh, pengelupasan pneumatik hemat energi, dan kontrol yang mudah digunakan menjadi solusi lengkap untuk pengolah makanan modern. Ini memberikan efisiensi yang tak tertandingi, konsistensi kualitas, dan pengoperasian sanitasi—ideal untuk restoran, kantin, produsen makanan dehidrasi, dan operasi katering skala besar.

Siap untuk meningkatkan lini pengolahan bawang merah Anda?

👉 Tinggalkan kami pertanyaan online hari ini untuk spesifikasi detailnya, Konfigurasi Kustom, dan kutipan kompetitif!