DAFTAR PRODUK

Jalur Pengolahan Mesin Pengeringan Sayuran Akar Wortel Otomatis

Rincian Produk:

| Tempat asal: | Henan Huafood, Cina |

|---|---|

| Nama merk: | FUFOOD |

| Sertifikasi: | ISO,CE,SGS |

| Nomor model: | HDF100 |

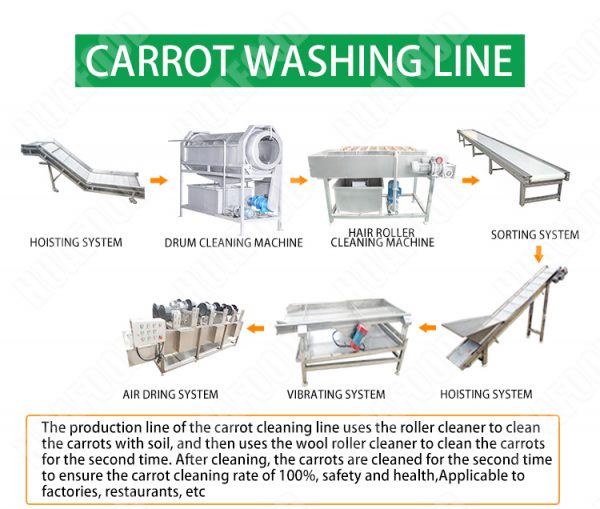

Pengenalan Jalur Pencucian Dan Pengeringan Wortel

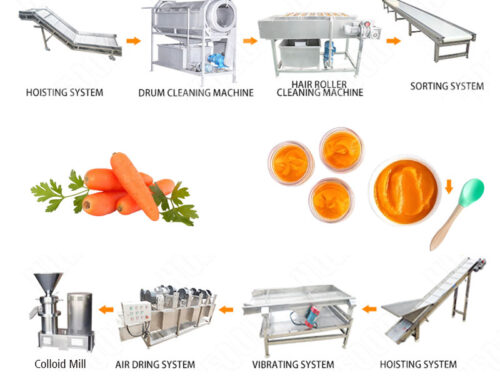

Itu jalur pemrosesan pengeringan pencucian wortel menggunakan roller cleaner untuk membersihkan Wortel dengan tanah, lalu gunakan pembersih rol wol untuk membersihkan wortel untuk kedua kalinya. Setelah dibersihkan, wortel dibersihkan untuk kedua kalinya untuk memastikan tingkat pembersihan wortel 100%, keamanan dan kesehatan,Berlaku untuk pabrik, restoran, dll.

Peralatan pengolahan wortel

| Total output dari jalur pencucian wortel 1000 kg / H | ||

| Barang | Kekuatan | Ukuran |

| mesin pengangkat | 0.75kw/380v/50Hz | 2000*1000*1900mm |

| Mesin pembersih drum | 3.75kw380v/50Hz | 3000*1100*2200mm |

| Pembersihan rol rambut mesin |

2.0kw/380v/50Hz | 2000*1000*1300mm |

| mesin sortir | 0.75kw/380v/50Hz | 3000*900*900mm |

| mesin pengangkat | 0.75kw/380v/50Hz | 2000*800*1600mm |

| mesin bergetar | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| mesin pengering udara | 15kw/380v/50Hz | 4000*1200*1400mm |

| Catatan: Parameter ini bersifat konvensional dan dapat disesuaikan dengan kebutuhan pelanggan | ||

Video Mesin Cuci Wortel

Prinsip Kerja Jalur Pencucian Wortel

Wortel dalam alur pembersih terendam air, melekat pada permukaan sejumlah besar potongan tanah yang hilang, ban berjalan ke saluran masuk mesin cuci drum, bahan pembersih ke dalam hopper ke dalam drum yang berputar, putaran drum di kolam, penggunaan pemisahan pembersihan gravitasinya sendiri sebagai penggerak, untuk mewujudkan bahan pembersih otomatis.

Wortel bergerak maju sepanjang dinding roller. Selama pergerakan, wortel selalu dicuci dengan air, gesekan antar wortel, penyikatan antara putaran dan gesekan antara bahan pembersih dan dinding roller, dan proses pembersihan permukaan wortel selesai di bawah aksi bersama.

Proses Pembersihan Sayuran Akar Wortel

- Langkah pertama masukkan wortel yang akan dicuci ke dalam mesin cuci bubble;

- Langkah kedua adalah menggunakan ban berjalan untuk memindahkan wortel yang sudah dicuci ke drum mesin cuci untuk pencucian kedua guna memastikan sayurannya 100% membersihkan;

- Langkah ketiga adalah membuang sebagian air pada wortel melalui saringan getar;

- Langkah keempat adalah mengalirkan semua air dari wortel pada shaker ke dalam pengering udara;

- Langkah kelima potong wortel yang sudah dicuci bersih sesuai kebutuhan

Akhirnya, sesuai dengan kebutuhan Anda, kamu bisa memotong, kering, membekukan, mengemas, dll..

Fitur Jalur Pengolahan Pencucian Wortel

Desain jalur perakitan multi-tahap

Mengintegrasikan penghilangan lumpur awal, pembersihan gelembung, pengelupasan sikat, penyemprotan bertekanan tinggi dan pengeringan udara untuk mencapai pemrosesan berkelanjutan;

304 bodi baja tahan karat food grade

Seluruh lini mengadopsi baja tahan karat SUS304, yang tahan korosi, mudah untuk dibersihkan, dan memenuhi standar ekspor Eropa dan Amerika;

Sistem pembersihan gelembung efisiensi tinggi

Tangki gelembung menggunakan penggulungan yang kuat untuk menghilangkan kotoran permukaan, dan dengan perangkat penyemprotan multi-titik, tingkat pembersihannya setinggi 95%;

Modul pengelupasan sikat yang dapat disesuaikan

Mengadopsi rol sikat lembut dan keras untuk secara efektif menghilangkan epidermis dan kotoran permukaan tanpa merusak rimpang;

Sistem penyemprotan dan pengeringan udara bertekanan tinggi

Dikombinasikan dengan pistol air bertekanan tinggi dan pisau udara bersuhu konstan, dehidrasi cepat dan pengeringan memberikan kebersihan, produk bebas tetesan untuk penyortiran dan pengemasan selanjutnya;

Penyortiran dan penolakan yang cerdas

Dapat dikonfigurasi dengan perangkat penyortiran getaran atau rol untuk menolak rimpang yang tidak memenuhi syarat menurut ukuran atau berat untuk memastikan konsistensi produk jadi;

Manfaat Garis Pembersih Wortel

Meningkatkan kualitas produk: pencucian seragam dan pengeringan cepat mengurangi pertumbuhan mikroba, memastikan wortel dan sayuran akar lainnya memiliki warna cerah dan rasa segar.

Mempersingkat siklus pemrosesan: pemrosesan otomatis ujung ke ujung mengurangi beberapa proses tradisional menjadi satu garis lurus, meningkatkan efisiensi produksi sebesar 2-3 kali.

Meningkatkan keamanan pangan: semua desain sabuk baja tahan karat dan food grade, sejalan dengan CE, Standar FDA dan HACCP, mudah untuk diperiksa dan mematuhi peraturan kebersihan.

Mengurangi biaya pemeliharaan: rol sikat yang tahan aus dan motor berkualitas tinggi mengurangi tingkat kegagalan, dan investasi pemeliharaan tahunan berkurang sebesar 40%.

Jalur pemrosesan pencucian wortel ini merekonstruksi aliran pemrosesan sayuran akar melalui teknologi cerdas, mengompresi pembersihan tradisional, penyortiran, dan proses pengeringan yang memerlukan 12 orang untuk menyelesaikan operasi jalur perakitan yang sepenuhnya otomatis. Hal ini sangat cocok untuk perusahaan yang mengupayakan peningkatan kapasitas dan standardisasi kendali mutu. Dengan mengurangi intervensi manual, mengurangi kerugian bahan baku, dan memastikan keamanan pangan, ini membantu Anda membangun daya saing inti dalam perdagangan produk pertanian global.

Siap mengoptimalkan lini pembersih sayuran akar wortel Anda?

👉 Tinggalkan pesan online untuk mendapatkan detail rencana dan penawaran harga. Tim perdagangan luar negeri kami akan memberi Anda layanan khusus satu atap!