ELENCO PRODOTTI

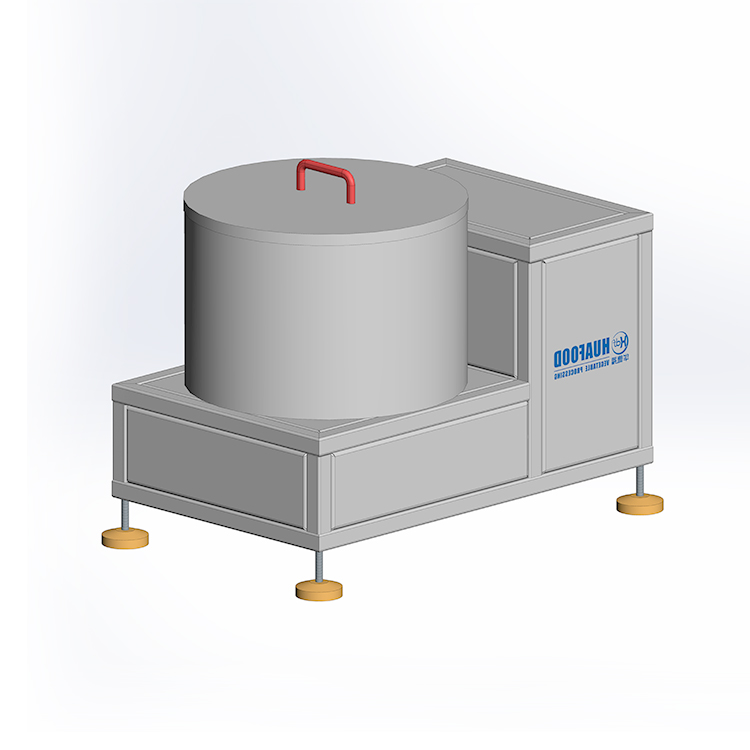

Macchina centrifuga di cibo per alimenti fritti per la rimozione dell'olio HTY-400

Dettagli del prodotto:

| Luogo d'origine: | Henan Huafood,Cina |

|---|---|

| Marchio: | HUAFOOD |

| Certificazione: | ISO,CE,SGS |

| Numero di modello: | HDF100 |

IL Macchina centrifuga per la disoleazione degli alimenti fritti è progettato specificamente per le esigenti esigenze dei produttori di snack fritti. Questa attrezzatura di precisione affronta la sfida principale dell'eccessiva ritenzione di olio in prodotti come le patatine, patatine alla banana, tagliatelle fritte, e pellet estrusi – che incidono direttamente sul gusto, struttura, percezione della salute, durata di conservazione, e costi di produzione.

Parametri della macchina per la deoliazione centrifuga degli alimenti

| Modello | Dimensione | Peso | Energia | Produzione |

| HTY-400 | 1000*500*700mm | 90kg | 1.1kw/380v | 300kg/h |

| HTY-500 | 1100*600*7500mm | 100kg | 1.5kw/380v | 400kg/h |

| HTY-600 | 1200*700*750mm | 120kg | 2.2kw/380v | 500kg/h |

Video sulla macchina per la disoleazione centrifuga degli alimenti fritti

Principio di funzionamento della macchina centrifuga a olio

La disoleatrice centrifuga è dotata di sistema antiurto, e l'apparecchiatura non vibra, non funziona, e ha una forte stabilità durante la disoleazione. È adatto alla disidratazione di cibi e verdure dopo la pulizia e la disoleazione dei fritti. Il componente principale della disoleatrice è il contenitore interno, e piccoli fori sono distribuiti attorno al contenitore interno, e nel contenitore interno vengono posti gli alimenti e le verdure da disoleare. Il motore fa ruotare il contenitore interno ad alta velocità attraverso il nastro. Perciò, viene generata una grande forza centrifuga, e l'olio viene espulso attraverso un piccolo foro nel contenitore interno, e viene raccolto e scaricato uniformemente.

Il dispositivo di rimozione dell'olio centrifugo ha un design strutturale ragionevole, elimina efficacemente l'angolo morto dei servizi igienico-sanitari, ha una transizione graduale delle parti strutturali, adotta l'acciaio inossidabile per produrre parti strutturali esterne, elementi di fissaggio e tamburi rotanti, e ha un tipo di fatturato in alto, in modo che lo spazio intermedio tra il corpo della centrifuga e il tamburo rotante possa essere pulito a fondo; Il diametro della maglia del contenitore interno deve essere forato con precisione al laser in base alle esigenze del cliente, liscio e privo di sbavature. L'uscita dell'olio con un design ragionevole della fusoliera può scaricare in modo tempestivo ed efficace l'olio e l'acqua separati nel contenitore designato, e l'ambiente sanitario è pulito e ordinato. Può essere abbinato ad una friggitrice, una macchina per stagionare e una macchina confezionatrice per formare una catena di montaggio; Alta efficienza, risparmio di tempo e risparmio di costi di manodopera; L'intero set è realizzato in acciaio inossidabile, che è facile da montare, smontare e pulire ed è conforme alla sicurezza alimentare.

Caratteristiche della macchina per la disoleazione

Alta efficienza, risparmio di tempo e risparmio di costi di manodopera;

Può essere abbinato ad una friggitrice, una macchina per stagionare e una macchina confezionatrice per formare una catena di montaggio;

L'intero set è realizzato in acciaio inossidabile, che è facile da montare, smontare e pulire ed è conforme alla sicurezza alimentare.

Il diametro della maglia del contenitore interno deve essere forato con precisione al laser in base alle esigenze del cliente, liscio e privo di sbavature.

L'uscita dell'olio con un design ragionevole della fusoliera può scaricare in modo tempestivo ed efficace l'olio e l'acqua separati nel contenitore designato, e l'ambiente sanitario è pulito e ordinato.

Il dispositivo di rimozione dell'olio centrifugo ha un design strutturale ragionevole, elimina efficacemente l'angolo morto dei servizi igienico-sanitari, ha una transizione graduale delle parti strutturali, adotta l'acciaio inossidabile per produrre parti strutturali esterne, elementi di fissaggio e tamburi rotanti, e ha un tipo di fatturato in alto, in modo che lo spazio intermedio tra il corpo della centrifuga e il tamburo rotante possa essere pulito a fondo;

Vantaggi della disoleatrice centrifuga

Specifico per Snack Fritti:

Aumenta le vendite: Consegna un addetto alle pulizie, un morso più croccante che soddisfa le moderne preferenze salutistiche senza sacrificare il piacere.

Tagliare i costi: Recupera fino a 30% più olio da riutilizzare, riducendo significativamente la spesa maggiore per le materie prime.

Estendi la freschezza: La riduzione dell'olio riduce al minimo l'ossidazione, portando a una durata di conservazione più lunga e a minori resi.

Semplifica la produzione: Deoliazione più rapida (secondi contro. minuti) si integra perfettamente nelle linee di frittura ad alto volume.

Prova di una piccola centrifuga

Specifico per Snack Fritti: Installato in oltre 200 linee di lavorazione degli snack in tutto il mondo. Certificato CE, FDA, e gli standard GMP. ROI comprovato: Rapporto dei clienti <12 periodi di ammortamento mensili grazie al risparmio di petrolio e alla riduzione dei rifiuti. I test di laboratorio mostrano costantemente una rimozione dell'olio superficiale ≥95% su prodotti come patatine fritte e bignè estrusi.

Conclusione

Trasforma oggi stesso la tua produzione di snack fritti!

La macchina per la disoleazione centrifuga degli alimenti fritti non è solo un'attrezzatura: è il tuo partner strategico per produrre prodotti di qualità superiore, snack fritti economici che vincono sul mercato. Sperimenta in prima persona come il controllo preciso dell'olio sblocca un gusto migliore, margini più elevati, e clienti più felici.

Pronti per ottimizzare la qualità e la redditività dei vostri snack fritti?

➔ Contattaci SUBITO GRATUITAMENTE, preventivo personalizzato per soluzioni di disoleazione!

➔ Fare clic “Richiedi un preventivo” oppure invia un'e-mail a sales@huafoodmachine.com per discutere le tue specifiche esigenze di produzione di snack!

Lascia che ti mostriamo l'esatto risparmio di petrolio e di costi che puoi ottenere.