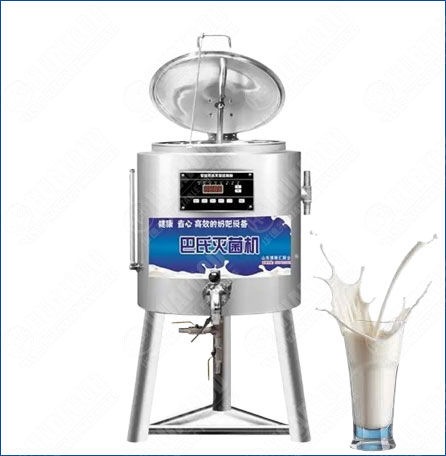

Macchina commerciale per pastorizzare il latte di piccole dimensioni con controllo preciso della temperatura

Milk is an extremely nutritious beverage, but its high protein and fat content also makes it a breeding ground for microorganisms and highly sensitive to temperature changes. To achieve the optimal balance between eliminating pathogenic bacteria and preserving the original nutrients of milk (such as whey protein and vitamins), pasteurization technology was developed.

Our Commercial Small Milk Pasteurizer Machine with Precise Temp Control is designed specifically for commercial applications such as milk bars, small dairies, laboratories, or startup dairy businesses. The core advantage of this machine lies in its high-precision temperature control system, which can stably maintain the milk temperature within the critical temperature range required for pasteurization (per esempio., between 62℃ and 85℃), ensuring thorough sterilization while maximizing the preservation of the milk’s natural flavor and nutritional value. The entire machine features a commercial-grade design and corrosion-resistant materials, making it the ideal choice for achieving high-quality, safe milk processing in limited spaces.

Small Milk Pasteurizer Machine Working Principle

The commercial small milk pasteurizer machine utilizes the principle of batch pasteurization, achieving pasteurization through precise control of time and temperature.

Water Bath Heating and Circulation: The equipment employs a double or triple-layered jacketed structure. The inner layer holds the milk, while the jacket layer (or water bath layer) is filled with water as a heat transfer medium. Upon startup, electric heating elements uniformly heat the water in the jacket, with the water temperature precisely controlled to be slightly above the target pasteurization temperature.

High-Precision Temperature Monitoring and Control: Built-in high-sensitivity platinum resistance or thermocouple sensors continuously monitor the internal temperature of the milk. The control system (PID controller) automatically adjusts the heating power according to the preset pasteurization program (per esempio., 65℃ for 30 minuti), ensuring a stable milk temperature curve and preventing localized overheating that could denature milk proteins.

Holding Time for Pasteurization: Once the milk reaches the set pasteurization temperature, the system precisely maintains this temperature for a specific duration (Hold Time) to effectively kill pathogenic microorganisms such as E. coli and Salmonella in the milk.

Rapid Cooling: After pasteurization is complete, the control system automatically initiates a cooling cycle. By replacing the hot water in the jacket with circulating cold water or ice water, the milk temperature is rapidly reduced to a preservation temperature below 4℃, immediately stopping further heating effects on milk quality and ensuring product freshness.

Vantaggi della piccola macchina per pastorizzare il latte

Maximizes Milk Nutrition and Flavor Retention: Precise temperature control and gentle heating effectively prevent protein denaturation and vitamin loss in milk, ensuring that the pasteurized milk retains a taste and nutritional value close to that of raw milk.

Ensures Food Safety and Regulatory Compliance: Accurate temperature and time control guarantee the complete elimination of pathogenic bacteria, allowing small commercial users to easily comply with local and international food safety regulations.

Suitable for Multi-Product Dairy Processing: This equipment is not only suitable for fresh milk but can also be used for base pasteurization before yogurt fermentation, and for pasteurizing cream or ice cream mixes by adjusting the program.

Exceptional Durability and Hygienic Cleanability: The SUS304 material is durable and corrosion-resistant, and the simple internal design and removable stirrer make cleaning and maintenance exceptionally easy and efficient.

Commercial Milk Pasteurizer Features

High-Precision PID Temperature Control System: Utilizing advanced PID algorithms and high-sensitivity sensors, this system controls milk temperature fluctuations within ±0.5℃, perfectly accommodating milk’s sensitivity to temperature changes.

Commercial-Grade SUS304 Stainless Steel Structure: All parts in contact with milk are made of food-grade SUS304 stainless steel, ensuring superior resistance to acid and alkali corrosion and meeting stringent food hygiene requirements.

Efficient Triple-Layer Jacketed Design: A three-layer structure (milk layer, heat transfer medium layer, insulation layer) provides uniform and gentle heating and rapid cooling switching, protecting heat-sensitive nutrients in the milk.

Integrated Agitation and Venting Device: Equipped with a low-speed, hygienic agitator, this device ensures uniform temperature distribution during milk heating, preventing localized “rovente”; a vent is also included to prevent excessive pressure buildup within the jacket.

Industrial Pasteurizer Benefits

Enhances Brand Trust and Market Competitiveness: Providing customers with safe, high-quality milk processed through high-precision pasteurization quickly builds brand reputation and gains consumer favor.

Optimizes Operation Costs and Efficiency: Automated temperature control and efficient heating and cooling systems reduce the need for manual monitoring and energy consumption, while also shortening batch processing times.

Quick Return on Investment (ROI): Suitable for small-scale businesses, the reasonable initial investment cost, coupled with stable and high-quality product output, allows for rapid profitability.

Flexible Response to Market Demands: The intermittent small-batch processing mode allows users to flexibly adjust production based on daily or seasonal demand, reducing inventory buildup and waste.

Conclusione

Our Commercial Small Milk Pasteurizer Machine with Precise Temperature Control is an ideal device designed specifically for small-scale dairy businesses, combining high precision, high hygiene standards, e alta efficienza. It perfectly addresses the stringent temperature control requirements in milk processing, making it crucial for producing safe, nutritious, and high-quality milk.

Don’t let unreliable temperature control compromise your milk quality and brand reputation!

Take action now! Leave a message online or contact our expert team via email to get detailed technical specifications, customized capacity options, and the latest pricing information for this small commercial pasteurizer! Ensure your milk products stand out in the market!