ELENCO PRODOTTI

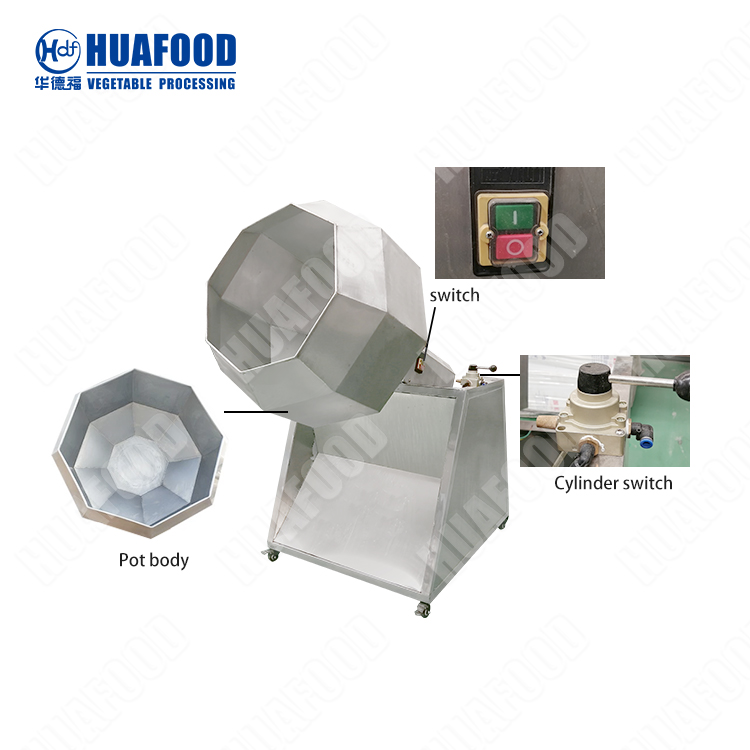

Materiale Ss per macchina per aromatizzare le patatine fritte di anice stellato piccolo

Dettagli del prodotto:

| Luogo d'origine: | Henan Huafood,Cina |

|---|---|

| Marchio: | HUAFOOD |

| Certificazione: | ISO,CE,SGS |

| Numero di modello: | HBT-500 |

Pagamento & Termini di spedizione:

| Quantità di ordine minimo: | 1imposta |

|---|---|

| Prezzo: | USD 1850-2150 |

| dettagli sul confezionamento: | Imballaggio standard in legno O pacchetto nudo in container da 20 piedi |

| Tempi di consegna: | 2giorni |

| Termini di pagamento: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Capacità di fornitura: | 5imposta 2 giorni |

La piccola macchina per aromatizzare le patatine con anice stellato (Materiale SS) è una macchina appositamente studiata per la stagionatura, spolverare, e ricoprire le patatine. È ideale per piccoli lotti o linee di produzione di piccole e medie dimensioni. Realizzato interamente in acciaio inossidabile (tipicamente alimentare 304/316), nebulizza e miscela uniformemente aromi granulari e in polvere (come le cinque spezie, anice stellato, cumino, chili, e formaggio), garantendo una copertura aromatica coerente e controllabile per ogni chip. Questa macchina è particolarmente adatta per condire le noci, patatine, e snack, fungendo da collegamento cruciale tra la frittura e il confezionamento.

Parametro della macchina per condimenti per patatine fritte

| Modello | Dimensione | Peso | Energia | Produzione |

| HBT-300 | 1000* 800*1300mm | 130kg | 1.1chilowatt | 300kg/h |

| HBT-500 | 1100* 1000* 1300mm | 150kg | 1.5chilowatt | 500kg/h |

| Conditrice a scarico manuale personalizzabile | ||||

Principio di funzionamento della macchina per condire le patatine

Questa macchina per condimenti riveste principalmente le patatine con sapore attraverso i seguenti passaggi e principi:

Alimentazione e burattatura delle patatine fritte

Dopo la disoleazione/essiccazione all'aria, le patatine vengono poste nel tamburo ottagonale di condimento. Quando la macchina viene avviata, il tamburo o le pale di miscelazione interne ruotano lentamente, facendo sì che i trucioli ruotino e girino continuamente all'interno del tamburo.

Spruzzatura di condimenti/Spargimento di polvere

Durante il processo di burattatura, un dispositivo di polverizzazione/spruzzatura spruzza/miscela la polvere di condimento secco o il liquido di condimento umido (come olio e spezie) nel tamburo, garantendo un contatto completo con i trucioli.

Miscelazione/Rivestimento uniforme

La rotazione del tamburo e i meccanismi di miscelazione interni (come le lame a spirale, agitatori statici, e miscelazione assistita da vibrazioni) cappotto, cadere, e ricoprire le patatine con il condimento fino a ottenere un rivestimento uniforme.

Scaricare/filtrare il condimento in eccesso

Dopo una stagionatura uniforme, la macchina utilizza uno scarico inclinato, uno schermo vibrante, o un setaccio per filtrare la polvere in eccesso e recuperare il condimento riutilizzabile. Le patatine vengono poi convogliate fuori dalla macchina per il confezionamento o il processo successivo.

Configurazioni opzionali / Sistema di recupero

Alcuni modelli possono essere dotati di un sistema di aria assistita/di ritorno per rimuovere la polvere e recuperare la polvere in eccesso; o con scarico automatico opzionale/classificazione automatica/riscaldamento/controllo dell'umidità per garantire una migliore adesione dell'aroma in polvere e ridurre al minimo la perdita di polvere.

Questo “cadendo + spolverare/spruzzare + miscelazione” è il metodo di condimento/rivestimento più comunemente utilizzato nel settore delle patatine e in altri settori alimentari soffiati/fritti.

video

Applicazione della macchina per aromatizzare le patatine fritte

La piccola macchina per aromatizzare le patatine può essere utilizzata per condire cibi fritti, arachidi, soia, noce, patatine, eccetera. La miscelatrice per condimenti per verdure e ottagonali può rendere uniforme la lavorazione del cibo e del condimento in 5-6 minuti. La miscelatrice per condimenti ottagonale può scaricare il cibo inclinandosi automaticamente; La miscelatrice per condimenti ottagonale ha il carattere di bassa rumorosità grazie al funzionamento e all'aspetto bello.

Caratteristiche della macchina per aromatizzare le patatine

Corpo in acciaio inox per uso alimentare (SS 304/316)

Parti che entrano in contatto con i trucioli, la canna, e il meccanismo di miscelazione sono tutti realizzati in acciaio inossidabile, rendendoli resistenti alla corrosione, facile da pulire, e igienico.

Meccanismo di velocità/agitazione del barilotto ottagonale regolabile

La canna ottagonale è dotata di velocità regolabile, e la pala per mescolare, lama a spirale, e il piatto di rotolamento può essere personalizzato o regolato per adattarsi a diversi spessori di trucioli e tipi di condimento.

Design compatibile con polvere secca/spray/miscela

Può spruzzare condimenti in polvere secca, condimenti liquidi, o condimenti a base di olio, ospitare una varietà di metodi di stagionatura per una maggiore flessibilità.

Scarico inclinato/recupero filtro

La macchina è dotata di un meccanismo di scarico inclinato o di scarico automatico, dotato di dispositivo di vaglio/recupero per la raccolta dei condimenti staccati.

Sistema di soffiaggio aria/recupero polveri (Opzionale)

L'aria soffia via la polvere sciolta, riduce la polvere, migliora la copertura, e recupera la polvere utilizzabile.

Vantaggi della macchina per condire le patatine con anice stellato

Copertura uniforme del sapore/Elevata adesione

Il tamburo ottagonale, meccanismo di miscelazione, e la velocità controllata combinata con un metodo di spruzzatura garantisce una distribuzione uniforme del condimento, riducendo le macchie di sapore irregolari.

Bassa rottura/mantiene l'integrità del chip

Il metodo di miscelazione flessibile, velocità regolabile, e l'azione delicata riducono al minimo la rottura e la frammentazione del truciolo.

Compatibilità flessibile con una varietà di condimenti

Può gestire una varietà di forme di condimento, comprese polveri e liquidi (diluito o spruzzato), accogliere sapori diversi, piccoli lotti, e cambiamenti di produzione.

Facile da pulire/bassa manutenzione

La costruzione in acciaio inossidabile e il design modulare (coperchio del fusto rimovibile, lame di miscelazione, ugelli spruzzatori, filtri, ecc.) facilitano la pulizia e la manutenzione.

Materiale efficiente/Rifiuti ridotti

Il sistema di recupero/filtrazione/soffiaggio riduce gli scarti di stagionatura e recupera le polveri non aderenti, migliorare l’utilizzo e ridurre i costi.

Vantaggi & Prova

Migliorare la consistenza e la qualità del sapore del prodotto

Le patatine vengono condite in modo uniforme e coerente, migliorare la qualità del prodotto finale e la reputazione sul mercato.

Ridurre i tassi di difettosità/rottura

L'elevata integrità e la frammentazione minima riducono le perdite e migliorano la resa effettiva.

Risparmiare sui costi/Ridurre gli sprechi

Recuperare il condimento staccato, ridurre la perdita di condimento, e semplificare la manutenzione delle apparecchiature, riducendo così il costo unitario dell'aroma.

Accelerare la produzione/Aumentare la capacità

Il condimento automatizzato del barile ottagonale può essere sincronizzato con la linea di produzione di patatine, migliorare l’efficienza complessiva della linea.

Semplifica i cambi di linea/Flessibilità

Per linee di produzione multigusto/piccoli lotti, la configurazione flessibile dell’apparecchiatura (commutazione spray/polvere secca, velocità regolabile) semplifica i cambi di linea.

Conclusione

Insomma, la piccola macchina per aromatizzare le patatine all'anice stellato (Materiale SS, acciaio inossidabile per uso alimentare, struttura a botte ottagonale) è specificatamente studiato per aromatizzare patatine ed altri cibi fritti. Presenta caratteristiche chiave come un sistema di stagionatura a botte ottagonale, velocità regolabile e meccanismo di miscelazione, compatibilità polvere/spray, un sistema di scarico/recupero, e funzionamento assistito dall'aria. Questi vantaggi includono una distribuzione uniforme del sapore, bassa rottura, risparmio di materiali e costi, facile pulizia, e alta efficienza. Utilizzando questa attrezzatura, i produttori possono migliorare significativamente la consistenza del gusto delle loro patatine, ridurre gli sprechi di condimento, e migliorare l’efficienza della linea di produzione e la competitività del prodotto.

Se desideri saperne di più sulle specifiche del modello specifico, capacità produttiva, opzioni di personalizzazione, dimostrazioni video, o preventivi per questa macchina per il rivestimento di condimenti / aromi di patatine (struttura a botte ottagonale), vi preghiamo di contattarci on-line. Ti forniremo una consulenza tecnica precisa e soluzioni di selezione per aiutarti a ottimizzare la copertura dei sapori e la competitività sul mercato dei tuoi prodotti a base di patatine.