产品列表

工业水果和蔬菜洗涤线与内联脱水机器

产品详情:

| 发源地: | 河南华食品,中国 |

|---|---|

| 品牌: | 华食品 |

| 认证: | 国际标准化组织,CE,通标公司 |

| 型号: | HDF6000 |

工业果蔬清洗线及在线脱水机是一套集清洗、脱水于一体的自动化设备, 专为果蔬加工企业设计, 旨在高效、彻底地清洗各种水果和蔬菜. 它由提升输送带组成, 气泡清洁部分, 喷雾漂洗区和在线脱水模块. 整体采用食品级不锈钢材质,适用于中央厨房, 农产品加工厂, 酒店及大型食堂. 该设备可显着提高清洁效率, 降低劳动力成本, 并确保产品符合更高的卫生标准. 是现代食品加工生产线的重要组成部分.

蔬菜清洗线参数

| 胡萝卜清洗线总产量 500-1000 公斤 / H | ||

| 物品 | 力量 | 尺寸 |

| 泡泡清洗机 | 3.75千瓦/380伏/50赫兹 | 4000*1200*1300毫米 |

| 提升机 | 0.75千瓦/380伏/50赫兹 | 2000*1000*1900毫米 |

| 毛辊清洗机 | 2.0千瓦/380伏/50赫兹 | 2000*1000*1300毫米 |

| 振动机 | 1.5千瓦/380伏/50赫兹 | 1500*1000*1300毫米 |

| 空气干燥机 | 15千瓦/380伏/50赫兹 | 4000*1200*1400毫米 |

| 笔记: 这些参数为常规参数,可根据客户需求定制 | ||

果蔬清洗机工作原理

提升和喂料: 果蔬由输送机通过不锈钢网带引入清洗工段,保证物料在生产线上的连续流动.

泡泡滚滚 + 刷涂喷雾: 使用气泡发生器制造水下翻滚, 加高压水喷淋、刷洗去除污垢, 农业残留物和沉积物.

冲洗和过滤循环: 设置两级喷淋系统和循环过滤,实现二次清洗, 在节约用水、保护环境的同时.

脱水: 洗完后, 果蔬立即进入在线脱水模块 (如带式气刀或离心脱水) 快速去除表面水分,为后续切割或包装做好准备.

视频

果蔬清洗线工作原理

水果蔬菜清洗工艺

1.第一步,将需要清洗的蔬菜、水果放入泡泡清洗机中进行清洗;

2.第二步,用传送带将洗好的果蔬转移到毛滚筒清洗机进行二次清洗,确保蔬菜干净 100%;

3.第三步,通过振动筛去除果蔬中的部分水分;

4.第四步,将振动筛中的果蔬中的水分全部去除,进入空气干燥机;

5.第五步,将清洗干净的蔬果根据需要进行切割

最后, 根据您的需求, 你可以剪, 干燥, 冻结, 盒, ETC.

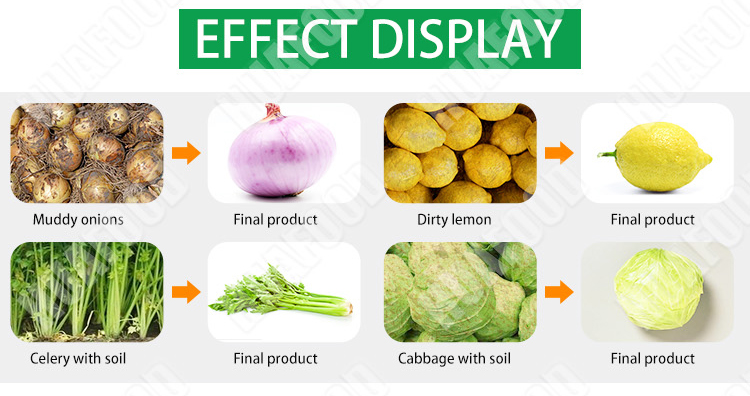

果蔬清洗线应用

我们专业生产各种果蔬生产线。这是一条完整的生产线, 适用于各种蔬菜和水果, 比如胡萝卜片, 红枣, 卷心菜, 洋葱, 柑橘, 牛油果, ETC.

适用场景: 超级市场, 餐馆, 食品加工厂, 冷冻植物, 干果加工产品.

蔬菜清洗线优点

高效节能: 泡沫 + 喷雾方式提高去污效率, 循环水系统可节省 80% 水的.

强大的加工能力: 适用范围广,产能大. 单机可处理数百至数千公斤/小时, 适用于各种规模的工厂.

易于操作, 安全卫生: 变频调速, 无噪音设计; 不锈钢网带可折叠/拆卸,方便清洁和维护.

水果清洗线特点

集成清洗系统: 集成输送, 泡沫洗涤, 喷雾漂洗和脱水, 专为自动化装配线设计.

可调模块: 传送带速度, 清洗时间和脱水强度可根据不同物料手动或PLC控制调节.

食品等级材料: 整机机身采用AISI材质 304 不锈钢, 符合国际食品安全卫生标准

结论

该工业果蔬清洗线与在线脱水机汇集了现代食品加工行业的精髓. 不仅在洗涤效率上具有明显优势, 水资源利用, 和操作简便性, 还提供从前端投料到后端脱水的一站式解决方案. 如果想提高车间自动化水平, 降低运营成本, 并确保产品安全和质量, 请立即在线留言👇获取详细设备参数, 定制解决方案和项目报价. 我们将有专业的工程师为您解答疑问并提供全方位支持!