产品列表

不锈钢去皮洋葱剥皮机去除皮肤

产品详情:

| 发源地: | 河南华食品, 中国 |

|---|---|

| 品牌: | 华食品 |

| 认证: | 国际标准化组织,CE,通标公司 |

| 型号: | 定制化 |

| 应用 | 广泛应用于蔬菜加工行业. |

介绍

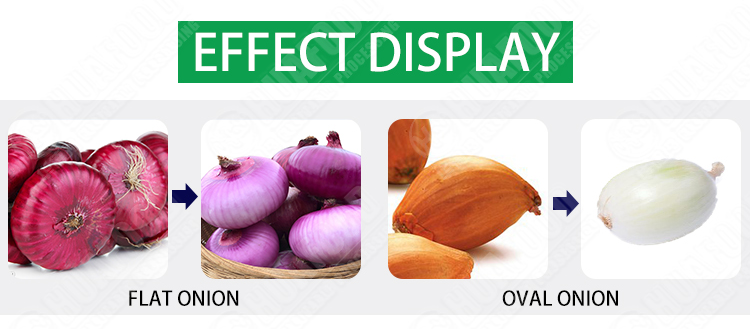

不锈钢洋葱剥皮机是一种自动化的溶液,该溶液设计可从洋葱中剥离第一和第二肤,而不会损坏灯泡。它可容纳洋葱从 45 MM TO 105 毫米直径并处理到 3,000 每小时单位, 大量超过手动剥离方法.

|

模型

|

HYC-500

|

|

上传中

|

3 腰带

|

|

尺寸

|

2150*1150*2000毫米

|

|

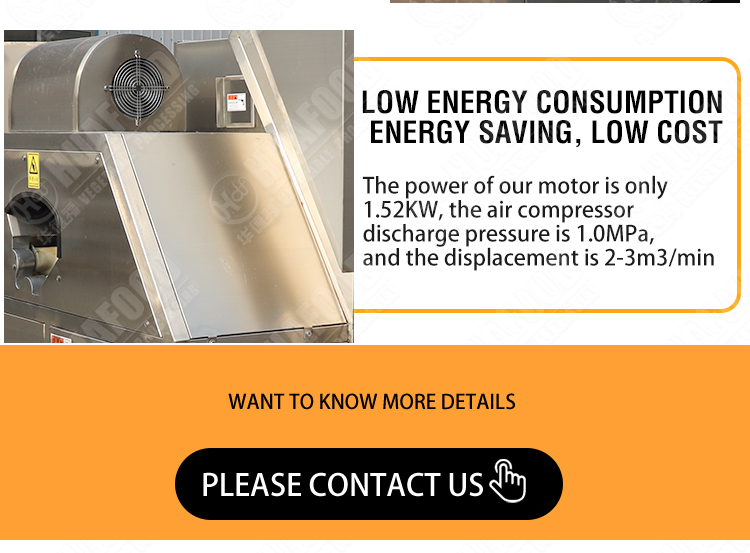

电源

|

380V, 50赫兹,3PH值

|

|

气源

|

1.0MPa以上

|

|

力量

|

1.52千瓦

|

|

输出

|

1500-2000公斤/小时

|

|

重量

|

320公斤

|

视频

工作准则

洋葱脱皮机采用去皮不切根的加工方式. 这样, 去皮的洋葱皮体积小, 产量高, 且室内干净卫生无污染. 要求任何状态的洋葱都能一次性去皮并去除干净. 该机已广泛应用于蔬菜加工行业.

特征

1. 满的 304 食品级不锈钢建筑

所有接触部件 - 包括鼓, 刀片, 和框架 - 由SUS304不锈钢制成, 确保耐腐蚀和卫生操作.

2. 气动/空气喷射系统

利用通过多端口剥皮车轮或气动辊的压缩空气轻轻去除外层而不会造成摩擦损坏, 保持洋葱完整性 .

3. 可变速度 & 深度控制

配备频率逆变器, 操作员可以微调剥离速度 (500–1,500 rpm) 并调节气压 (0.8–1.0 MPA) 适合干洋葱或湿洋葱,并从中控制果皮深度 0.2 MM TO 0.5 毫米 .

4. 连续传送带饲料

一条食品级皮带将洋葱通过剥离室以光滑, 不间断的流程, 使能力来自 600 kg/h到 2,500 kg/h取决于模型 .

5. 快速释放模块化刀片 & 鼓

模块化剥离鼓和刀片组件无需工具即可进出, 促进批次之间的快速转换并简化卫生程序 ;

优势

①洋葱不需要分级, 无论大小都可以剥皮, 潮湿和干燥. .

②蒙皮自动化, 一次性自动完成、干净剥皮.

③ “皮层控制器” 可自由控制剥离层深度, 只需要剥一层皮或者剥第二层皮就可以实现.

④机器采用不锈钢材质 304, 寿命长、防锈能力强.

好处

劳动节省: 每班替换8-10名工人, 节省高达5,000美元/月的人工成本;

一致的产品质量: 均匀的剥离增强了下游切片, dit, 和脱水过程, 提高整体产量和外观;

减少停机时间: 模块化零件和气动系统最大程度地减少堵塞和机械磨损, 交付 16 可靠操作的时间/天;

增强食品安全: 带有快速释放组件的闭环不锈钢设计可彻底CIP (清洁) 打扫, 会议CE, FDA, 和ISO 22000 标准;

不锈钢去皮洋葱去皮机去除皮肤, 节能气动剥离, 并将用户友好的控件转变为现代食品处理器的多合一解决方案. 它提供了无与伦比的效率, 质量一致性, 和卫生业务 - 餐馆的理想, 食堂, 脱水食品制造商, 和大规模餐饮业.

准备提升洋葱加工线?

👉 给我们一个在线查询 今天的详细规格, 自定义配置, 和有竞争力的报价!