产品列表

可食用油过滤的连续真空棕榈油滤清器

产品详情:

| 发源地: | 郑州,河南,中国 |

|---|---|

| 品牌: | 华食品 |

| 认证: | 国际标准化组织,CE,通标公司 |

| 型号: | HQC-612D |

| 过滤材料: | 用于烹饪油炸, 椰子, 花生, 棕榈, 大豆, 芝麻, 向日葵, 脚轮, 烹饪, 橄榄, 芥末 |

|---|---|

| 过滤深度: | 5-层过滤 |

| 原则: | 真空离心 |

| 滤镜效果: | 99% |

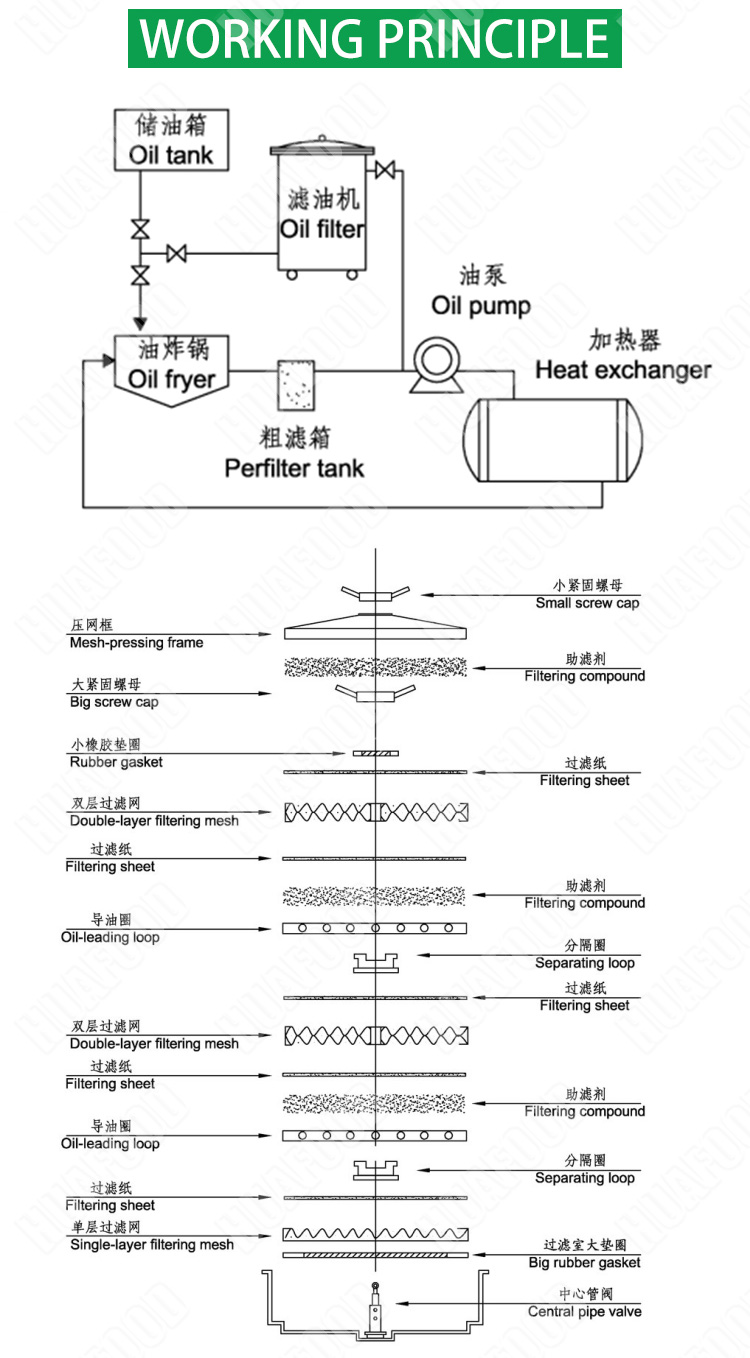

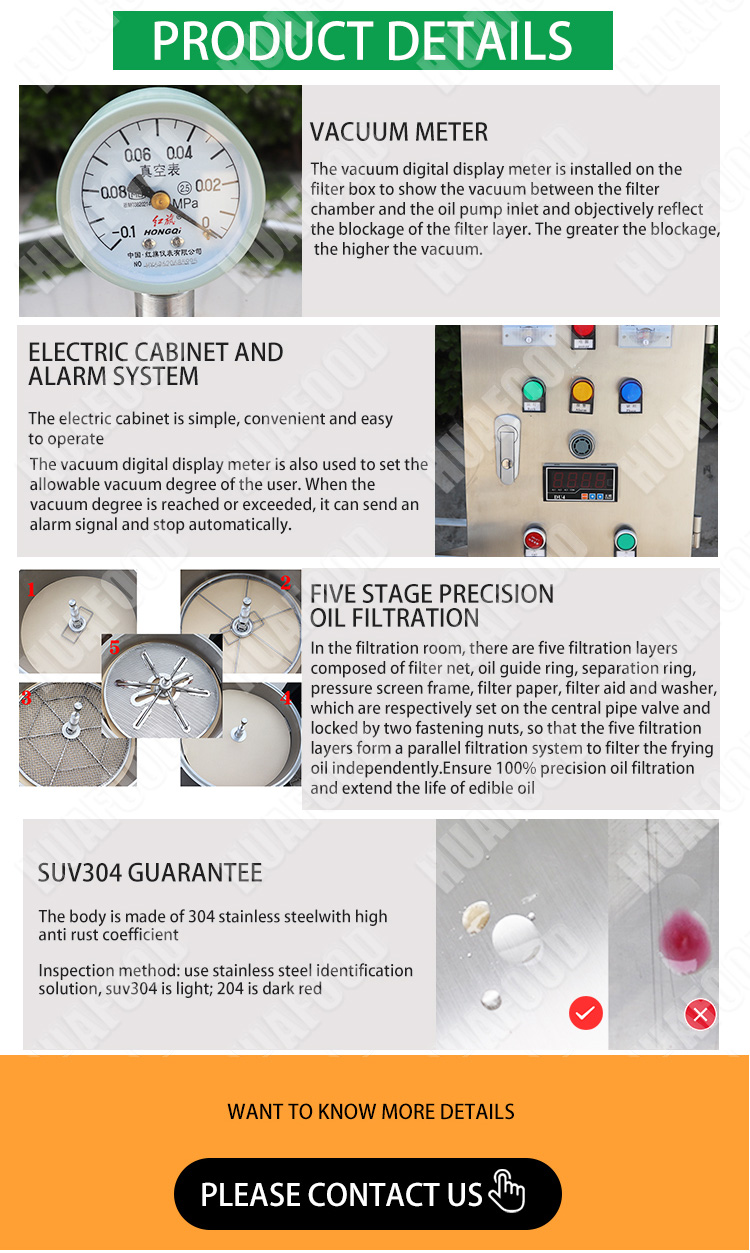

油炸冷却食用油过滤连续式真空棕榈油过滤机是针对高温油炸冷却后的棕榈油及油品而设计的连续式真空过滤设备. 集真空脱气、脱水于一体, 喷雾雾化, 五级精密过滤及冷却功能. 可连续去除水分, 气体, 在不中断生产的情况下去除油中的碳尘和细小悬浮物, 有效提高清晰度, 棕榈油的颜色和味道, 满足高品质食用油生产的严格要求.

视频

风淋室如何工作 & 参数

石油开采和加热: 该设备从油炸锅或冷却罐中抽取高温油并加热到合适的温度,使油中的水和气体汽化.

真空喷雾脱水脱气: 在真空环境下, 油通过喷雾系统雾化, 使水蒸气迅速汽化并抽至冷凝系统.

多级过滤,减少杂质: 油首先收集大颗粒 (例如面团和碳片) 经过粗过滤, 然后去除颗粒, 色素和异味通过精细过滤和吸附介质实现高精度净化.

冷却及循环: 过滤后的油经冷却装置冷却至目标温度后, 循环回油罐或储油系统,实现连续生产.

食用油过滤机参数

| 模型 | HLY63-A | HLY125-A | HLY125-A |

| 过滤层数 | 五段式 | 五段式 | 三段式 |

| 滤油量 | 30升/分钟 | 80升/分钟 | 80升/分钟 |

| 过滤面积 | 1.03平方米 | 2.0米2 | 1.2米2 |

| 出口压力 | 0.5兆帕 | 0.5兆帕 | 0.5兆帕 |

| 力量 | 1.5千瓦 | 3.0千瓦 | 3.0千瓦 |

| 重量 | 180公斤 | 550公斤 | 550公斤 |

| 电压 | 380伏/50赫兹 | 380伏/50赫兹 | 380伏/50赫兹 |

| 进油管直径 | 1.0 英寸 | 2.0 英寸 | 2.0 英寸 |

| 出油管直径 | 1.0 英寸 | 1.5 英寸 | 1.5 英寸 |

| 机器尺寸 | 850*850*1100毫米 | 1100*1000*1300毫米 | 1100*1000*1300毫米 |

应用

油炸机食用油过滤机

油炸机食用油过滤机

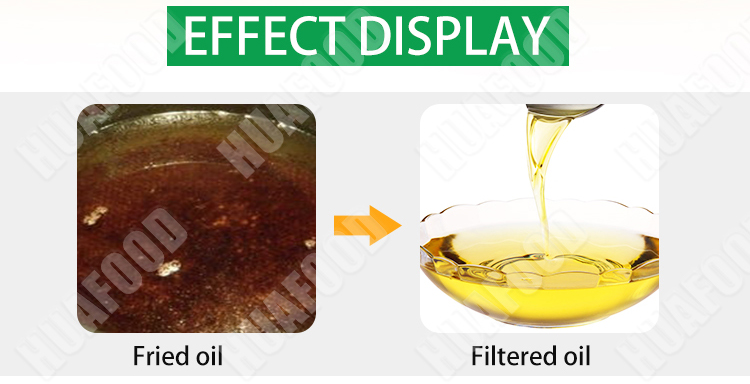

据我们所知, 食品生产过程中会有较长时间的煎炸油 , 并且质量会逐渐下降. 油炸产品呈黑色, 油的气味, 含油量高, 酸价、过氧化值超标, 烟等. 极大地影响顾客对食物的认知. 也带来食品卫生安全问题. 所以, 煎炸油使用一段时间后必须更换, 然而, 经常更换煎炸油会使生产成本更高. 使用HFD煎炸油过滤设备就能解决以上问题. 煎炸油过滤机可以延长油的寿命, 节省石油成本.

特征

滤饼含油量控制

电阻传感器精度 ±0.5%

动态调整氮气吹扫持续时间

三级真空梯度系统

真空度自适应调节 (-0.08 ~ -0.092 兆帕)

匹配80-95℃粘度变化 (45→18 厘泊)

氮气惰化密封舱

实时监测氧气含量 <50 百万分之一

保护油酸等不饱和脂肪酸 (39-45%)

抗剪切钛合金过滤叶片

表面硬化 (38 HRC) 抵抗棕榈油残留磨料颗粒 (>80微米二氧化硅)

无滤布设计消除了 CPO 过滤中的撕裂风险

好处

– 减少油的氧化和酸败, 改善风味, 色彩与消费者体验;

– 连续运行自动化程度高, 减少人工操作成本;

– 显着降低棕榈油中的水分和游离气体, 延长储存和使用寿命;

结论

“连续真空棕榈油过滤机用于油炸冷却食用油过滤” 集成真空喷雾脱水, 精密五级过滤和油冷却,专门满足棕榈油及其特性在煎炸和冷却过程中的要求. 不仅提高了过滤精度, 而且还大大延长了油品的生命周期, 显着降低更换成本, 并帮助油厂和大型厨房实现高效, 聪明的, 节能更环保的油品管理.

立即在线留言获取详细技术参数, 容量选择, 设备自动化程度及报价方案. 我们的专业工程团队将为您提供定制咨询和项目支持 24 小时!

700-500-6.jpg)

700-500-5.jpg)

700-500-4-1.jpg)