产品列表

小型通心粉生产线,用于挤出面食制作

产品详情:

| 发源地: | 河南华食品, 中国 |

|---|---|

| 品牌: | 华食品 |

| 认证: | 国际标准化组织,CE,通标公司 |

| 型号: | 定制化 |

| 应用: | 该生产线可用于生产颗粒, 零食, 通过调整挤出机的型号来生产玉米片 |

介绍

Spaghetti Production Line generally uses special flour (usually starch-rich grains or coarsely ground wheat flour) 作为原料. Its production process includes mixing, extrusion maturation, molding, cutting, drying, ETC. The equipment is all automatically controlled to achieve fully automatic assembly line production. Its products include extruded noodles such as knife-cut wide noodles (an upgraded product of instant noodles) and various shapes of pasta (such as hollow round tubes, shells, rice grains, ETC。); the noodle products produced by this production line have a stronger taste and are more resistant to cooking than traditional noodles and instant noodles; and the texture is closer to handmade noodle products, which are deeply recognized by consumers.

Spaghetti Manufacturing Process / How Spaghetti Is Produced

A Spaghetti Production Line is a series of interconnected machines that automates pasta manufacturing from raw flour to packaged product. It begins by mixing durum wheat semolina (or special flour formulations) with water—and optionally eggs—into a homogeneous dough. The dough is then fed into an extruder where high-pressure screws shape it through stainless-steel dies into long strands or short-cut forms like macaroni.A Spaghetti Production Line is a series of interconnected machines that automates pasta manufacturing from raw flour to packaged product. It begins by mixing durum wheat semolina (or special flour formulations) with water—and optionally eggs—into a homogeneous dough. The dough is then fed into an extruder where high-pressure screws shape it through stainless-steel dies into long strands or short-cut forms like macaroni.

The typical workflow of the line is:

Pasta Production Line 优势

采用马铃薯淀粉, 玉米淀粉, 木薯淀粉, 面粉, 以玉米粉等为原料

2). 产品:

该生产线可用于生产颗粒, 零食, 通过调整挤出机的型号来生产玉米片;

3). 容量: 100-250公斤/小时

4). 流程图:

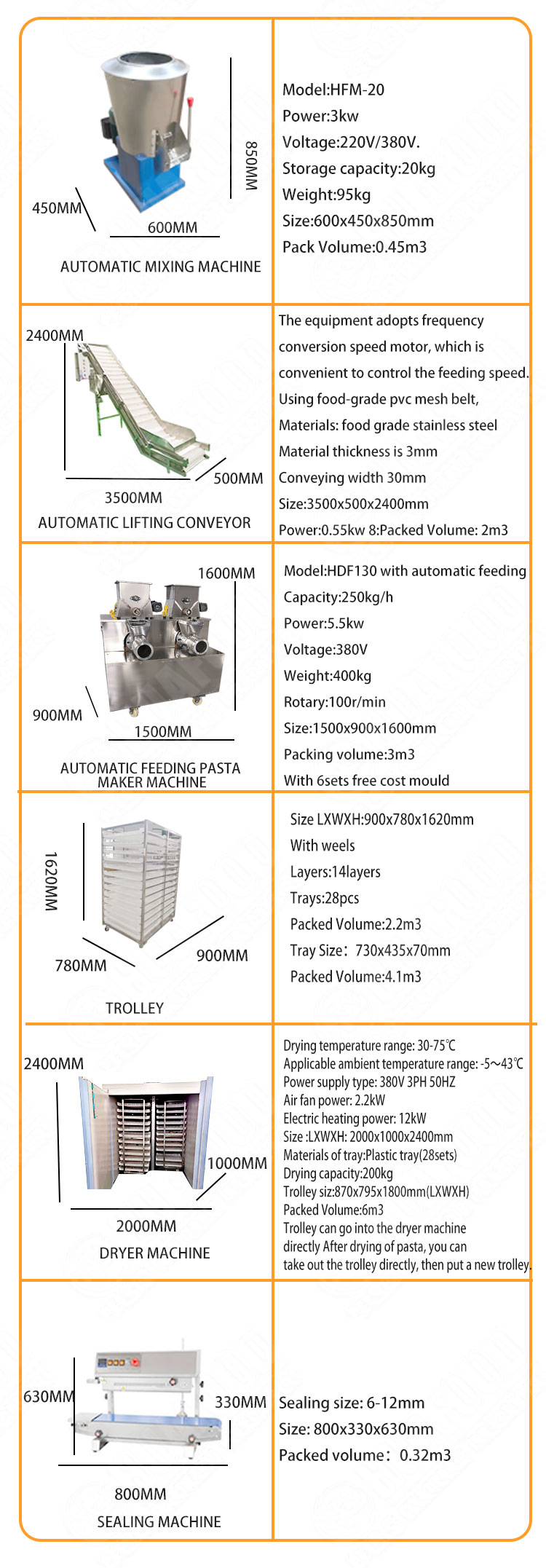

搅拌系统—-升降系统—-挤出系统—-切割系统—-干燥系统—-包装系统

5). 中国电压: 三个阶段: 380伏/50赫兹, 单相: 220伏/50赫兹, we can make it according to customers’ Local voltage according to different countries

6). 机器材料:

所有机器均由不锈钢制成

Macaroni Production Line Features

Compact Design for capacities from 50–200 kg/h, fitting limited floor space;

PLC Automation ensures stable operation, easy recipe switching, and remote diagnostics;

Quick-Change Dies allow shape transitions in under 30 分钟, reducing downtime;

Food-Grade Construction with 304 stainless steel for all contact parts, facilitating rapid cleaning and hygiene compliance;

Macaroni Making Machine Benefits

Cost Savings: Reduced labor and waste translate to faster ROI and lower per-unit cost;

Enhanced Product Variety: Rapid mold swaps enable production of multiple pasta shapes to meet diverse market demands;

Scalable Output: Capacity can be increased by adding parallel lines or upgrading to higher-capacity extruders without major footprint changes;

Evidence

Industry Adoption: Over 100 small-scale installations worldwide report uptime exceeding 95% and product consistency praised by chefs and artisan brands;

Customer Testimonials: “Our new small macaroni line doubled output and cut labor by 40%—quality rivals large-scale factories!”

结论 & Call to Action

A Small Macaroni Production Line offers compact automation, flexible shape capabilities, and proven cost-efficiency—empowering small businesses and specialty producers to compete with larger manufacturers. Ready to transform your pasta production? Leave us an online message today to discuss customization options, detailed quotes, and delivery timelines!