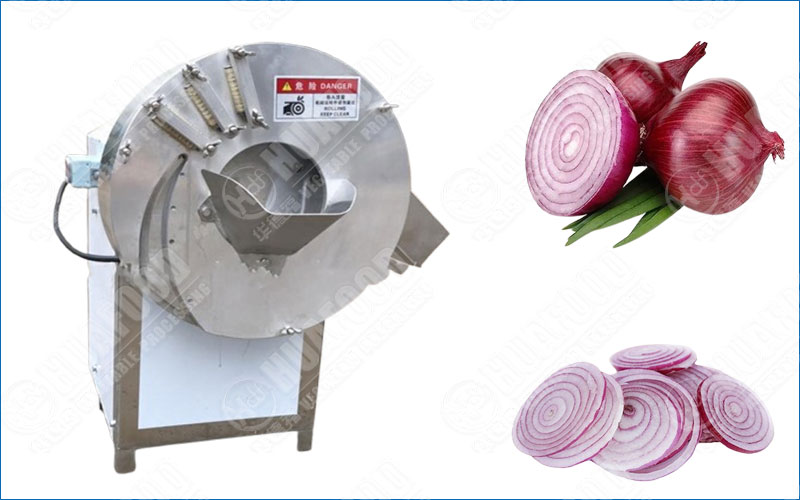

آلة تقطيع البصل عالية الكفاءة الكهربائية للبيع

Our Onion Slicing Machine Electric For Sale is a state-of-the-art onion processing solution specially designed for medium to large scale food operations. This electric onion slicer offers rapid, consistent slicing of fresh onions with minimal labor. Its efficiency, تصميم صحي, and ease of operation make it ideal for food factories, catering services, frozen food processors, spice factory, snack producers, and restaurants that demand high throughput with precise onion slices. Whether you need thin rings or thicker slices, this machine aims to deliver uniform, clean cuts while maintaining onion integrity.

Onion Slicer Machine Working Principle

The electric onion slicer working principle can be divided into the following main steps:

Feeding and Positioning

After being cleaned and peeled, fresh onions are fed into the slicing area through the feed inlet. The machine is typically equipped with a feed guide or push mechanism to ensure that the onions are cut in the correct position.

(This feeding and positioning method is common in similar equipment designs.)

Rotary Blade Cutting

Inside the blade chamber, a high-speed rotating slicing blade (or multiple blades) cuts the onions. The blade rotates at a preset speed, creating continuous slices under the action of the blade. The slice thickness can be adjusted by controlling the relative speed and distance between the blade and the onion.

Guidance and Discharge

The sliced onions slide out of the cutting area by gravity or auxiliary guides, falling onto a receiving trough or conveyor belt for further processing (such as dehydration, تجفيف, والتعبئة والتغليف). Some machines may also be equipped with air blowing or shaking mechanisms to prevent the onion slices from sticking.

By precisely controlling parameters such as tool geometry, rotation speed, and feed rate, this machine can consistently slice onions into slices of uniform thickness while minimizing edge damage.

Onion Slicing Machine Advantages

Uniform & Precise Slices — Slices are uniform, with smooth edges and no breakage, improving subsequent product quality and consistency.

Low Labor & Fast Throughput — High automation reduces manual labor; high-efficiency cutting significantly increases production.

Easy Cleaning & Maintenance — Removable blades and cover facilitate daily cleaning and maintenance, extending equipment life.

Durability & Hygienic Safety — All food-grade stainless steel construction and wear-resistant blades resist corrosion and oxidation, and comply with food equipment hygiene regulations.

Onion Slicer Features

Adjustable Slice Thickness — Blade spacing can be adjusted, allowing slice thickness to be adjusted between 1.5 و 6 مم (or customizable range) to meet diverse needs.

High-Speed Rotating Blades — High-speed rotating blades ensure high rotation speed, stable cutting, and high productivity.

Food-Grade Stainless Steel Construction — The machine body and key components are constructed of 304 stainless steel or high-quality food-grade materials, meeting hygienic standards, مقاومة التآكل, وسهولة التنظيف.

مدمج & Ergonomic Design — The compact structure occupies a small footprint, making it easy to install and operate. The design is well-designed and the user interface is user-friendly.

Onion Slicing Machine Benefits

Reduced Waste/Stopage – Precise knife control and gentle cutting reduce debris and breakage, improving raw material utilization.

Speedier Production – Highly efficient automated cutting shortens processing cycles, enabling quicker response to market order demands.

يقلل من تكاليف العمالة – Traditional manual onion chopping is time-consuming and labor-intensive, but using this machine significantly reduces labor requirements and errors.

Improves Product Consistency – The thickness and shape of sliced onions are consistent, facilitating quality control during subsequent processing (such as dehydration, القلي, والتعبئة والتغليف).

شهادة

Success Stories / Customer Feedback — Multiple onion processing plants have doubled their production capacity and reduced labor by adopting similar slicing equipment.

Quality Standard Certification — The equipment can be designed to comply with food equipment certification standards such as CE, ايزو, and SGS, providing confidence in hygiene and safety.

Test Data / Technical Parameters — Depending on the specific specifications, the equipment can achieve a production capacity of hundreds to thousands of kilograms per hour (depending on the model).

Durable Materials and Lifespan — Utilizing high-quality stainless steel, premium blades, and an easily disassembled structure, it ensures long-term, stable operation with proper maintenance.

خاتمة

إجمالي, the High Efficiency Onion Slicing Machine Electric is a high-performance slicing machine designed specifically for the onion processing industry. It combines adjustable slice thickness, high-speed blades, stainless steel construction, and a compact design, offering significant advantages in automation, production efficiency, product consistency, and equipment durability. For onion processing plants, مصانع الأغذية المجمدة, quick-frozen vegetable plants, or dehydrated onion slice production lines, it offers practical value by saving labor, الحفاظ على جودة متسقة, and increasing production capacity.

If you are interested in this machine’s specifications, models, يقتبس, or customization options, please leave a message online on this page or contact us. We will provide you with more detailed technical information, performance demonstration videos, والحلول المخصصة. We look forward to working with you!