LISTA DE PRODUCTOS

Máquina continua del filtro de aceite de palma del vacío para la filtración del aceite comestible

Detalles de producto:

| Lugar de origen: | Zhengzhou,Henán,Porcelana |

|---|---|

| Nombre de la marca: | HUAFOOD |

| Certificación: | YO ASI,CE,SGS |

| Número de modelo: | HQC-612D |

| Material filtrante: | freír usado para cocinar, Coco, maní, palmera, haba de soja, sésamo, girasol, castor, cocinando, aceituna, mostaza |

|---|---|

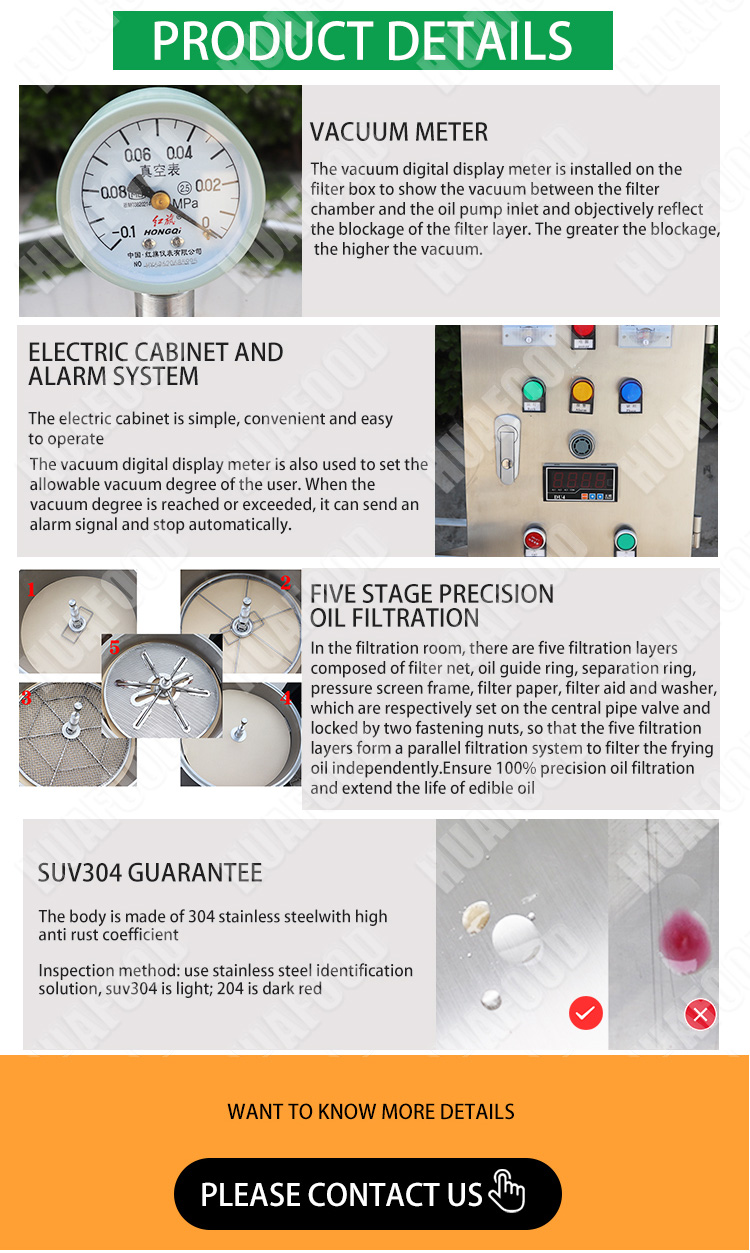

| Profundidad del filtro: | 5-filtración por capas |

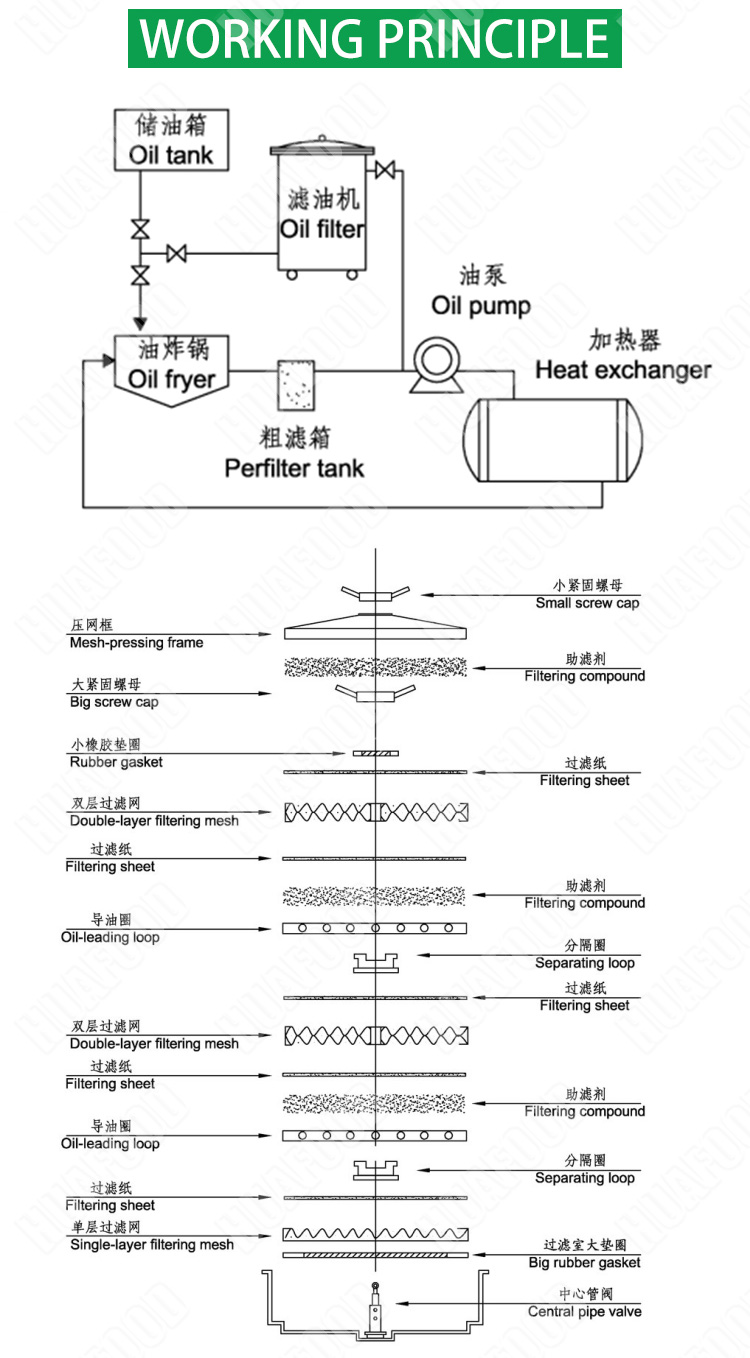

| Principio: | centrífuga de vacío |

| Efecto de filtro: | 99% |

Máquina de filtrado continuo de aceite de palma al vacío para enfriamiento frito La filtración de aceite comestible es un equipo de filtración al vacío continuo diseñado para aceite de palma y productos derivados del aceite después de freír y enfriar a alta temperatura.. Integra desgasificación y deshidratación al vacío., atomización por pulverización, Funciones de filtración y enfriamiento de precisión de cinco etapas.. Puede eliminar continuamente la humedad., gas, polvo de carbón y partículas finas en suspensión en el aceite sin interrumpir la producción, mejorando efectivamente la claridad, Color y sabor del aceite de palma., y cumplir con los estrictos requisitos de la producción de aceite comestible de alta calidad..

Video

¿Cómo funcionan las duchas de aire? & Parámetros

Extracción y calefacción de petróleo.: El equipo extrae aceite a alta temperatura de la freidora o del tanque de enfriamiento y lo calienta a una temperatura adecuada para vaporizar el agua y el gas en el aceite..

Deshidratación y desgasificación por pulverización al vacío.: En un ambiente de vacío, El aceite se atomiza mediante un sistema de pulverización., para que el vapor de agua se vaporice rápidamente y se extraiga al sistema de condensación.

Filtración multietapa y reducción de impurezas.: El aceite primero recoge partículas grandes. (como masa y virutas de carbono) mediante filtración gruesa, y luego elimina las partículas, pigmentos y olores a través de medios de filtración y adsorción finos para lograr una purificación de alta precisión.

Enfriamiento y circulación: Después de que el aceite filtrado se enfríe a la temperatura objetivo a través de la unidad de enfriamiento, Se hace circular de regreso al tanque de aceite o al sistema de almacenamiento de aceite para lograr una producción continua..

Parámetros de la máquina de filtrado de aceite de cocina

| Modelo | HLY63-A | HLY125-A | HLY125-A |

| Número de capas de filtro | Tipo de cinco segmentos | Tipo de cinco segmentos | tipo de tres segmentos |

| Cantidad de filtrado de aceite | 30l/min | 80l/min | 80l/min |

| área de filtro | 1.03m2 | 2.0metro2 | 1.2metro2 |

| presión de salida | 0.5MPa | 0.5MPa | 0.5MPa |

| Fuerza | 1.5kilovatios | 3.0kilovatios | 3.0kilovatios |

| Peso | 180kg | 550kg | 550kg |

| Voltaje | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Diámetro del tubo de entrada de aceite | 1.0 pulgadas | 2.0 pulgadas | 2.0 pulgadas |

| Diámetro del tubo de salida de aceite | 1.0 pulgadas | 1.5 pulgadas | 1.5 pulgadas |

| Tamaño de la máquina | 850*850*1100milímetros | 1100*1000*1300milímetros | 1100*1000*1300milímetros |

Solicitud

Máquina de filtro de aceite de cocina para freidora

Máquina de filtro de aceite de cocina para freidora

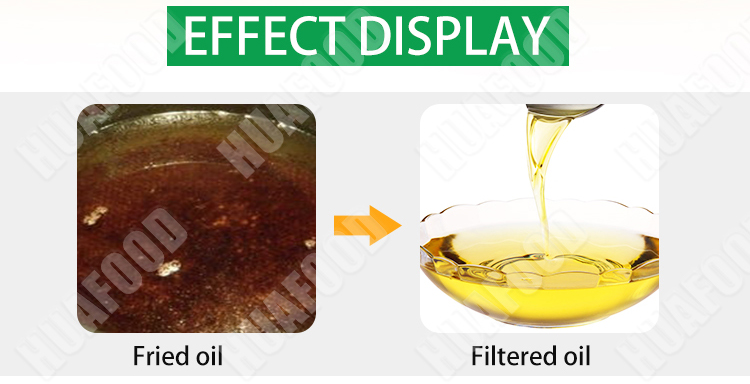

Como la conocemos, El proceso de producción de alimentos tendrá un largo tiempo de aceite para freír. , y la calidad disminuirá gradualmente. Los productos fritos aparecen negros., el olor a aceite, alto contenido de aceite, Se excede el índice de acidez y el índice de peróxido., fumar y así sucesivamente. Afecta en gran medida la percepción que el cliente tiene de la comida.. Y también trae problemas de higiene y seguridad alimentaria.. Por lo tanto, El aceite para freír debe reemplazarse después de un período de uso., sin embargo, A menudo, reemplazar el aceite para freír aumentará los costos de producción.. El uso de equipos de filtración de aceite de fritura HFD podrá resolver los problemas anteriores.. La máquina de filtrado de aceite para freír puede prolongar la vida útil del aceite, ahorrando el costo del petróleo.

Características

Control del contenido de aceite de la torta de filtración

Precisión del sensor de resistencia ±0,5%

Ajustar dinámicamente la duración de la purga de nitrógeno

Sistema de gradiente de vacío de tres etapas.

Ajuste adaptativo del grado de vacío. (-0.08 ~ -0.092 MPa)

Cambios de viscosidad coincidentes a 80-95 ℃ (45→18 cP)

Cabina sellada con inertización de nitrógeno

Monitoreo en tiempo real del contenido de oxígeno. <50 ppm

Protección de ácidos grasos insaturados como el ácido oleico. (39-45%)

Cuchillas de filtro de aleación de titanio resistentes al corte

Endurecimiento superficial (38 CDH) para resistir las partículas abrasivas de los residuos de aceite de palma (>80µm de sílice)

El diseño sin tela filtrante elimina el riesgo de desgarro en la filtración de CPO

Beneficios

– Reducir la oxidación y rancidez del aceite., mejorar el sabor, color y experiencia del consumidor;

– Alto grado de automatización en funcionamiento continuo, reduciendo los costos de operación manual;

– Reducir significativamente la humedad y el gas libre en el aceite de palma., Ampliación de la vida útil y de almacenamiento.;

Conclusión

“Máquina continua del filtro de aceite de palma del vacío para la filtración de enfriamiento frita del aceite de mesa” integra deshidratación por aspersión al vacío, Filtración precisa de cinco etapas y enfriamiento del aceite para cumplir específicamente con los requisitos del aceite de palma y sus características durante la fritura y el enfriamiento.. No solo mejora la precisión de la filtración, pero también extiende en gran medida el ciclo de vida del aceite., reduce significativamente los costos de reemplazo, y ayuda a las almazaras y a las grandes cocinas a lograr una eficiencia, inteligente, Gestión del aceite que ahorra energía y es más respetuosa con el medio ambiente..

Deje un mensaje en línea ahora para obtener parámetros técnicos detallados, selección de capacidad, Grado de automatización y soluciones de cotización de los equipos.. Nuestro equipo de ingeniería profesional le brindará consultas personalizadas y soporte para proyectos dentro de 24 horas!

700-500-6.jpg)

700-500-5.jpg)

700-500-4-1.jpg)