LISTA DE PRODUCTOS

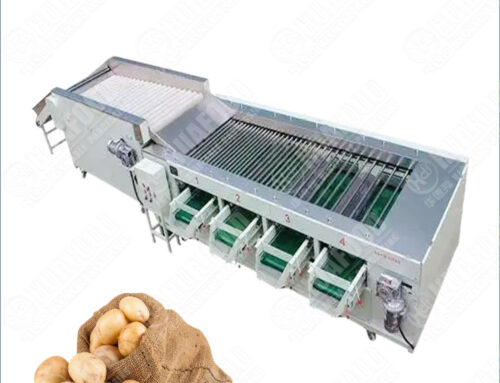

Máquina automática de equipos de procesamiento de pasta de papa

Detalles de producto:

| Lugar de origen: | Henan Huafood, Porcelana |

|---|---|

| Nombre de la marca: | HUAFOOD |

| Certificación: | YO ASI,CE,SGS |

| Número de modelo: | personalizado |

Revolutionize potato paste production with our Automatic Potato Paste Making Processing Equipment Machine – an integrated industrial system engineered specifically to transform raw potatoes into ultra-smooth paste/starch slurry at commercial scale. By solving core challenges of enzymatic browning control, starch loss minimization, and texture homogenization, this turnkey solution ensures consistent output for applications like potato starch, gnocchi, aperitivos, and gluten-free baking ingredients.

How To Make Potato Paste

Raw Potato Handling → Automatic Washing & Peeling → Steam Blanching → Grinding & Homogenization → Vacuum Deaeration → Pasteurization → Aseptic Filling

Key Component Descriptions

-

Brush Washer-Peeler → Removes 99% soil/debris while preserving starch-rich flesh

-

Steam Blancher → Inactivates polyphenol oxidase to prevent browning (critical for potato paste whiteness)

-

Colloid Mill System → Ultra-fine grinding (50-100μm) breaks down pectin cells without gelatinizing starch

-

Vacuum Deaerator → Eliminates oxygen to extend shelf-life and maintain creamy texture

-

HTST Pasteurizer → Preserves viscosity at 95°C/30s with ±1°C accuracy

-

Automated Filling Module → Seamless packaging integration with CIP sanitation

Video

Potato Paste Making Machine Advantages

✅ 98% Starch Retention vs. 82-88% in traditional milling

✅ Zero Discoloration : Maintains natural white/cream color for premium products

✅ 50% Energy Reduction : Regenerative heat exchange in blanching/pasteurization stages

✅ 60 min Quick-Changeover : Modular design adapts to sweet potato/taro processing

Potato Paste Processing Machine Features

Potato Paste Machine Benefits

💡 Higher Product Quality : Liso, stable paste ideal for freeze-drying/extrusion

💡 Extended Shelf-Life : 12-month ambient stability without preservatives

💡 Reduced Waste Cost : <0.5% product loss vs. 5-7% in batch systems

💡 Faster ROI : Processes 1 ton potatoes/hour with 2 operators

Conclusión

This end-to-end Automatic Potato Paste Making Processing Equipment Machine delivers unparalleled efficiency in converting raw tubers into high-value paste – solving the color instability, texture variance, and starch waste that plague manual operations.

Unlock Your Potato Processing Potential Today!

➤ Contact Us For:

Free Process Flow Diagram customized for your raw material

On-Site Trial using your local potato varieties

Turnkey Installation with operator training