DAFTAR PRODUK

HDFW-6E High efficiency vegetable washing machine leeks green onions cleaning machine

Rincian Produk:

| Tempat asal: | Zhengzhou,Henan,Cina |

|---|---|

| Nama merk: | HUAFOOD |

| Sertifikasi: | ISO,CE,SGS |

| Nomor model: | HDFW-6E |

Video

Parameter

This is a complete processing line, suitable for various types of vegetables, such as carrot, kentang, kubis, Bawang, dll..

Skenario yang berlaku: supermarket, restoran, pabrik pengolahan makanan, tanaman beku, dried fruit processing plants,snak processing factory

| Total output dari jalur pencucian wortel 500-1000 kg / H | ||

| Barang | Kekuatan | Ukuran |

| Mesin Cuci Gelembung | 3.75kw/380v/50Hz | 4000*1200*1300mm |

| mesin pengangkat | 0.75kw/380v/50Hz | 2000*1000*1900mm |

| Mesin pembersih rol rambut | 2.0kw/380v/50Hz | 2000*1000*1300mm |

| mesin bergetar | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| mesin pengering udara | 15kw/380v/50Hz | 4000*1200*1400mm |

| Catatan: Parameter ini bersifat konvensional dan dapat disesuaikan dengan kebutuhan pelanggan | ||

.

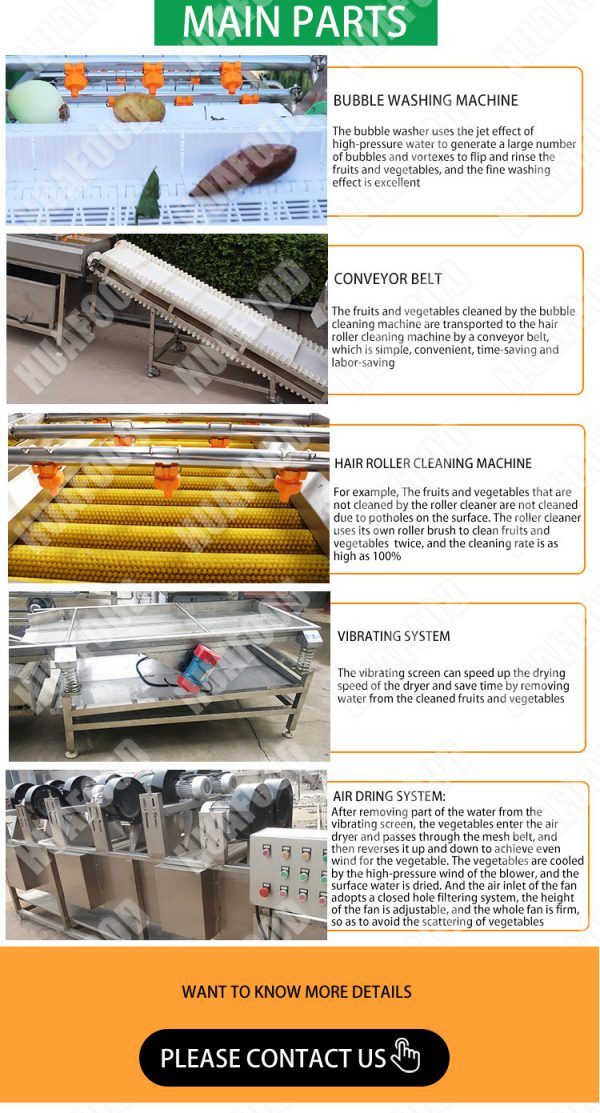

Prinsip bekerja

prosedur

1.Langkah pertama adalah memasukkan sayuran dan buah-buahan yang perlu dibersihkan ke dalam mesin cuci bubble untuk dibersihkan;

2.langkah kedua adalah menggunakan ban berjalan untuk memindahkan buah dan sayuran yang sudah dicuci ke mesin cuci roller rambut untuk pembersihan sekunder guna memastikan sayuran bersih. 100%;

3.langkah ketiga adalah menghilangkan sebagian air dari buah dan sayuran melalui layar getar;

- langkah keempat adalah membuang semua air dari buah dan sayuran dari layar getar ke dalam pengering udara;

5.langkah kelima potong buah dan sayur yang sudah dibersihkan sesuai kebutuhan

Akhirnya, sesuai dengan kebutuhan Anda, kamu bisa memotong, kering, membekukan, mengemas, dll..

Vegetable processing machinery

Prestasi

1. The equipment is cleaned in two stages before and after the two stages. The internal circulating water is cleaned at all levels, and the spray rack is connected to the tap water for secondary cleaning.

2. The spray water pressure is adjustable, and the bubbling volume is adjustable.

3. sterilisasi UV, ozone sterilization

4. Both sides of the baffle 70mm, conveyor belt material POM, kecepatan yang dapat disesuaikan, with the inverter. The cleaning time depends on the actual speed.