ELENCO PRODOTTI

Linea di produzione di produzione automatica di patatine fritte francese

Dettagli del prodotto:

| Luogo d'origine: | Henan Huafood,Cina |

|---|---|

| Marchio: | FUFOOD |

| Certificazione: | ISO,CE,SGS |

| Numero di modello: | HDF10T |

Pagamento & Termini di spedizione:

| Quantità di ordine minimo: | 1imposta |

|---|---|

| Prezzo: | USD21350-30000 |

| dettagli sul confezionamento: | Imballaggio standard in legno O pacchetto nudo in container da 20 piedi |

| Tempi di consegna: | 1giorni |

| Termini di pagamento: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Capacità di fornitura: | 15imposta 1 giorno |

IL Linea di produzione di produzione automatica di patatine fritte francese è un avanzato, Soluzione completamente automatizzata progettata per produrre in modo efficiente patatine fritte francesi di alta qualità per l'industria alimentare congelata e i settori di fast food.

Dall'assunzione di patate crude alla confezione finale, Questa linea di lavorazione è progettata per semplificare ogni fase della produzione di patatine francese, garantendo una consistenza perfetta, forma uniforme, colore coerente, e una durata di conservazione estesa. Sia che tu stia creando un nuovo impianto di elaborazione delle patatine francese o aggiornando le tue operazioni attuali, Questa linea di produzione offre una soluzione scalabile e affidabile su misura per soddisfare le esigenze dei consumatori moderni per croccanti, d'oro, e deliziose patatine fritte.

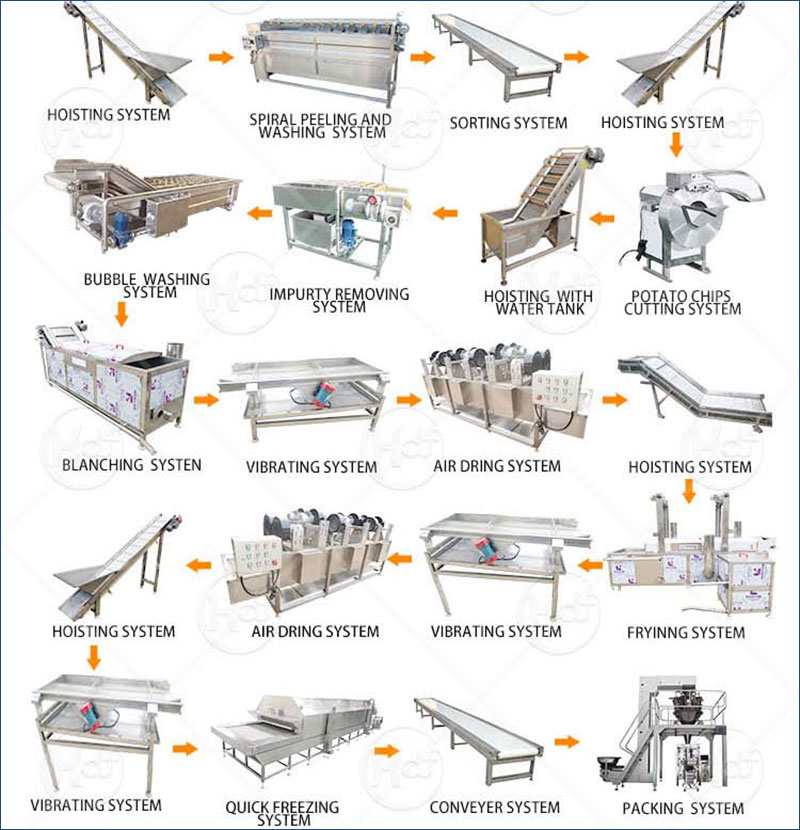

Processo di produzione di produzione di patatine francese

Lavaggio delle patate & peeling → ordinamento → taglio → risciacquo → sbiancamento → disidratazione → frittura → deoiling → congelamento → imballaggio

1️⃣ lavaggio delle patate & Macchina per peeling

Rimuove automaticamente lo sporco, impurità, e pelli di patate per prepararsi pulito, patate pronte per procedere.

2️⃣ Trasportatore di smistamento

Sistema di smistamento manuale o ottico per rimuovere le patate difettose e garantire l'uniformità delle dimensioni prima di tagliare.

3️⃣ macchina da taglio delle patate

Taglia con precisione le patate in patatine uniformi francesi con dimensioni di taglio regolabili per soddisfare le preferenze di mercato.

4️⃣ Machine risciacquo

Lava in modo efficace l'amido di superficie, impedire l'attacco e la garanzia di patatine più croccanti dopo la frittura.

5️⃣ macchina sbiancante

Strisce di patate pre-cooks a temperature controllate, Preservare il colore, Migliorare la trama, ed estendendo la durata di conservazione.

6️⃣ Macchina per disidratazione

Rimuove l'eccesso di acque superficiali dalle patatine sbollenarie, Ridurre gli schizzi di olio e migliorare l'efficienza fritta.

7️⃣ macchina da frittura continua

Fritte le strisce di patate a temperatura e tempo ottimizzate per ottenere la consistenza croccante desiderata e il colore dorato.

8️⃣ macchina per deoiling

Utilizza la forza centrifuga per rimuovere l'olio in eccesso, con conseguente più leggero, patatine fritte più sane con una migliore sensazione in bocca.

9️⃣ congelatore IQF (Freezing singolo rapido)

Congela rapidamente le patatine fritte per bloccare la freschezza, struttura, e sapore, Ideale per lo stoccaggio e la distribuzione.

🔟 Machine di imballaggio automatico

Pesa, borse, e sigilli patatine fritte in vari formati di imballaggio, Pronto per i canali di vendita al dettaglio o alimentare.

video

Principio di funzionamento

La linea di produzione automatica di patatine fritte presenta i vantaggi di un basso investimento una tantum, basso consumo energetico, molteplici funzioni, piccolo volume, alto profitto, uso e manutenzione convenienti. Il set completo di attrezzatura è composto da pulizia e sbucciatura, affettare (striscia), sbollentare, disidratazione, frittura con acqua e olio, disoleazione, stagionatura, imballaggio e attrezzature ausiliarie.

🌟 linea di lavorazione delle patatine francese Caratteristiche

- Completamente automatizzato, Linea di produzione integrata

Completa automazione dall'assunzione di patate crude alla confezione finale. -

Configurazione della linea personalizzabile & Capacità di output

Il design modulare consente configurazioni flessibili per diverse scale di produzione. -

Gestione avanzata di petrolio & Sistema di filtrazione

La filtrazione integrata garantisce una qualità e una longevità ottimale dell'olio. -

Efficiente dal punto di vista energetico & Costruzione in acciaio inossidabile sicuro

Costruito con acciaio inossidabile di alto grado per igiene, durata, ed efficienza energetica.

Vantaggi della linea di produzione di patatine fritte di patate

-

Operazione senza soluzione di continuità

Liscio, Flusso di lavoro continuo con intervento manuale minimo. -

Modulare & Design scalabile

Facilmente adattabile alle varie esigenze di produzione-dalle piccole startup a fabbriche su larga scala. -

Qualità dell'olio ottimizzata & Consumo ridotto

La gestione intelligente dell'olio abbassa l'utilizzo dell'olio ed estende la durata del petrolio, Migliorare l'efficienza dei costi. -

Igienico & Design durevole

Facile da pulire, resistente alla corrosione, e pienamente conforme agli standard internazionali di trasformazione alimentare.

🎯 Vantaggi automatici della linea di produzione fritte francesi

- Maggiore efficienza di produzione & Minori costi di manodopera

L'automazione riduce significativamente la necessità di lavoro manuale e aumenta la produzione. -

Investimento flessibile & Crescita aziendale

Scegli la capacità della linea in base alle esigenze attuali e aumentano all'aumentare della domanda. -

Patatine fritte più sane con gusto superiore

La qualità di frittura costante offre croccante, d'oro, e patatine fritte più sane che soddisfano le moderne aspettative dei consumatori. -

Conformità del mercato & Produzione pronta all'esportazione

L'attrezzatura incontra HACCP, CE, e requisiti FDA, Consentire l'ingresso sicuro nei mercati globali.

📊 pianta di lavorazione delle patatine francese Prova

- Adottato dai leader globali

Affidati e utilizzati dai principali produttori di patatine fritte congelate in Europa, Sud -est asiatico, e il Medio Oriente. -

Scalabilità comprovata

Opzioni di capacità di produzione da 300 kg/h a 3,000 kg/h - Scalabile con la crescita del business. -

Risparmio dei costi verificati

I clienti si riferiscono a 40% riduzione Nella frequenza di sostituzione dell'olio grazie alla gestione avanzata dell'olio. -

Assicurazione della qualità certificata

Completamente certificato per la sicurezza alimentare globale (HACCP, CE, FDA), con installazioni in più mercati internazionali.

Conclusione

IL Linea di produzione di produzione automatica di patatine fritte francese è l'investimento ideale per le aziende che mirano a produrre patatine fritte premium che soddisfano le aspettative dei consumatori di oggi per la qualità, struttura, e sapore. Dal taglio di precisione alla frittura controllata e al congelamento rapido, Ogni palcoscenico è progettato per preservare la naturale bontà della patata mentre fornisce le iconiche patatine dorate croccanti amate in tutto il mondo.

📩 Pronto a elevare la produzione di patatine francese?

👉 Contattaci oggi per una proposta personalizzata, Specifiche dettagliate, e consigli di esperti su misura per le tue esigenze di elaborazione!