ELENCO PRODOTTI

Acciaio in acciaio inossidabile per olio di cottura a fritta rotonda.

Dettagli del prodotto:

| Luogo d'origine: | Zhengzhou,Henan,Cina |

|---|---|

| Marchio: | HUAFOOD |

| Certificazione: | ISO,CE,SGS |

| Numero di modello: | HQC-612D |

| Materiale filtrante: | frittura usata-cottura, noce di cocco, arachidi, palma, soia, sesamo, girasole, ruota, cucinando, oliva, mostarda |

|---|---|

| Profondità del filtro: | 5-filtrazione a strati |

| Principio: | Centrifugo sotto vuoto |

| Effetto filtro: | 99% |

video

Introduzione

La macchina per purificare il filtro dell'olio da cucina per frittura a secchio rotondo in acciaio inossidabile è un'apparecchiatura integrata per la purificazione dell'olio progettata per friggitrici e coppe dell'olio di piccole e medie dimensioni. La macchina per il filtraggio dell'olio da cucina rimuove efficacemente i residui nell'olio attraverso la preestrazione sotto vuoto e la filtrazione a cinque stadi per evitare che l'olio diventi acido e produca sostanze nocive. Il corpo della macchina e il secchio di raccolta dell'olio sono realizzati in materiale alimentare resistente alle alte temperature e alla corrosione 304 acciaio inossidabile, che soddisfa gli standard internazionali di salute e sicurezza.

Nelle cucine commerciali e nelle catene di ristorazione, L'acciaio inossidabile della macchina per purificare il filtro dell'olio da cucina per frittura a secchio rotondo consente la rimozione continua del pangrattato, particelle carbonizzate e minuscole sostanze sospese nell'olio attraverso un efficiente sistema di filtraggio a cinque stadi e la funzione di allarme del vuoto, prolungando così notevolmente la durata dell'olio e mantenendo la consistenza del gusto del cibo. L'attrezzatura utilizza 100% Setaccio a rete in acciaio inossidabile per uso alimentare SUS304, che è resistente alle alte temperature e alla corrosione, facile da pulire e durevole. Non solo integra l'aspirazione del vuoto e la circolazione automatica per garantire il funzionamento stabile della macchina per il filtraggio dell'olio da cucina in ambienti ad alto carico, ma può anche essere spostato tramite rotelle o installazione fissa per soddisfare in modo flessibile le esigenze dei diversi spazi della cucina.

Macchina per filtro dell'olio da cucina per parametri tecnici friggibili

| Modello | HLY63-A | HLY125-A | HLY125-A |

| Numero di strati di filtro | Tipo a cinque segmenti | Tipo a cinque segmenti | tipo a tre segmenti |

| Quantità di filtraggio dell'olio | 30l/min | 80l/min | 80l/min |

| zona filtro | 1.03m2 | 2.0M2 | 1.2M2 |

| pressione di uscita | 0.5MPa | 0.5MPa | 0.5MPa |

| Energia | 1.5chilowatt | 3.0chilowatt | 3.0chilowatt |

| Peso | 180kg | 550kg | 550kg |

| Voltaggio | 380V/50 Hz | 380V/50 Hz | 380V/50 Hz |

| Diametro del tubo di ingresso dell'olio | 1.0 pollici | 2.0 pollici | 2.0 pollici |

| Diametro del tubo di uscita dell'olio | 1.0 pollici | 1.5 pollici | 1.5 pollici |

| Dimensioni della macchina | 850*850*1100mm | 1100*1000*1300mm | 1100*1000*1300mm |

Principio di funzionamento della macchina del purificatore del filtro dell'olio per frittura a secchio rotondo

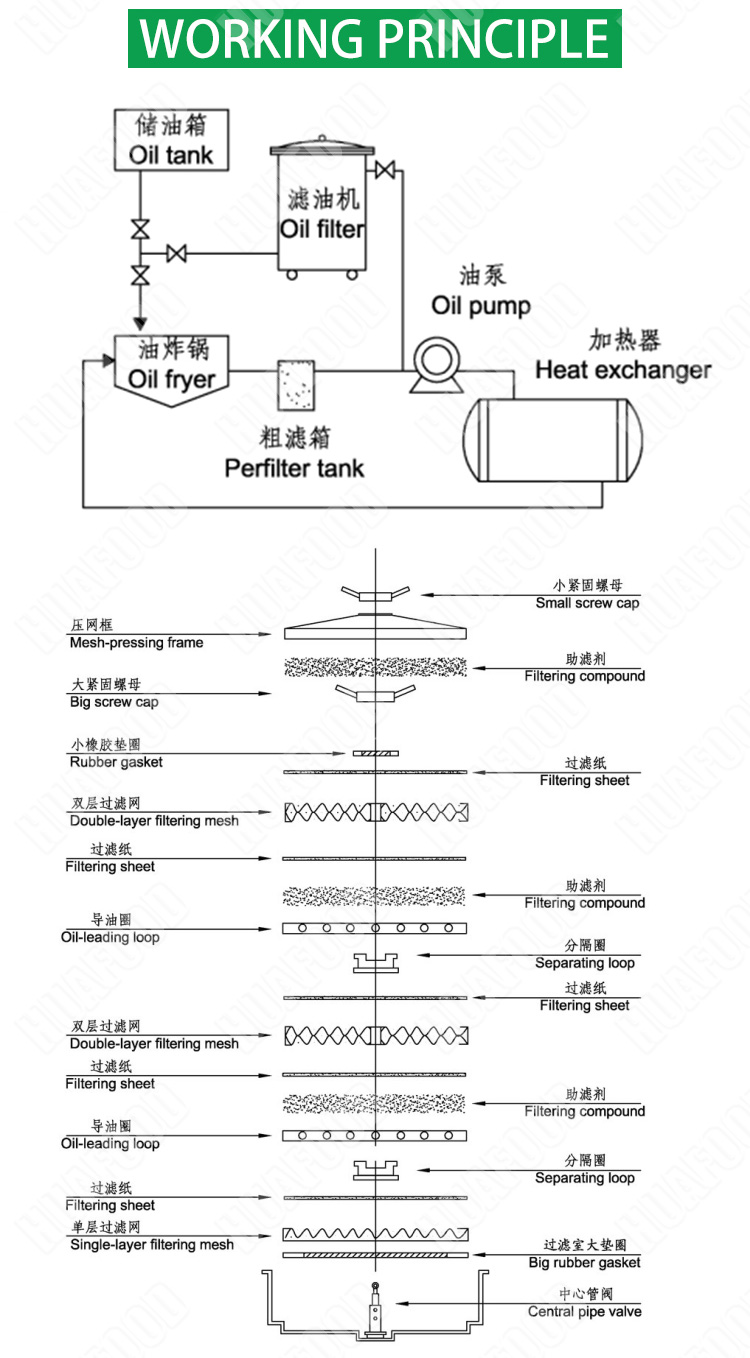

La macchina purificatrice del filtro dell'olio da cucina per frittura a secchio rotondo funziona aspirando l'olio da cucina caldo dalla friggitrice in un'unità di filtraggio sigillata, facendolo passare attraverso elementi filtranti multistadio per rimuovere il particolato grossolano e fine, quindi utilizzando una camera a vuoto per disidratare e degassare l'olio, e infine il ricircolo dell'olio purificato nella friggitrice, sotto il pieno controllo del PLC per garantire la continuità, funzionamento efficiente.

1. Aspirazione e aspirazione dell'olio

La pompa dell'olio della macchina crea un'aspirazione per aspirare l'olio usato dalla friggitrice all'unità di filtraggio. Alcuni modelli utilizzano una pompa volumetrica o a ingranaggi per mantenere un flusso costante indipendentemente dalle variazioni di viscosità dell'olio.

2. Filtrazione multistadio

2.1 Grossolano (Superficie) Filtrazione

Primo, l'olio passa attraverso una maglia grossa o uno schermo metallico che cattura grandi briciole e detriti carbonizzati (>200 µm)

2.2 Bene (Profondità) Filtrazione

Prossimo, l'olio scorre attraverso le cartucce del filtro di profondità, spesso strati di cellulosa o tessuto, che intrappolano i solidi più piccoli (10–100 µm) all'interno dello spessore del mezzo filtrante

2.3 Media specializzati (Adsorbimento / Rottura dell'emulsione)

Nelle unità avanzate, i carboni attivi o i setacci molecolari rimuovono gli acidi grassi liberi, corpi di colore, e acqua emulsionata, migliorare la limpidezza e la stabilità dell'olio

3. Disidratazione sotto vuoto & Degasaggio

L'olio parzialmente filtrato entra in una camera a vuoto dove la pressione del sistema viene ridotta a circa –0,06 MPa, abbassando il punto di ebollizione dell'acqua per facilitare la rapida evaporazione dell'umidità. Sotto vuoto, gas disciolti (ossigeno, CO₂) evolvono anche fuori soluzione, riducendo i percorsi di degradazione ossidativa nell’olio .

4. Flusso guidato dalla pressione attraverso il mezzo filtrante

Un differenziale di pressione controllato (fino a 0.4 MPa) attraverso gli elementi filtranti forza l'olio attraverso le strutture dei pori, garantendo che le particelle fini rimangano sul lato a monte mentre l'olio pulito esce a valle.

5. Ricircolo continuo

Una volta disidratato e degasato, l'olio purificato viene pompato nuovamente nella vasca della friggitrice, stabilendo una circolazione a circuito chiuso che mantiene la qualità dell'olio durante le operazioni di frittura prolungate .

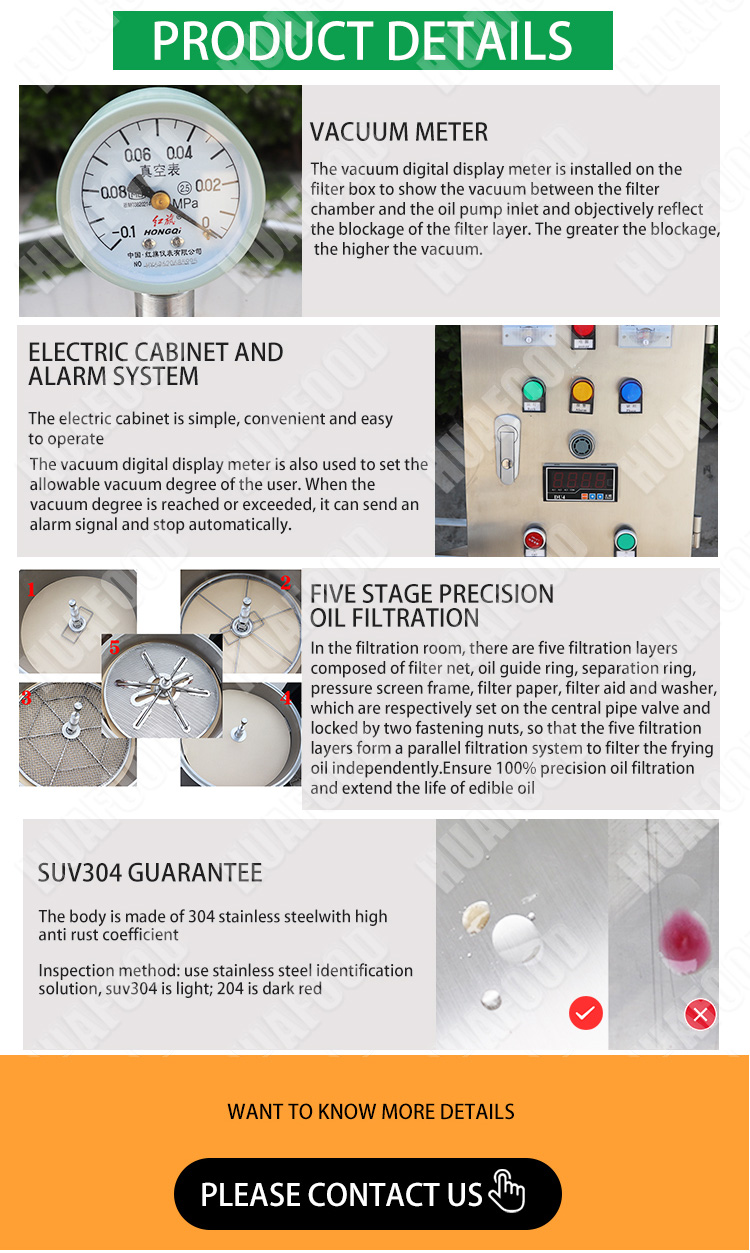

6. Sistema di controllo & Caratteristiche di sicurezza

I sensori integrati monitorano il livello di vuoto, temperatura dell'olio, e la pressione differenziale tra i filtri; si verificano allarmi o arresti automatizzati se le soglie vengono superate per prevenire il sovraccarico del filtro o la cavitazione della pompa. Molte unità utilizzano la logica PLC per sequenziare l'azionamento della valvola, velocità della pompa, ed elementi riscaldanti, consentendo il funzionamento con un solo pulsante e la diagnostica remota

Attraverso questa combinazione di aspirazione, rimozione graduale del particolato, disidratazione sotto vuoto, e il flusso guidato dalla pressione, sotto controllo automatizzato, la macchina purificatrice del filtro dell'olio da cucina per frittura a secchio rotondo offre un'erogazione continua, purificazione dell'olio ad alta efficienza, prolungare la durata dell'olio, miglioramento della qualità del cibo, e riducendo i costi operativi.

Vantaggi del filtro dell'olio di raffreddamento verticale

Facile da pulire, nessun residuo di olio, nessun blocco;

Utilizzare la pressione positiva per massimizzare l'efficienza di filtrazione;

L'olio dopo la filtrazione della pressione dell'aria è limpido e puro, che prolunga la durata dell'olio per friggere e consente di risparmiare sui costi di produzione;

Migliorare la qualità del cibo: stabilizzare la temperatura e la pulizia dell'olio, in modo che il fritto abbia un colore dorato e un sapore croccante;

Estendere il ciclo di utilizzo dell'olio: rimuovere minuscole particelle, ridurre notevolmente la velocità di irrancidimento dell'olio, e ridurre la frequenza di sostituzione;

Ridurre i costi operativi: risparmiare sui costi di approvvigionamento e sui costi di trattamento dell'olio esausto attraverso la filtrazione continua e il riciclaggio dell'olio;

Applicazione della macchina per purificare il filtro dell'olio da cucina

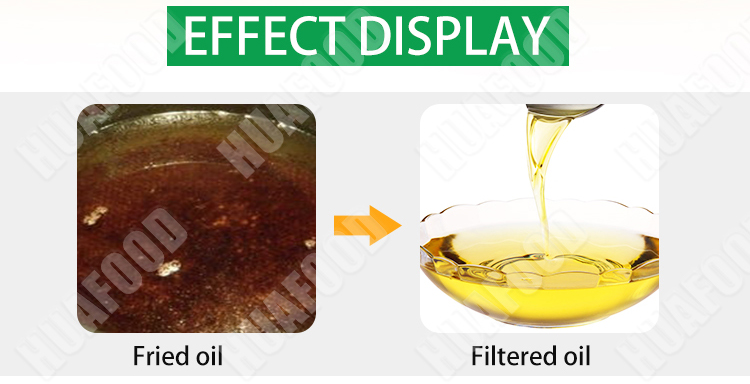

Come sappiamo, il processo di produzione alimentare richiederà molto tempo per friggere l'olio , e la qualità diminuirà gradualmente. i prodotti fritti appaiono neri, l'odore dell'olio, alto contenuto di olio, il valore di acidità e il valore di perossido vengono superati, fumo e così via. Influiscono notevolmente sulla percezione del cibo da parte del cliente. E portano anche problemi di igiene e sicurezza alimentare. Perciò, l'olio di frittura deve essere sostituito dopo un periodo di utilizzo, Tuttavia, spesso la sostituzione dell'olio di frittura comporta un aumento dei costi di produzione. L'uso delle apparecchiature di filtraggio dell'olio di frittura HFD sarà in grado di risolvere i problemi di cui sopra. La macchina per il filtro dell'olio per frittura può prolungare la durata dell'olio, risparmiando sul costo del petrolio.

Caratteristiche del filtro dell'olio per frittura a secchio rotondo

Tutto 304 materiale in acciaio inossidabile: resistente alle alte temperature, resistente alla corrosione, facile da pulire, e prolungare la durata dell'apparecchiatura;

Sistema di filtraggio a cinque livelli: dalla filtrazione grossolana alla filtrazione fine, gli schermi a rete multistrato rimuovono gradualmente le impurità di diverse dimensioni delle particelle;

Mobile e fisso a duplice scopo: dotato di ruote ad alto carico, oppure può essere fissato sotto il banco di lavoro, distribuito in modo flessibile in diversi layout di cucina;

Funzione allarme vuoto: monitoraggio in tempo reale dello stato di filtrazione, prevenire il blocco della linea dell'olio, e garantire un funzionamento continuo e stabile della macchina per il filtro dell'olio da cucina;

Vantaggi della macchina per il filtro dell'olio della friggitrice in acciaio inossidabile

Ottimizzazione dello spazio: design a canna compatta, Piccola impronta, facile da integrare nel layout del banco da lavoro della cucina sul retro;

Tutela dell'ambiente e risparmio energetico: ridurre le emissioni di oli usati, soddisfare gli standard della cucina ecologica, e ridurre il consumo di energia e lo spreco di acqua;

Facile da usare: avvio con un solo pulsante, filtrazione a circolazione automatica, non c'è bisogno di personale di manutenzione professionale, riducendo notevolmente la difficoltà del funzionamento manuale;

Prova

Caso di applicazione industriale: Molte catene di fast food e gruppi alberghieri utilizzano questa macchina per filtrare l'olio da cucina, il ciclo di sostituzione del grasso è stato prolungato di oltre 50%, e il costo del petrolio è stato ridotto di 30%;

Elogio dell'utente: Il feedback dei clienti ha detto “funzionamento facile, filtrazione approfondita, risparmio sui costi”, e l'apparecchiatura ha mantenuto prestazioni elevate anche dopo oltre 3,000 ore di funzionamento stabile;

Conclusione

Questa macchina per purificare il filtro dell'olio da cucina a secchiello rotondo in acciaio inossidabile combina una filtrazione ad alta efficienza, monitoraggio del vuoto e materiali interamente in acciaio inossidabile. È la scelta ideale per il settore della ristorazione per mantenere pulito l'olio, migliorare la qualità e ridurre i costi. Pronto per ottimizzare la gestione dei grassi in cucina? Lascia subito un messaggio online per ottenere un piano personalizzato e un preventivo preferenziale!

700-500-4.jpg)