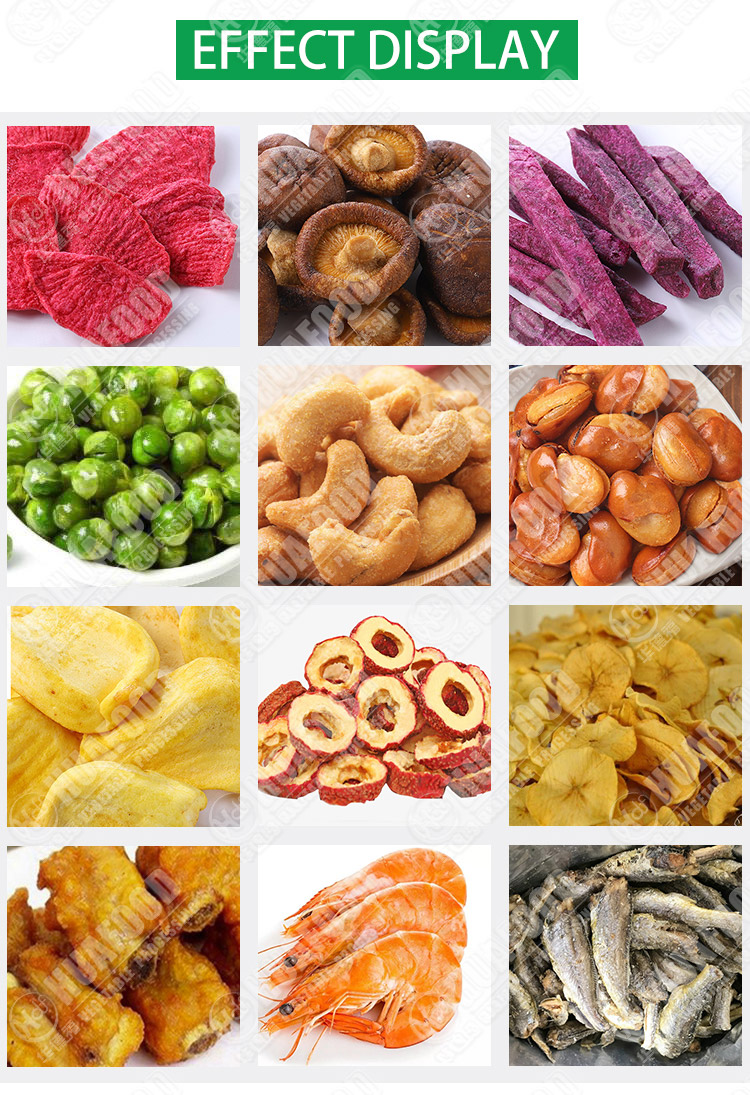

СПИСОК ПРОДУКТОВ

Промышленная вакуумная машина для фруктов и чипсов овощей

информация о продукте:

| Место происхождения: | Хэнань Хуафуд, Китай |

|---|---|

| Имя бренда: | ХУАФУД |

| Сертификация: | ИСО,CE,СГС |

| Номер модели: | ХДФ-ВФ-1000 |

| Приложение | широко используется при низкотемпературной жарке фруктов.,Овощи,Мясная пища,Сухофрукты. |

В современной индустрии снеков, потребительский спрос на здоровые, хрустящий, и продукты, богатые питательными веществами, привели к инновациям в пищевой промышленности.. The промышленная вакуумная жарочная машина это передовое решение, разработанное специально для производства высококачественных фруктово-овощные чипсы. В отличие от традиционных способов жарки, это оборудование работает в условиях низкой температуры и вакуума., что помогает сохранить естественный цвет, вкус, и питательная ценность фруктов и овощей при достижении идеальной хрустящей текстуры.

Параметры вакуумной фритюрницы

|

Имя

|

Вакуумная фритюрница

|

|

Модель

|

ХФЗК-50 |

|

Напряжение

|

380в

|

|

Масса

|

1000кг

|

|

Материал

|

304 нержавеющая сталь

|

|

Количество корзин

|

1

|

|

Режим отопления

|

Газ/Электричество/Пар

|

|

Рабочая температура

|

80-120℃,можно настроить

|

|

Власть

|

11кВт

|

|

Емкость масла

|

78л

|

|

Обезжиренная форма

|

Обезжиривание вакуумной центрифуги

|

|

Емкость

|

Около 40-50 кг/партия

|

видео

Принцип работы промышленной вакуумной жарочной машины

Продукт в состоянии отрицательного давления может уменьшить или даже избежать вреда, вызванного окислением., в состоянии отрицательного давления масла в качестве теплоносителя, вода внутри пищи будет быстро испаряться, образуя рыхлую пористую структуру. Небольшое содержание масла. Хороший вкус и хороший внешний вид. Жарка в вакууме предназначена для жарки и обезвоживания продуктов при низкой температуре. (80~120℃), который может эффективно уменьшить вред, наносимый высокой температурой пищевому питанию..

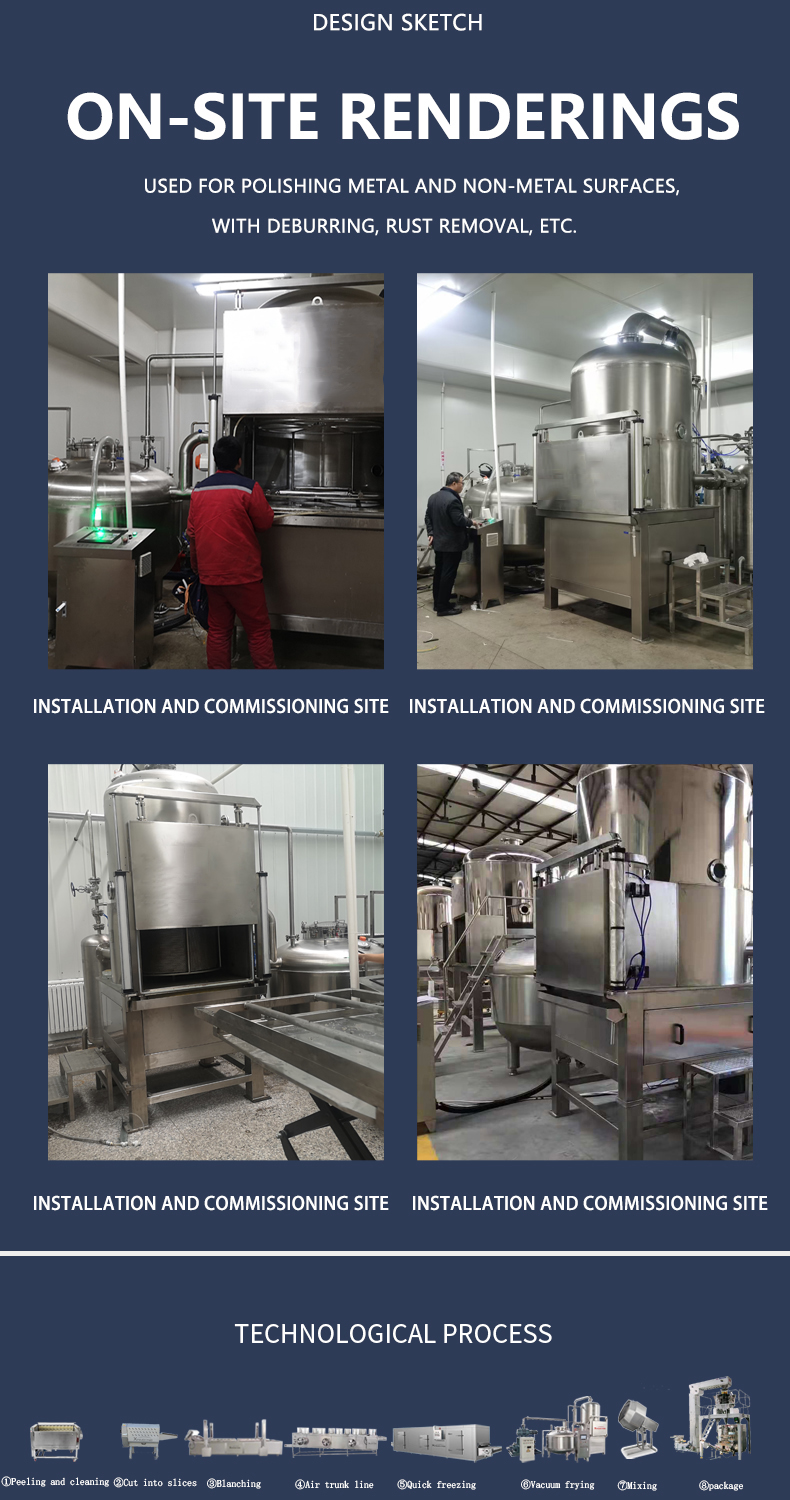

Особенности вакуумной фритюрницы

Наш промышленная вакуумная жарочная машина изготовлен из пищевой нержавеющей стали и оснащен высокопроизводительным вакуумным насосом., низкотемпературная система отопления, и автоматическая установка фильтрации масла. Система работает в закрытой вакуумной среде., обычно между 80–120°C, который идеально подходит для жарки богатых влагой фруктов и овощей, таких как бананы., яблоки, морковь, тыквы, бамия, и еще.

-

Двухслойная или однослойная жарочная камера по выбору.

-

Интеллектуальное управление ПЛК с интерфейсом сенсорного экрана.

-

Автоматический контроль уровня масла и фильтрация остатков

-

Интегрированная система обезжиривания для окончательной хрусткости.

Преимущество вакуумной фритюрницы

По сравнению с обычным жарочным оборудованием, Наша промышленная вакуумная жарочная машина предлагает следующие преимущества:

Низкотемпературная обработка: Предотвращает чрезмерное потемнение или подгорание, сохранение натуральных пигментов и вкуса фруктов и овощей.

Обеспечение качества масла: Встроенная система фильтрации снижает окисление., продление срока службы масла и снижение эксплуатационных расходов.

Эффективное удаление влаги: Улучшает хрусткость, уменьшая поглощение масла, в результате чего становится легче, более здоровые чипсы.

Минимальная потеря питательных веществ: Сохраняет витамины, ферменты, и антиоксиданты, которые в противном случае разлагались бы при высокой температуре..

🔚 Заключение

Наш промышленная вакуумная жарочная машина в настоящее время используется предприятиями пищевой промышленности в Юго-Восточной Азии., Европа, и Латинская Америка. Клиенты сообщают об увеличении стабильности продукта на 30–40 %., снижение расхода масла до 35%, и значительно улучшена однородность продукта. Система получила высокую оценку за автоматизацию., надежность, и низкие требования к техническому обслуживанию.

Филиппинский экспортер закусок, использующий наше оборудование, успешно вышел на рынки здоровых закусок Японии и Кореи благодаря превосходной текстуре и сохранению цвета своих чипсов из манго и сладкого картофеля..

В итоге, тот промышленная вакуумная жарочная машина является идеальным решением для производства питательных, хрустящий, и яркий фруктово-овощные чипсы. Благодаря низкотемпературному процессу жарки и передовой вакуумной технологии., обеспечивает сохранение вкуса, меньшее содержание масла, и увеличенный срок хранения — все ключевые качества, которые современные потребители ценят в здоровых закусках..

📩 Свяжитесь с нами сегодня чтобы узнать больше о том, как наша промышленная вакуумная жарочная машина может улучшить ваши возможности обработки пищевых продуктов.. Оставьте нам сообщение сейчас и получите индивидуальное предложение и техническую спецификацию, адаптированную к вашим производственным потребностям.!