PRODUCTS LIST

High Efficiency Plantain Flour Production Line For Sale

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | HUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | Cutomized |

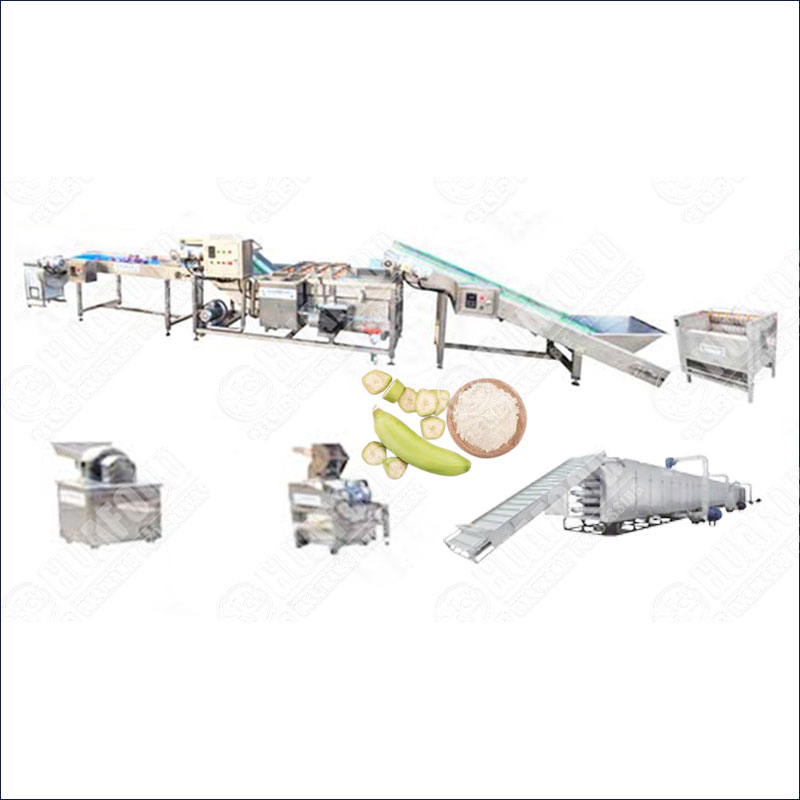

High Efficiency Plantain Flour Production Line For Sale is a fully automated processing equipment specially designed for high-yield banana plantain, with high throughput and low energy consumption. The production line runs the entire process of raw plantain from washing, peeling, slicing to drying, crushing, screening, and packaging, accurately controlling temperature and humidity to maintain the stability of raw material nutrients and taste.

Plantain Flour Production Process

Washing → Peeling → Slicing/Peeling → Hot Air Drying → Crushing → Screening → Packaging

1. Blanching & Cleaning

Blanching & Cleaning Machine: It adopts stainless steel rotary belt or mesh belt design, uses hot water or steam to blanch, inhibit enzyme activity, maintain the original color of plantain, and removes impurities with the help of spraying or drum cleaning, which has both sterilization and color protection functions

2. Peeling

Peeling Machine: SUS304 food-grade stainless steel structure, using arc scraper or air pressure assistance, suitable for plantains of different maturity, automatically peeling the peel through roller or scraper, high efficiency and no damage to the flesh.

3. Slicing/Peeling

Slicer: Adjustable thickness blade (usually 2-4mm), using food-grade stainless steel conveyor belt, slices are flat and even, avoids fragmentation, and improves the consistency of drying and crushing.

4. Hot Air Drying

Hot Air Dryer: Uses low temperature constant control (40-65℃) hot air drying, multi-layer mesh belt or hot air circulation structure, and controls the time for 15-18 hours to a moisture content of <13%, which is both energy-saving and color-preserving.

5. Grinding

Grinding machine (hammer/air flow grinding): The air-cooling or water-cooling system stabilizes the grinding temperature at <80℃, and the particle size after grinding is adjustable (20-120 mesh), which can meet light food and industrial purposes.

6. Sieving

Vibration/rotary vibration screen: Fully closed design, using multi-layer screens (60-100 mesh), separating coarse powder from fine powder, supporting multi-stage screening, reducing dust leakage, and ensuring uniform particles.

7. Packaging

Packaging machine (screw filling type): suitable for bulk or bag packaging (10g-1kg), automatic weighing, powder suction, sealing, coding process, efficient and accurate, avoiding secondary contamination.

Video

Plantain Flour Production Line Advantages

The equipment is specially designed for plantain with high starch content, and its drying efficiency is 20% higher than that of ordinary starch equipment.

Low energy consumption and good dust control greatly improve the environmental hygiene and operation safety of the workshop.

The powdering rate is as high as 98%, and the powder particle size can be adjusted between 100-200 mesh to meet the markets in different regions (for example, Ghana has a large demand for coarse powder in its diet).

Plantain Flour Processing Line Features

Compact structure and modular design, easy installation, flexible expansion of production capacity;

PLC touch screen centrally controls the operation of the entire line, with high degree of automation and easy operation;

Multi-stage temperature control and variable frequency deceleration control, processing can be adjusted according to plantain characteristics to adapt to different varieties and maturity;

Benefits

The equipment helps local small and medium-sized farms to form an industrial chain integration and enhance the economic value of plantain.

Dry powder is easy to store and has low transportation costs. It can be extended to the export grain processing chain to increase foreign exchange earnings.

Aiming at the frying and cooking processing methods of plantain in Africa, the original color and taste of the powder are maintained, enhancing market recognition.

Conclusion

High Efficiency Plantain Flour Production Line is specially optimized for plantain flour processing, covering the entire process from washing, peeling, slicing, drying, crushing to packaging, and modular design to meet the needs of prolific countries. The equipment ensures high powdering rate, low energy consumption, and automated control, helping plantain producing companies such as Nigeria, Ghana and Cameroon to optimize costs, increase production capacity and brand competitiveness.

📩 Welcome to leave a message online to get free equipment solutions and quotes. Let us work together to create a new era of plantain processing and open up a broader local and international market!