PRODUCTS LIST

Automatic Carrot Root Vegetable Washing Drying Machine Processing Line

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | FUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | HDF100 |

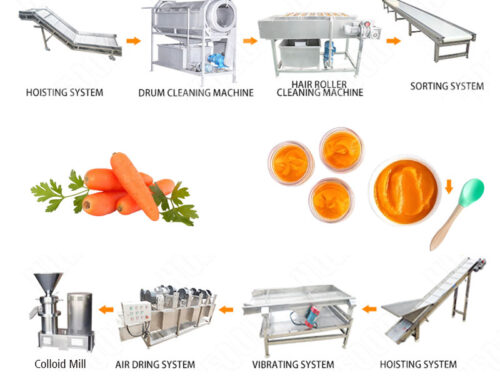

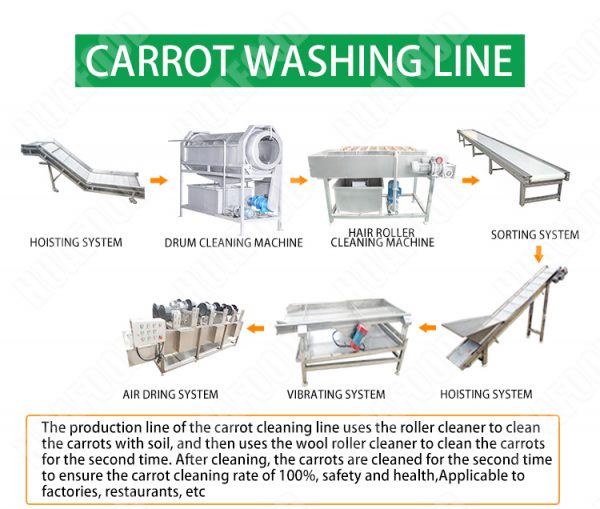

Carrot Washing And Drying Line Introduction

The carrot washing drying processing line uses the roller cleaner to clean the Carrots with soil, and then uses the wool roller cleaner to clean the carrots for the second time. After cleaning, the carrots are cleaned for the second time to ensure the carrot cleaning rate of 100%, safety and health,Applicable to factories, restaurants, etc

Carrot processing equipment

| Total output of carrot washing line 1000 kg / h | ||

| Item | Power | Size |

| hoisting machine | 0.75kw/380v/50Hz | 2000*1000*1900mm |

| Drum cleaning machine | 3.75kw380v/50Hz | 3000*1100*2200mm |

| Hair roller cleaning machine |

2.0kw/380v/50Hz | 2000*1000*1300mm |

| sorting machine | 0.75kw/380v/50Hz | 3000*900*900mm |

| hoisting machine | 0.75kw/380v/50Hz | 2000*800*1600mm |

| vibrating machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| air drying machine | 15kw/380v/50Hz | 4000*1200*1400mm |

| Note: These parameters are conventional and can be customized according to customer needs | ||

Carrot Washing Machine Video

Carrot Washing Line Working principle

Carrot in cleaning groove is covered by water, attached to the surface of quite a number of large pieces of soil loss, the conveyor belt into the drum washing machine inlet, cleaning material into the hopper into the rotating drum, the drum rotation in the pool, use of its own gravity separation of cleaning as propulsion, to realize automatic cleaning material.

The carrot moves forward along the roller wall. During the movement, the carrot is constantly washed by water, the friction between carrot, the brushing between turning and the friction between cleaning material and the roller wall, and the cleaning process of carrot surface is completed under the joint action.

Carrot Root Vegetable Cleaning Process

- The first step is to put the carrots to be washed in a bubble washing machine;

- The second step is to use the conveyor belt to transfer the washed carrots to the drum washing machine for secondary washing to ensure that the vegetables are 100% clean;

- The third step is to remove some of the water in the carrots through a vibrating screen;

- The fourth step is to drain all the water from the carrots on the shaker into the air dryer;

- The fifth step is to cut the washed carrots as needed

Finally, according to your needs, you can cut, dry, freeze, pack, etc.

Carrot Washing Processing Line Features

Multi-stage assembly line design

Integrates preliminary mud removal, bubble cleaning, brush peeling, high-pressure spraying and air drying to achieve continuous processing;

304 food-grade stainless steel body

The entire line adopts SUS304 stainless steel, which is corrosion-resistant, easy to clean, and meets European and American export standards;

High-efficiency bubble cleaning system

The bubble tank uses strong rolling to remove surface dirt, and with multi-point spraying device, the cleaning rate is as high as 95%;

Adjustable brush peeling module

Adopting soft and hard brush rollers to effectively remove epidermis and surface impurities without damaging rhizomes;

High-pressure spraying and air drying system

Combined with high-pressure water guns and constant temperature air knives, rapid dehydration and drying provide clean, drip-free products for subsequent sorting and packaging;

Intelligent sorting and rejection

Can be configured with vibration or roller sorting devices to reject unqualified rhizomes according to size or weight to ensure the consistency of finished products;

Carrot Cleaning Line Benefits

Improve product quality: uniform washing and fast drying reduce microbial growth, ensuring carrots and other root vegetables have bright color and crisp taste.

Shorten processing cycle: end-to-end automated processing reduces traditional multiple processes to a straight line, increasing production efficiency by 2-3 times.

Enhance food safety: all stainless steel and food-grade belt design, in line with CE, FDA and HACCP standards, easy to inspect and comply with hygiene regulations.

Reduce maintenance costs: wear-resistant brush rollers and high-quality motors reduce failure rates, and annual maintenance investment is reduced by 40%.

This carrot washing processing line reconstructs the root vegetable processing flow through intelligent technology, compressing the traditional cleaning, sorting, and drying processes that require 12 people to complete into a fully automatic assembly line operation. It is particularly suitable for companies that pursue capacity upgrades and quality control standardization. By reducing manual intervention, reducing raw material losses, and ensuring food safety, it helps you establish core competitiveness in the global agricultural product trade.

Ready to optimize your carrot root vegetable cleaning line?

👉 Leave a message online to get detailed plans and quotations. Our foreign trade team will provide you with one-stop customized services!