Linha de produção Complate Baba Ghanoush, da torrefação à embalagem

O Complete Baba Ghanoush Production Line is a sophisticated, turnkey industrial solution specifically engineered to replicate the authentic, smoky taste of traditional Middle Eastern eggplant dip on a commercial scale. From the precise high-temperature roasting of fresh eggplants to the final airtight packaging, this integrated system ensures consistent texture, rich flavor preservation, and the highest food safety standards. Designed for food processors seeking to automate the complex “smoky flavor” extraction and creamy emulsification process, our line maximizes yield while maintaining the artisanal quality that Baba Ghanoush consumers demand.

Baba Ghanoush Integrated Workflow Process

To ensure a seamless transition from raw ingredients to a shelf-ready product, the production line follows a rigorous, synchronized flow:

Eggplant Washing —→ Automatic Roasting (Charring) —→ Resfriamento & Descamação —→ Fine Grinding/Pulping —→ Mixing & Seasoning (with Tahini) —→ Vacuum Degassing —→ Automatic Filling & Embalagem

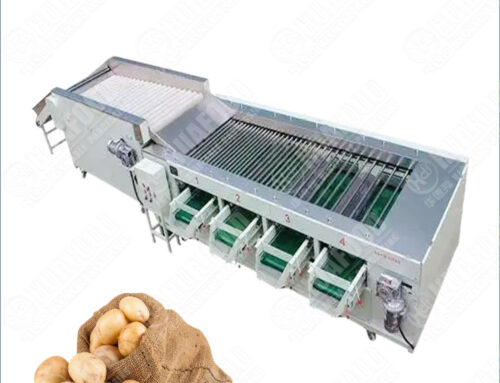

Baba Ghanoush Line Key Equipment

-

Industrial Bubble Washer: Uses high-pressure air bubbles and water sprays to thoroughly remove impurities from eggplant skins without damaging the flesh.

-

Continuous Gas/Electric Roaster: Replicates open-flame roasting to impart the essential “smoky” aroma and char the skin for easy removal.

-

Descamação: The rosted eggplant need manual peeling;

-

High-Shear Colloidal Mill: Grinds the eggplant flesh into a delicate, uniform paste while preserving its natural fiber structure.

-

Vacuum Emulsifying Mixer: Integrates tahini, alho, and lemon juice under vacuum conditions to prevent oxidation and ensure a creamy consistency.

-

Piston-Drive Filling Machine: Provides high-precision dosing for various container sizes, ensuring hygienic and drip-free packaging.

Baba Ghanoush Line Advantages

Unmatched Flavor Consistency: Eliminates the variables of manual roasting, ensuring every batch meets the same high-quality sensory standards.

High Output with Low Labor: Reduces the need for manual mixing, significantly cutting operational overhead and labor costs.

Extended Shelf Life: The vacuum mixing and hot-filling options minimize bacterial growth and prevent the dip from darkening due to oxidation.

Características do secador de correia de malha contínua

-

All-in-One Automation: A fully closed-loop system that covers everything from raw eggplant treatment to the finished dip.

-

Authentic Smoke Infusion Tech: Specialized roasting modules designed to create the signature charred flavor profile of real Baba Ghanoush.

-

SUS304/316 Construction: Built entirely with food-grade stainless steel, featuring CIP (Clean-in-Place) compatibility for rapid sanitation.

-

PLC Intelligent Control: Centralized Siemens/Schneider touch-screen interface for real-time monitoring of roasting temperatures and mixing speeds.

Eggpalnt Paste Line Benefits

Rapid Market Entry: Deploy a “plug-and-play” factory solution that allows you to start large-scale production immediately with minimal R&D.

Reputação de marca aprimorada: Deliver a premium, artisanal-grade product that wins customer loyalty through superior texture and taste.

Scalable ROI: The high efficiency and reduced waste of the automated line ensure a faster return on investment compared to semi-automatic setups.

Conclusão

Investing in a Complete Baba Ghanoush Production Line is the key to transforming a traditional recipe into a global commercial success. By integrating advanced roasting technology with precision packaging, our solution ensures your product stands out in the competitive “Pronto para comer” dip market for its quality, segurança, and authentic Mediterranean soul.

Ready to scale your production? Don’t let manual processing limit your growth. Deixe-nos uma mensagem online hoje to receive a customized technical proposal and a factory-direct quote. Our engineers are standing by to help you design the perfect line for your facility!