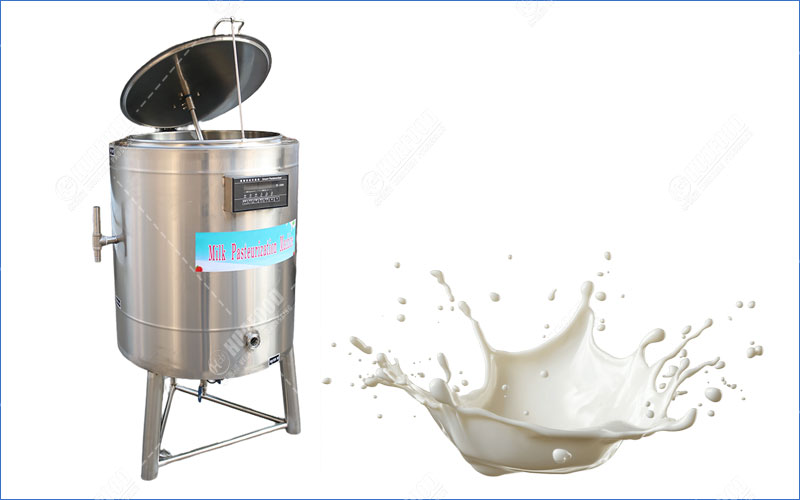

Pasteurizador comercial de leite com 304 Higiene SS para pequenas fazendas

O Commercial Milk Pasteurizer is a critical post-milking solution specifically designed for small-scale dairy farms and artisanal milk producers. Recognizing that raw milk is a highly perishable biological liquid rich in nutrients but also prone to rapid bacterial growth, this equipment provides a precise thermal treatment. Built with 304 Aço inoxidável (SS) Higiene padrões, it ensures the elimination of harmful pathogens like Salmonella e Listeria while meticulously preserving the milk’s natural flavor, cream line, and nutritional bioavailability. This compact yet powerful unit is the bridge between raw farm production and safe, marketable dairy products.

Commercial Milk Pasteurizer Working Principle

This pasteurizer utilizes the Low-Temperature Long-Time (LTLT) method, also known as batch pasteurization. The milk is poured into the internal 304 SS chamber, which is surrounded by a water jacket. Heating elements warm the water, which indirectly transfers heat to the milk to prevent “scorching” ou “queimado” flavors—a common risk with direct heating. An integrated agitator ensures the milk stays in constant motion for uniform heat distribution. Once the target temperature (typically 63°C-65°C) is reached and held for 30 minutos, the system initiates a cooling phase, rapidly bringing the milk down to storage temperature to lock in freshness.

Small Milk Pasteurizer Machine Advantages

-

Pathogen Elimination: Effectively kills 99.9% of harmful bacteria, extending the shelf life of your farm-fresh milk significantly.

-

Flavor Retention: Unlike UHT processing, this batch pasteurizer keeps the “farm-fresh” taste that specialty customers crave.

-

Compact Footprint: Ideal for small farms or boutique dairy shops where floor space is limited but commercial performance is required.

-

Easy Sanitation: The seamless welding and polished interior make the “Clean-in-Place” (CIP) process simple and efficient.

Milk Pasteurizer Features

-

Construção SUS304 de qualidade alimentar: Every surface in contact with milk is crafted from high-polished 304 aço inoxidável, preventing lactic acid corrosion and bacterial hiding spots.

-

Gentle Indirect Heating System: Uses a water-jacketed design to ensure the milk’s delicate proteins and fats aren’t damaged by hotspots.

-

Automatic Agitation Blade: A low-speed, high-torque stirrer maintains milk homogeneity and prevents the formation of a “milk skin” during heating.

-

Intelligent Temperature Sensors: Dual-probe technology monitors both the water jacket and the milk temperature for surgical precision.

Milk Pasteurizer Machine Benefits

Increased Revenue: Turn raw milk into a value-added, legally salable beverage for local markets and cafes.

Reduced Waste: By extending the freshness window, you minimize losses from unsold raw milk that would otherwise sour.

Consumer Trust: Providing pasteurized milk demonstrates a commitment to public health and food safety, building long-term brand loyalty.

Low Operational Cost: Designed for energy efficiency, allowing small farms to process daily yields without high electricity bills.

Conclusão

O Pasteurizador comercial de leite com 304 SS Hygiene is more than just a machine; it is a safeguard for your dairy business. By balancing rigorous hygiene standards with the delicate thermal needs of fresh milk, it allows small farms to produce high-quality, seguro, and delicious dairy products that stand out in a competitive market.

Ready to start your own dairy processing journey? Don’t let your high-quality milk go to waste. Deixe uma mensagem abaixo hoje to get a detailed quote, technical specifications, and expert advice on choosing the right capacity for your farm!