LISTA DE PRODUTOS

HDFW-6E Máquina de lavar vegetais de alta eficiência, alho-poró, cebola verde, máquina de limpeza

Detalhes do produto:

| Lugar de origem: | Zhengzhou,Henan,China |

|---|---|

| Marca: | HUAFOOD |

| Certificação: | ISO,CE,GV |

| Número do modelo: | HDFW-6E |

Vídeo

Parâmetros

Esta é uma linha de processamento completa, adequado para vários tipos de vegetais, como cenoura, batata, repolho, cebola, etc..

Cenários aplicáveis: supermercados, restaurantes, plantas de processamento de alimentos, congelamento de plantas, plantas de processamento de frutas secas,fábrica de processamento de cobras

| Produção total da linha de lavagem de cenoura 500-1000 kg / h | ||

| Item | Poder | Tamanho |

| Máquina de lavar bolhas | 3.75kw/380v/50Hz | 4000*1200*1300milímetros |

| máquina de elevação | 0.75kw/380v/50Hz | 2000*1000*1900milímetros |

| Máquina de limpeza de rolo de cabelo | 2.0kw/380v/50Hz | 2000*1000*1300milímetros |

| máquina vibratória | 1.5kw/380v/50Hz | 1500*1000*1300milímetros |

| máquina de secagem a ar | 15kw/380v/50Hz | 4000*1200*1400milímetros |

| Observação: Esses parâmetros são convencionais e podem ser customizados de acordo com a necessidade do cliente | ||

.

Princípio de trabalho

procedimento

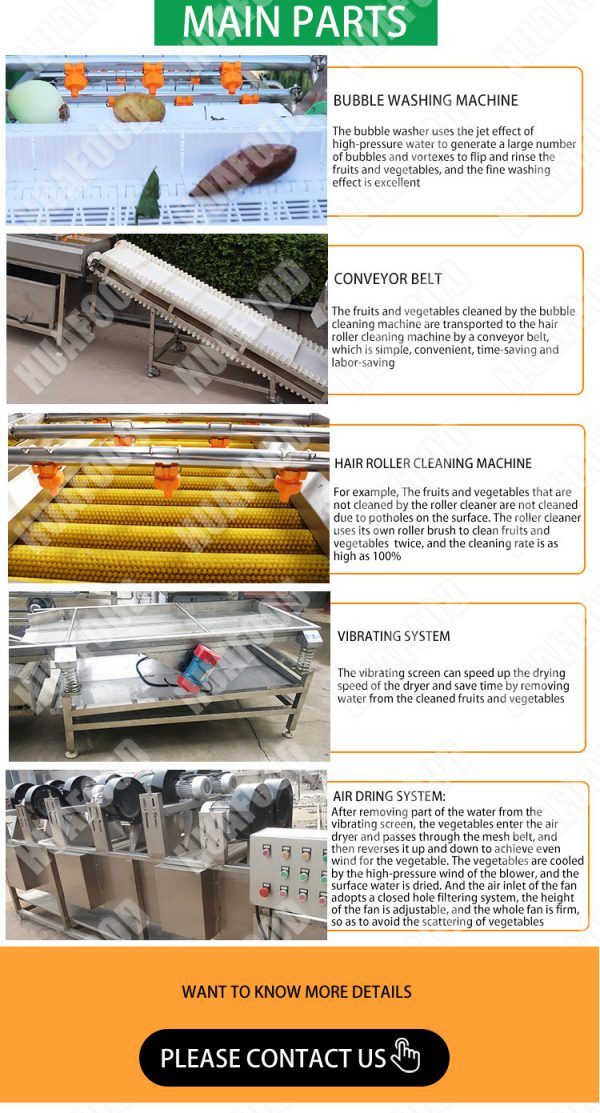

1.O primeiro passo é colocar os vegetais e frutas que precisam ser limpos na máquina de lavar bolhas para limpeza;

2.a segunda etapa é usar a correia transportadora para transferir as frutas e vegetais lavados para a máquina de lavar rolo de cabelo para limpeza secundária para garantir que os vegetais estejam limpos 100%;

3.o terceiro passo é retirar um pouco da água das frutas e vegetais através da peneira vibratória;

- a quarta etapa é retirar toda a água das frutas e vegetais da peneira vibratória para o secador de ar;

5.o quinto passo é cortar as frutas e vegetais limpos de acordo com a necessidade

Finalmente, de acordo com suas necessidades, você pode cortar, seco, congelar, pacote, etc..

Máquinas de processamento de vegetais

Talentos

1. O equipamento é limpo em duas etapas antes e depois das duas etapas. A água circulante interna é limpa em todos os níveis, e o suporte de pulverização está conectado à água da torneira para limpeza secundária.

2. A pressão da água de pulverização é ajustável, e o volume borbulhante é ajustável.

3. Esterilização UV, esterilização por ozônio

4. Ambos os lados do defletor 70mm, material de correia transportadora POM, velocidade ajustável, com o inversor. O tempo de limpeza depende da velocidade real.