PRODUCTS LIST

Automatic Cassava Flour Production Line With 98% Yield Rate

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | HUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | Cutomized |

Automatic Cassava Flour Production Line With 98% Yield Rate is a fully automatic deep processing system based on the internationally advanced “wet processing + multi-stage separation” process, specially designed for major cassava producing areas around the world, such as Nigeria, the Democratic Republic of the Congo, and Thailand. The system uses technologies such as efficient rasper chopping, 16-stage cyclone separation, filter pressure dehydration, and negative pressure flash drying to increase the cassava starch extraction rate to more than 98%, completely releasing starch resources. It can also ensure that the product powder is white, low in impurities, and hygienic and safe, effectively meeting the export market and local food safety standards.

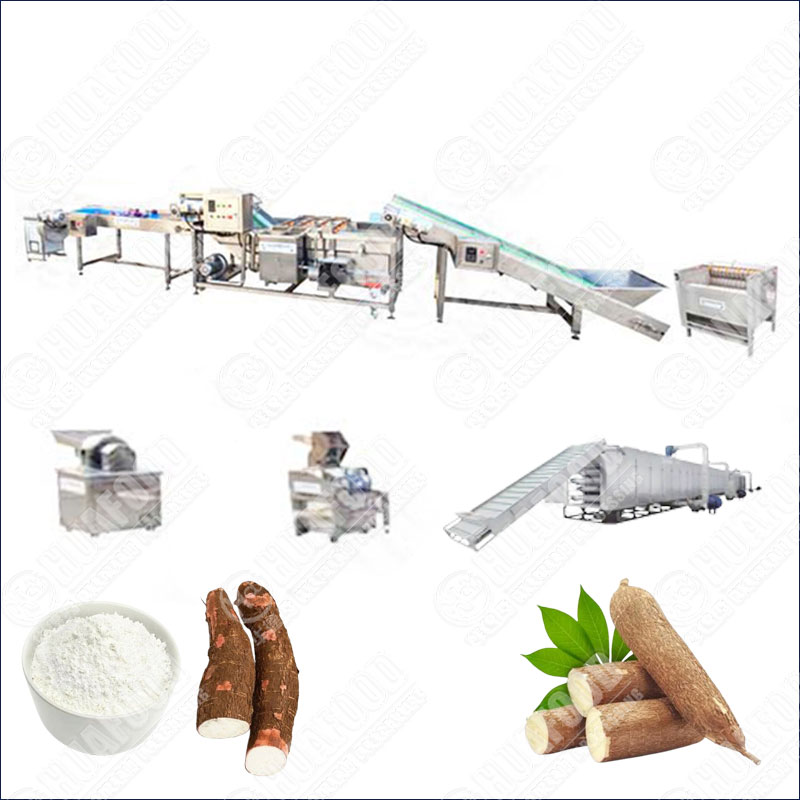

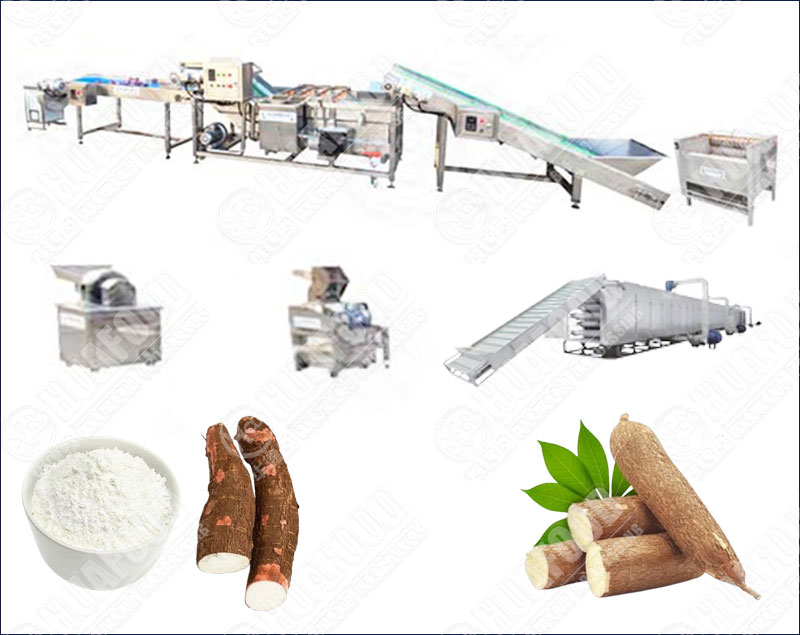

Cassava Flour Processing Process

Cassava washing → peeling → slicing → grinding → dehydration → drying → grinding → screening → packaging

Cleaning machine: high-pressure spraying and drum cleaning are integrated to completely remove mud and impurities to ensure subsequent quality.

Peeling machine: Automatically peel cassava skin, high efficiency, low breakage rate, and effectively protect the integrity of the root tuber.

Slicing machine: Uniform slicing, adjustable thickness, improve refining efficiency, and ensure powder consistency.

Pulper grinding machine: adopts double roller high-speed grinding to achieve fine pulp and efficient starch separation.

Dehydrator: high-speed centrifugal dehydration, quickly remove excess water, and reduce drying energy consumption.

Dryer: continuous belt or hot air circulation drying, precise temperature control, avoid starch discoloration.

Grinding machine: multi-stage crushing to fine powder level to ensure uniform cassava flour particles.

Screening machine: precise vibration screening, multi-layer filtration, can screen out impurities and grade products of different particle sizes.

Automatic packaging machine: supports quantitative, sealing, and labeling in one stop, realizing unmanned operation of the entire line.

Video

Cassava Flour Production Line Advantage

Reduce costs: Automation reduces labor input, and 98% extraction rate significantly increases profits.

Quality assurance: Strict temperature and humidity control at each node, clean production, pure powder.

Energy saving: Low energy consumption in dehydration and drying, adapting to local electricity or gas conditions.

Cassava Flour Processing Line Features

High yield: the whole line is optimized to achieve up to 98% cassava starch extraction rate.

Automation: from cleaning to packaging, the whole chain is mechanized, without frequent manual intervention, stable and efficient.

Strong adaptability: designed for the characteristics of tropical cassava raw materials, the equipment is anti-blocking, anti-corrosion and durable, suitable for production areas such as Nigeria, Indonesia, and Thailand.

Evidence

Feedback from the use of similar equipment in Nigeria: 45% reduction in labor and 30% reduction in overall energy consumption.

Indonesian users have a very high evaluation of the automatic packaging system: “The packaging is accurate and stable, saving 20% of packaging materials.”

In the pilot project in northeastern Thailand, an average of 70 tons of cassava raw materials are produced daily, which can be processed into 62 tons of dry powder, with a yield of 98%.

Conclusion

This Automatic Cassava Flour Production Line with 98% Yield Rate breaks the bottleneck of traditional cassava flour production efficiency, especially suitable for high-yield areas such as Nigeria, Thailand, and Indonesia-it has a high degree of automation, significant efficiency, excellent quality, energy saving and environmental protection, and is the only choice for deep processing enterprises to upgrade and transform. Leave a message online now to learn more about equipment details, customized solutions and quotations, and move towards a new era of high yield and high efficiency! 📩