PRODUCTS LIST

Customizable Chilli Sauce Production Line – Multi‑Pack Formats

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | HUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | Cutomized |

| Application | It is suitable for tomato, chilli, garlic ,ginger, carrot paste/sauce/puree making. |

This customized chili sauce production line is specially designed for processing hot chilli (extra spicy chili), covering everything from raw chili processing to various packaging forms (bottles, cans, tubes, bags). Its core is: to retain the high heat and bright color of the chili to the greatest extent, while having highly automated, modular and scalable capabilities, helping you create market-competitive chili sauce products.

Chilli Sauce Manufacturing Process

Raw material pretreatment → Chili grinding/chopping → Mixing → Heat sterilization → Filling and sealing → Cooling → Packaging → Warehousing

Chili stalk peeling machine: Efficient stalk removal, reducing chili loss, suitable for a variety of hot chilli varieties;

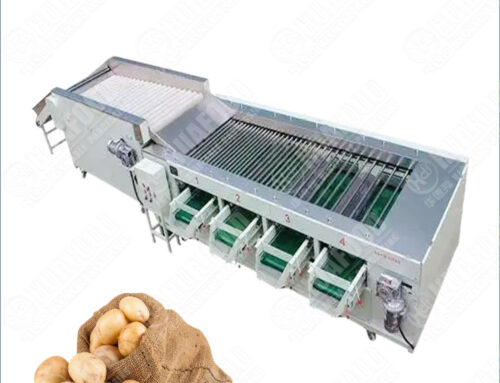

Cleaning and sorting machine: 304 stainless steel structure, bubble + spray double-effect cleaning, ensuring hygiene;

Blanching machine: Soften the chili pulp, effectively fix the natural red and spicy taste;

Crushing/grinding machine: The fineness can reach 100-200 mesh to ensure uniform penetration of spicy taste;

High shear batching tank: Accurately mix hot chili and auxiliary materials to maintain heat and flavor stability;

Homogenization and degassing system: High pressure treatment, remove bubbles, prevent oxidation, bright red color;

Tube/tank sterilization equipment: Instant high temperature sterilization, extend shelf life and retain capsaicinoids;

Automatic filling-sealing-labeling system: High hot filling accuracy, support for a variety of specifications, in line with GMP standards;

Video

Hot Sauce Production Line Features

All 304 stainless steel food grade material: corrosion resistant, safe and easy to clean;

Supports multiple packaging formats such as bottles/bags/tubes: flexibly meet the diverse needs of the market;

Modular design: blanching, homogenization, degassing, multi-format filling and other modules can be configured according to production needs;

High shear crushing and homogenization system: achieve 100-200 mesh crushing and 2-60μm homogenization to ensure consistent taste and spiciness;

Pepper Sauce Production Line Advantages

Easy-to-clean CIP design: reduces the risk of cross-contamination and saves cleaning time;

Highly automated: PLC/HMI control, reduces manual intervention, high efficiency and low error rate;

Keep spicy and color: blanching + rapid sterilization process protects capsaicinoids and chili red pigment;

Capacity can be expanded: supports 500-10000L/H expansion, suitable for customers of different sizes;

Chilli Sauce Processing Line Benefits

Cost reduction: automation replaces manual labor, saving labor costs and increasing production

High quality consistency: each bottle is mellow and hot, with a uniform flavor, enhancing brand reputation

Safety and compliance: materials are hygienic, sterilization is reliable, and complies with international food regulations

Strong market expansion: multi-packaging support helps new product development and adapts to various market segments

Conclusion

This Customizable Chili Sauce Production Line – Multi‑Pack Formats is designed specifically for hot chilli. It not only retains the original heat and bright color of the chili, but also supports highly automated and multi-specification flexible packaging. The modular and CIP design makes it easy to expand production and maintain, and is an ideal solution for modern chili sauce companies to upgrade and transform and seize the spicy market.

📩 Leave a message online now to get a customized solution and quotation to make your chili sauce production more efficient and outstanding!