PRODUCTS LIST

Automatic Grape Bubble Washing Machine with Spray & Circulation Function

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | HUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | Customized |

| Cleaning type | Apple, sand fruit, begonia, wild berry, loquat, hawthorn, hawthorn, pear, cypress, rose hip, rowan tree, apricot, cherry, peach, plum, plum, blackberry, strawberry, pineapple raspberry, orange, orange, Lemon, grapefruit, banana, banana, date, grape, grape Blueberry, mango, kiwi, bayberry, persimmon, mulberry, fig, jackfruit, milk fruit, dragon fruit, lychee, longan, coconut, betel nut, mangosteen, avocado, wolfberry, cherry tomatoes, akobi |

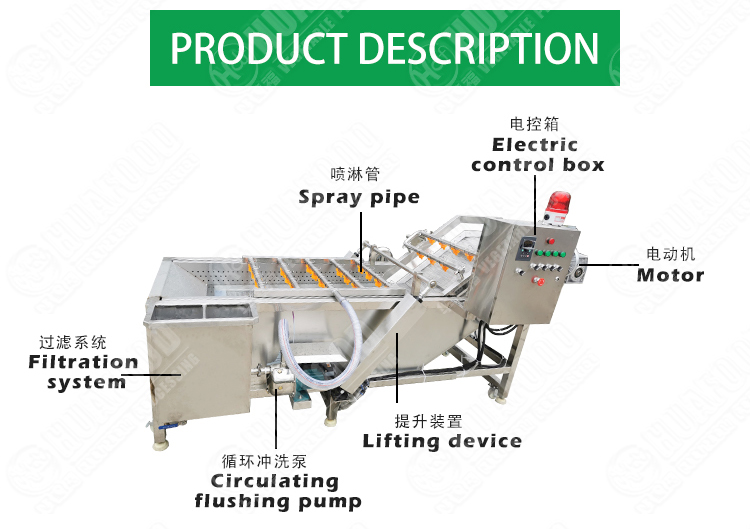

The Automatic Grape Bubble Washing Machine with Spray & Circulation Function is specially designed for gentle yet efficient cleaning of grapes. Grapes are delicate fruits with thin skins and surface bloom (wax / natural film), so this machine uses a combination of air bubbles, spray jets, and water circulation to thoroughly remove dust, impurities, pesticides, and foreign particles, while preserving grape integrity, color, and freshness. It is ideal for fresh table grapes, raisin grapes, juice grapes, export grapes etc.

Grape Washing Machine Parameter

|

Product name

|

Automatic Lifting Air bubble washing machine

|

|

External dimensions

|

2500*1000*1300MM

|

|

Weight

|

250KG

|

|

Output

|

500KG/H

|

|

Power

|

3.75KW

|

|

Power supply

|

380V

|

|

Use

|

Suitable for cleaning leafy vegetables, rhizomes and pickled fruits and vegetables

|

Grape Fruit Washer Machine Working Principle

The grape washing process in this bubble washing machine can be divided into the following steps:

Grape Feeding/Uniform Dispersion

Grapes enter the water tank via a conveyor belt or feed port and are evenly distributed in the water, either floating or settling.

Bubbling Rise/Agitation

An air pump/air pipe installed at the bottom injects air into the water tank, generating a large number of fine bubbles. These rising bubbles disturb the water flow, gently agitating the grapes and effectively loosening dust, sand, insect eggs, and other debris adhering to the grape skins. This method is similar to the “bubble rinse/float wash” mechanism, also known as bubble float wash or air wash.

Spraying/Circulating Water Flushing

At the same time, a spray pipe/nozzle system installed on the top or side sprays the floating grapes with high-pressure or low-pressure water to remove loosened impurities. The water used is typically sourced from a circulating water tank and continuously filtered and reused through a filtration/aeration/circulation pump system.

Lifting/Discharging

The cleaned grapes are lifted out of the trough along a conveyor chain or belt, sprayed or spun, and then sent to sorting, packaging, drying, or other processing steps.

Drainage/Circulation System

A sewage outlet and a residue filter system are located at the bottom to remove floating residue and sediment. Some equipment also supports water circulation, water replenishment, and automatic filtration to reduce water consumption and environmental emissions.

This “bubble + spray + circulation” triple-action system achieves efficient cleaning while minimizing mechanical impact on the grape skins.

Video

Fruit Washing Machine Application

Continuous fruit and vegetable washing machine is a product developed according to market demand. It is used to wash herb,stem and leaf vegetables such as mushrooms, celery, spinach, cabbage, etc. and root and stem fruits and vegetables such as apples, tomatoes, peppers, eggplants, cucumbers, strawberries, etc. It is widely used in vegetable processing industry and canteens of factories, mines, troops, hospitals, colleges and universities, etc.

Grape Washing Machine Features

Bubble Rinse/Gas Agitation System: A bottom air pump creates air bubbles in the water, gently stirring and cleaning the grapes.

Spray/High-Pressure Water System: Multiple spray pipes/nozzles are installed to spray the grapes from different angles, further removing debris and pesticide residues.

Circulating Water/Filtration System: Water is recycled after filtration, sedimentation, and rehydration, saving water and protecting the environment.

Food-Grade Stainless Steel Construction/Easy-Clean Design: The machine body and contact parts are constructed of SUS304/SUS316 stainless steel, which is corrosion-resistant, easy to clean, and meets food hygiene standards.

Adjustable Speed/Discharge Method: The conveying, bubble, and spray flow rates are adjustable to accommodate grapes of different varieties, sizes, and contamination levels. Optional discharge methods include chain lift and mesh belt lift.

Grape Fruit Washing Machine Advantages

Efficient Cleaning / Strong Decontamination Capabilities

The combined effects of air bubble agitation and spray rinsing remove dust, insect eggs, debris, and pesticide residues for a more thorough cleaning.

Low Damage / Gentle Treatment

Compared to traditional brushing and high-flow water impact methods, the air bubble method is gentler on thin-skinned grapes, reducing skin damage, bruising, and cracking.

Water Saving / Reduced Operating Costs

The circulating water design and automatic filtration system reduce water consumption and wastewater discharge, lowering water consumption and treatment costs.

Automation / Easy Integration

Can be seamlessly integrated with subsequent equipment such as grading, packaging, and drying, serving as an automated fruit washing step in the entire production line.

Grape Cleaning Machine Features

Improve product quality and appearance

Through cleaning, smooth skins, and no contamination or damage, deliver high-quality grapes, making them more receptive to market and export standards.

Reduce labor costs / Improve production efficiency

Fully automated operation replaces manual cleaning, reducing labor input and increasing processing capacity and efficiency.

Reduce waste / Improve yield

Less breakage and damage increases yield, reducing waste and substandard quality caused by improper cleaning.

Environmental protection and energy saving / Compliant drainage

The circulating water system reduces water consumption, facilitating wastewater treatment, and meeting environmental and food processing plant standards.

Conclusion

In short, the Automatic Grape Bubble Washing Machine with Spray & Circulation is a washing machine specifically designed for grapes, which have thin skins, are fragile, have natural dust on the surface, and are easily contaminated. It utilizes a combination of bubble rise, spray rinsing, and water circulation filtration to achieve gentle yet effective grape surface cleaning. Its stainless steel construction and adjustable controls provide a reliable fruit washing solution for export-grade grapes, fresh-eating grapes, wine grapes, and fruit packaging. It balances efficiency, fruit integrity, water conservation, and automation, making it an indispensable component of modern grape processing lines.

If you would like to receive detailed technical specifications, capacity configurations, selection options, customer case studies, or video demonstrations of this grape bubble washing machine, please contact us online. We will provide you with professional, customized solutions and technical support to help you improve the quality and efficiency of your grape production.