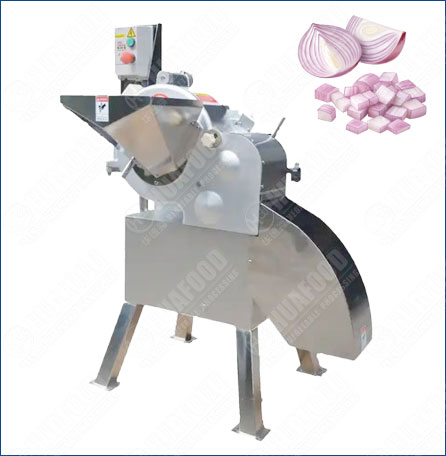

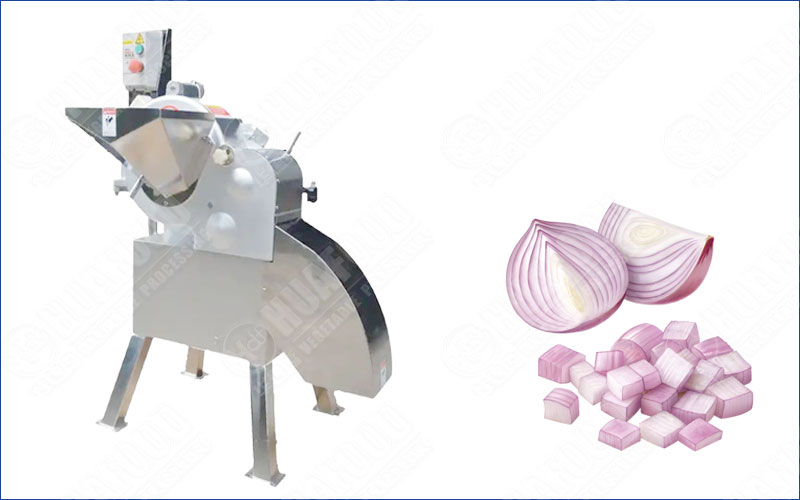

Electric Onion Dicing Machine With 304 Stainless Steel for Uniform Cubes

In the food processing industry, onions have always presented a challenge in manual processing due to their multi-layered structure, high water content, and eye-irritating properties. To achieve efficient, high-volume dicing with highly uniform cube sizes, we have introduced the Electric Onion Dicing Machine with 304 Stainless Steel for Uniform Cubes.

This onion dicing machine is an advanced three-dimensional (3D) dicing machine specifically designed to handle the unique structure of onions. It utilizes a powerful electric drive to ensure stable kinetic energy during the cutting process, preventing the onion from shattering or deforming due to insufficient power, a common problem with traditional machines. All core components of the machine are made of food-grade SUS304 stainless steel, offering excellent corrosion resistance against onion juice, ensuring long-term durability and food safety. This equipment can cut onions into uniformly shaped and precisely sized cubes, making it an ideal choice for improving dicing quality and efficiency in industries such as condiments, dehydrated vegetables, and central kitchens.

Onion Dicing Machine Working Principle

Our Electric Onion Dicing Machine utilizes a three-dimensional cutting combination principle to ensure that the multi-layered structure of the onion is simultaneously and precisely broken down into perfect cubes.

Feeding and Positioning: Pre-processed onions (such as peeled and trimmed) are fed into the machine through the feeding port. The machine is equipped with a material pressing and positioning system to keep the onions stable in the dicing area, preventing displacement or shaking during high-speed cutting.

First Dimension Cutting (Slicing): First, a set of high-speed rotating blades cuts the onion along its longitudinal axis (or vertical direction) into slices of uniform thickness.

Second Dimension Cutting (Strip Cutting): Next, these slices are introduced into a second set of disc blades or straight blades, which cut them perpendicular to the first dimension cut, dividing the slices into uniform strips.

Third Dimension Cutting (Dicing): Finally, the strips enter a third set of cross-cutting blades, completing the third dimension cut, thus forming uniform cubes with consistent size and smooth edges.

Finished Product Discharge: The diced onions are quickly discharged through the outlet, minimizing their residence time in the machine and maximizing the preservation of the onion’s freshness and structural integrity.

Onion Cutting Machine Advantages

Achieves Uniform and Perfect Dicing Results: 3D cutting technology ensures high consistency in the shape of the diced pieces, greatly improving the commercial value and dehydration efficiency of the final product.

Greatly Reduces Manual Irritation and Labor Intensity: Automated machine cutting isolates the irritating odor of onions within the work area, protecting operators and completely eliminating the need for high-intensity manual dicing labor.

Superior Corrosion Resistance and Hygienic Performance: SUS304 material effectively resists corrosion from onion juice, is easy to thoroughly rinse and disinfect, and fully complies with international food safety standards.

Extremely Low Material Breakage Rate: Stable electric drive and sharp blades, combined with a precise positioning system, ensure a clean and precise cutting process, minimizing onion breakage or leakage.

Onion Dicer Features

3D Synchronous Precision Cutting System: Utilizes three sets of blades working in coordination to achieve simultaneous, multi-dimensional cutting of onions, ensuring that the resulting onion dices are uniform in size in all three dimensions (length, width, and height).

High-Strength SUS304 Stainless Steel Structure: Uses food-grade SUS304 stainless steel for the machine body and material contact surfaces, providing excellent acid and alkali resistance and corrosion resistance, effectively resisting the corrosive effects of onion juice.

Powerful and Stable Electric Drive: Employs an industrial-grade motor to provide stable power, ensuring that the blades do not slow down or jam when cutting through the multi-layered fibrous structure of onions, improving cutting smoothness and precision.

Interchangeable Blade Set Design: The modular design of the blade set allows operators to quickly replace different sized blade sets (such as 5mm x 5mm or 10mm x 10mm) according to the final product requirements, enabling multi-specification production.

Onion Dicing Machine Benefits

Significantly Increased Production Efficiency and Throughput: Compared to manual dicing, the machine can process several times the amount of onions in a short time, quickly meeting the demands of large-scale orders.

Reduced Waste and Increased Yield: The precision of mechanical cutting is far superior to manual cutting, resulting in minimal waste and scraps during the dicing process, directly improving raw material utilization and economic efficiency.

Product Quality Standardization and Consistency: Uniform dicing size is crucial for the success of subsequent dehydration, freezing, or cooking processes. The machine ensures high consistency in product quality across all batches.

Accelerated Return on Investment (ROI): By reducing labor costs, increasing output, and minimizing waste, the equipment can recoup its investment cost in a short period.

Conclusion

Our Electric Onion Dicing Machine with 304 Stainless Steel for Uniform Cubes is an industrial-grade 3D dicing machine specifically designed for efficient and precise onion processing. With its superior SUS304 hygienic quality and highly consistent dicing results, it helps you completely overcome the drawbacks of manual dicing, achieving a double leap in production efficiency and product quality.

Say goodbye to inefficient manual dicing and irregular scraps!

Contact our professional team today, leave a message online to get detailed technical specifications, blade set options, and exclusive pricing for this 3D onion dicing machine! Let us help your onion processing business reach new heights!