LISTA DE PRODUTOS

Máquina de filtro de óleo de palma de vácuo contínuo para filtração de óleo comestível

Detalhes do produto:

| Lugar de origem: | Zhengzhou,Henan,China |

|---|---|

| Marca: | HUAFOOD |

| Certificação: | ISO,CE,GV |

| Número do modelo: | HQC-612D |

| Material de filtro: | fritura de cozinha usada, coco, amendoim, Palma, soja, sésamo, girassol, rícino, culinária, Oliva, mostarda |

|---|---|

| Profundidade do filtro: | 5-filtração de camada |

| Princípio: | Centrífuga a vácuo |

| Efeito de filtro: | 99% |

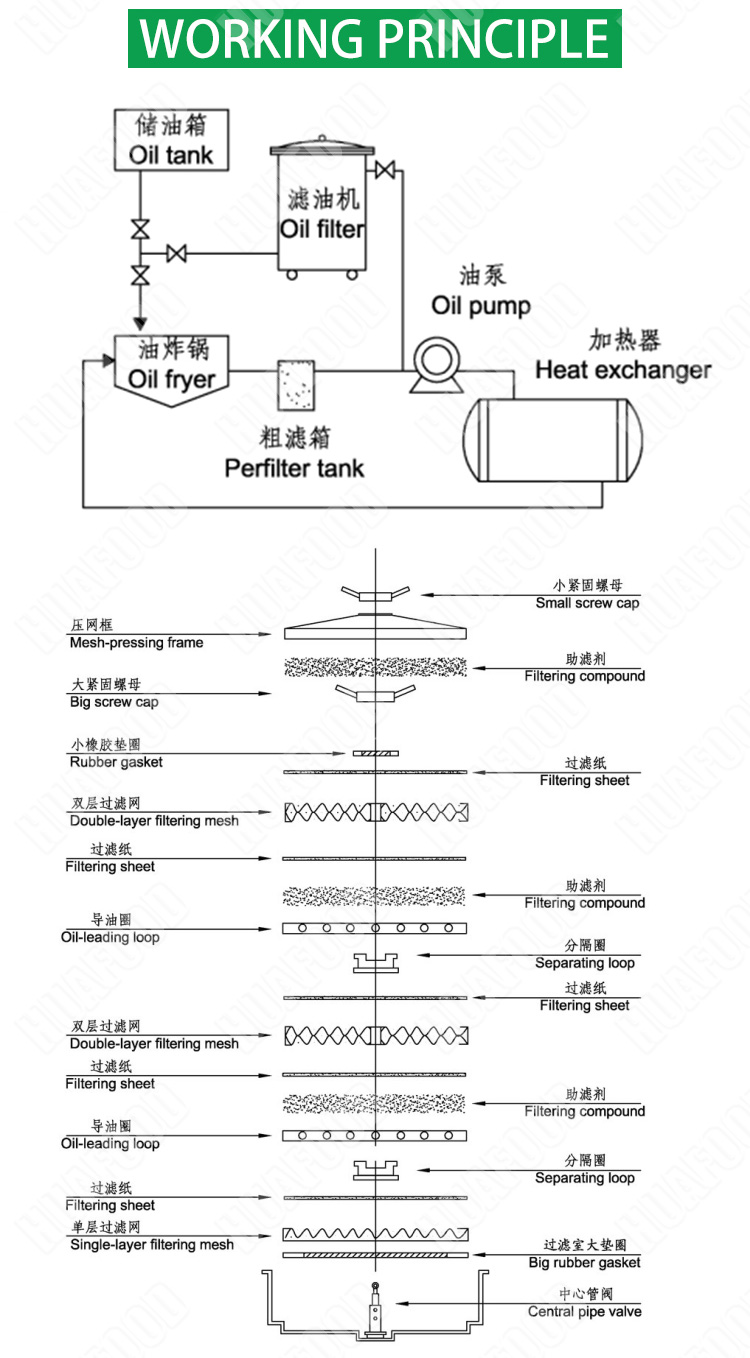

Continuous Vacuum Palm Oil Filter Machine for Fried Cooling Edible Oil Filtration is a continuous vacuum filtration equipment designed for palm oil and oil products after high-temperature frying and cooling. It integrates vacuum degassing and dehydration, spray atomization, five-stage precision filtration and cooling functions. It can continuously remove moisture, gás, carbon dust and fine suspended matter in the oil without interrupting production, effectively improving the clarity, color and flavor of palm oil, and meeting the stringent requirements of high-quality edible oil production.

Vídeo

How Do Air Showers Work & Parâmetros

Oil extraction and heating: The equipment extracts high-temperature oil from the fryer or cooling tank and heats it to a suitable temperature to vaporize the water and gas in the oil.

Vacuum spray dehydration and degassing: In a vacuum environment, the oil is atomized by a spray system, so that the water vapor is quickly vaporized and extracted to the condensation system.

Multi-stage filtration and impurity reduction: The oil first collects large particles (such as dough and carbon chips) through coarse filtration, and then removes particles, pigments and odors through fine filtration and adsorption media to achieve high-precision purification.

Cooling and circulation: After the filtered oil is cooled to the target temperature through the cooling unit, it is circulated back to the oil tank or oil storage system to achieve continuous production.

Cooking Oil Filter Machine Parameters

| Modelo | HLY63-A | HLY125-A | HLY125-A |

| Número de camadas de filtro | Tipo de cinco segmentos | Tipo de cinco segmentos | tipo de três segmentos |

| Quantidade de filtragem de óleo | 30L/min | 80L/min | 80L/min |

| área de filtro | 1.03m2 | 2.0eu2 | 1.2eu2 |

| pressão de saída | 0.5MPa | 0.5MPa | 0.5MPa |

| Poder | 1.5kw | 3.0kw | 3.0kw |

| Peso | 180kg | 550kg | 550kg |

| Tensão | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Diâmetro do tubo de entrada de óleo | 1.0 polegadas | 2.0 polegadas | 2.0 polegadas |

| Diâmetro do tubo de saída de óleo | 1.0 polegadas | 1.5 polegadas | 1.5 polegadas |

| Tamanho da máquina | 850*850*1100milímetros | 1100*1000*1300milímetros | 1100*1000*1300milímetros |

Aplicativo

Máquina de filtro de óleo de cozinha para fritadeira

Máquina de filtro de óleo de cozinha para fritadeira

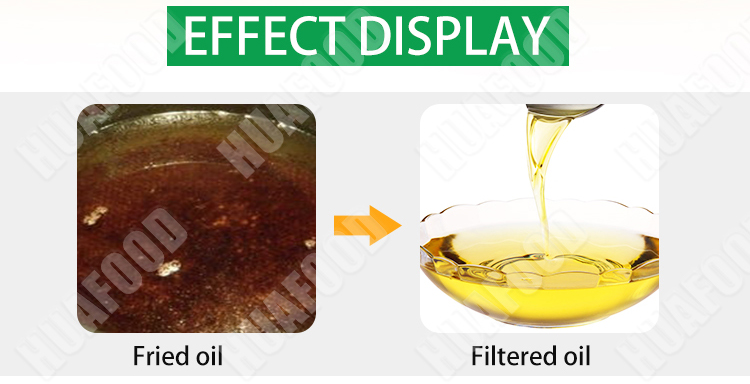

Como sabemos, processo de produção de alimentos terá muito tempo de óleo para fritar , e a qualidade diminuirá gradualmente. produtos fritos parecem pretos, o cheiro de óleo, alto teor de óleo, o valor de ácido e o valor de peróxido são excedidos, fumaça e assim por diante. Afeta muito a percepção do cliente sobre os alimentos. E também traz problema de higiene e segurança alimentar. Portanto, o óleo de fritura deve ser substituído após um período de uso, no entanto, substituir frequentemente o óleo de fritura aumentará os custos de produção. O uso de equipamento de filtragem de óleo de fritura HFD será capaz de resolver os problemas acima. Máquina de filtro de óleo de fritura pode prolongar a vida útil do óleo, economizando o custo do petróleo.

Características

Filter cake oil content control

Resistance sensor accuracy ±0.5%

Dynamically adjust nitrogen purge duration

Three-stage vacuum gradient system

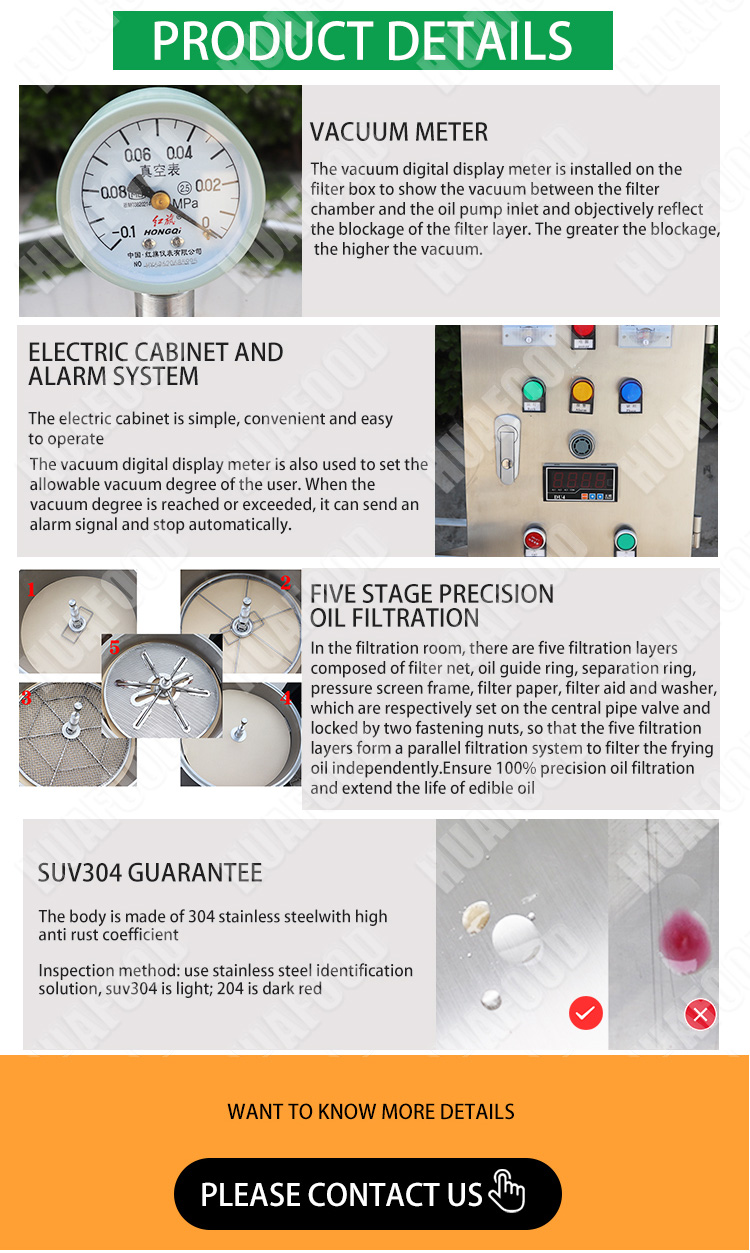

Adaptive adjustment of vacuum degree (-0.08 ~ -0.092 MPa)

Matching viscosity changes at 80-95℃ (45→18 cP)

Nitrogen inerting sealed cabin

Real-time monitoring of oxygen content <50 ppm

Protection of unsaturated fatty acids such as oleic acid (39-45%)

Shear-resistant titanium alloy filter blades

Surface hardening (38 HRC) to resist palm oil residue abrasive particles (>80μm silica)

Filter cloth-free design eliminates tearing risk in CPO filtration

Benefícios

– Reduce oil oxidation and rancidity, improve flavor, color and consumer experience;

– High degree of automation in continuous operation, reducing manual operation costs;

– Significantly reduce moisture and free gas in palm oil, extending storage and service life;

Conclusão

“Continuous Vacuum Palm Oil Filter Machine For Fried Cooling Edible Oil Filtration” integrates vacuum spray dehydration, precision five-stage filtration and oil cooling to specifically meet the requirements of palm oil and its characteristics during frying and cooling. It not only improves filtration accuracy, but also greatly extends the oil life cycle, significantly reduces replacement costs, and helps oil mills and large kitchens achieve efficient, intelligent, energy-saving and more environmentally friendly oil management.

Leave a message online now to get detailed technical parameters, capacity selection, degree of automation and quotation solutions for the equipment. Our professional engineering team will provide you with customized consultation and project support within 24 horas!

700-500-6.jpg)

700-500-5.jpg)

700-500-4-1.jpg)