PRODUCTS LIST

Stainless Steel Peeler Onion Peeling Machine For Skin Removing

Product Details:

| Place of Origin: | Henan Huafood, China |

|---|---|

| Brand Name: | HUAFOOD |

| Certification: | ISO,CE,SGS |

| Model Number: | Cutomized |

| Application | widely used in the vegetable processing industry. |

Introduction

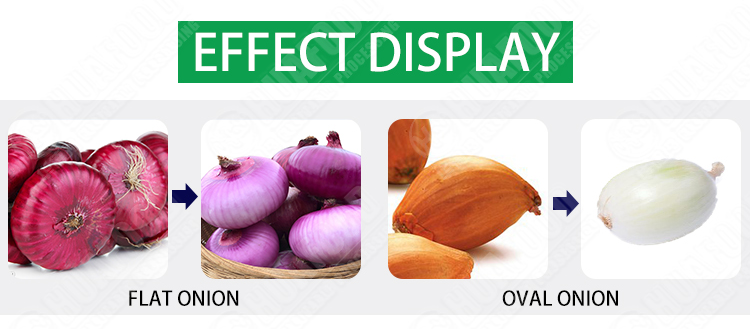

The Stainless Steel Onion Peeling Machine is an automated solution engineered to strip both first and second skins from onions without damaging the bulb.It accommodates onions ranging from 45 mm to 105 mm in diameter and processes up to 3,000 units per hour, significantly outpacing manual peeling methods.

|

Model

|

HYC-500

|

|

Uploading

|

3 belts

|

|

Size

|

2150*1150*2000mm

|

|

Power Supply

|

380V, 50HZ,3PH

|

|

Gas source

|

More than 1.0MPa

|

|

Power

|

1.52Kw

|

|

Output

|

1500-2000kg/h

|

|

Weight

|

320kg

|

Video

Working principle

The onion peeling machine adopts the processing method of peeling without cutting roots. In this way, the peeled onions are small in peel volume, high in yield, and the interior is clean and hygienic without pollution. It is required that the onions in any state can be peeled at one time and removed cleanly. The machine has been widely used in the vegetable processing industry.

Features

1. Full 304 Food-Grade Stainless Steel Construction

All contact parts—including drums, blades, and frames—are fabricated from SUS304 stainless steel, ensuring corrosion resistance and hygienic operation.

2. Pneumatic/Air-Jet Peeling System

Utilizes compressed air directed through multi-port skinning wheels or pneumatic rollers to gently remove outer layers without frictional damage, preserving onion integrity .

3. Variable Speed & Depth Control

Equipped with a frequency inverter, operators can fine-tune peeling speed (500–1,500 rpm) and adjust air pressure (0.8–1.0 MPa) to suit dry or wet onions and control peel depth from 0.2 mm to 0.5 mm .

4. Continuous Conveyor Feed

A food-grade belt transports onions through the peeling chamber in a smooth, uninterrupted flow, enabling capacities from 600 kg/h up to 2,500 kg/h depending on the model .

5. Quick-Release Modular Blades & Drum

Modular peeling drums and blade assemblies snap in and out without tools, facilitating rapid changeover between batches and simplifying sanitation procedures ;

Advantages

①The onions do not need to be graded, and they can be peeled regardless of their size, wetness and dryness. .

②Skinning automation, one-time automatic completion and clean peeling.

③The “cortex controller” can control the depth of the peeling layer freely, and only peeling the skin or peeling the second skin can be achieved.

④The machine uses stainless steel 304, with long life and strong anti-rust ability.

Benefits

Labor Savings: Replaces 8–10 workers per shift, saving up to $5,000/month in labor costs;

Consistent Product Quality: Uniform peeling enhances downstream slicing, dicing, and dehydration processes, improving overall yield and appearance;

Reduced Downtime: Modular parts and pneumatic systems minimize clogging and mechanical wear, delivering over 16 hours/day of reliable operation;

Enhanced Food Safety: Closed-loop stainless steel design with quick-release components enables thorough CIP (clean-in-place) cleaning, meeting CE, FDA, and ISO 22000 standards;

The Stainless Steel Peeler Onion Peeling Machine For Skin Removing merges robust 304-grade construction, energy-saving pneumatic peeling, and user-friendly controls into an all-in-one solution for modern food processors. It delivers unmatched efficiency, quality consistency, and sanitary operation—ideal for restaurants, canteens, dehydrated food manufacturers, and large-scale catering operations.

Ready to elevate your onion processing line?

👉 Leave us an online inquiry today for detailed specifications, custom configurations, and a competitive quote!